You’ve seen it a hundred times. A vehicle comes in with abnormal wear on a front tire. It looks like camber wear. One shoulder is badly worn, but the other front tire appears to be OK. You put it on your alignment machine and check camber and toe. Sure enough, camber on the wheel with the worn tire is out of specifications. You visually inspect the suspension for obvious signs of wear or damage like collapsed control arm bushings, a bad ball joint, or a weak or broken spring, but you find nothing. You assume the front end is out of adjustment, so you reset camber to specifications and send the customer on his or her way.

Did you fix the problem?

Probably not. If camber, caster or toe are out of specifications, there is usually an underlying reason why. Something may be bent, worn or mislocated.

Take a bent steering arm, for example, which will change toe alignment. Only 1/8-inch of toe misalignment produces scrub that’s equivalent to dragging the tire sideways 28 feet for every mile that’s traveled! So, if you see a feathered-wear pattern on the tires, or what looks like camber wear on the inside or outside shoulders of both front tires, toe is probably out of alignment. Shoulder wear on both outside edges can be caused by toe-in, while shoulder wear on both inside edges can result from toe-out.

Toe misalignment is most often due to worn tie rod ends, but it can also be caused by bent steering arms, a bent tie rod, or even a bent spindle, control arm or strut. If toe is off, therefore, don’t assume a simple adjustment is all that’s needed.

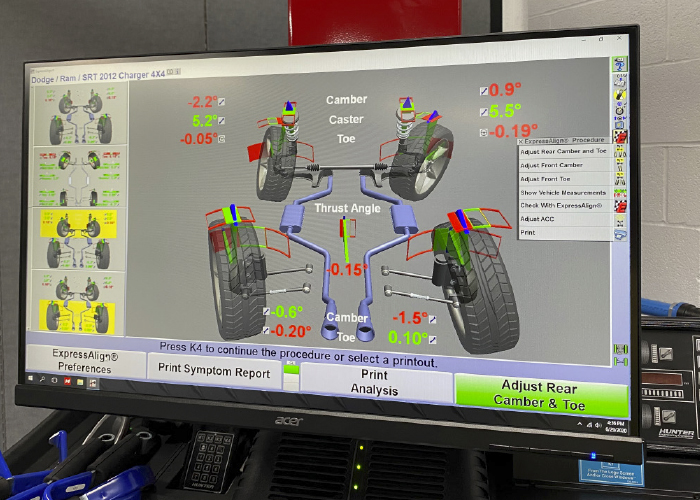

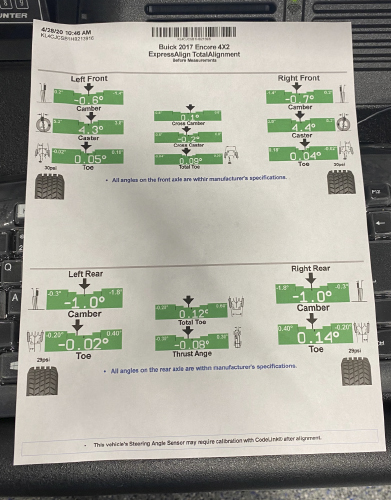

Visually inspect the steering linkage and suspension for any obvious signs of damage, check the tie rod ends for play, check the suspension bushings and then hook up your alignment equipment and check toe, camber, caster, SAI and toe-out on turns.

Checking toe-out on turns will tell you whether or not a vehicle has a bent steering arm. When the wheels are turned the same number of degrees to the right and the left, the change in toe-out should be the same on both sides. If it’s not, one or both arms are probably bent.

Pulling down on the suspension and checking for uneven toe changes side-to-side is yet another “trick” that can be used to find this kind of “hidden” damage. If a steering arm is bent, one side will show a greater toe change than the other.

CAMBER CLUES

Tire wear also can be affected by camber. Excessive camber loads on one side of the tread can produce uneven wear. If the inside of the tread is worn, the wheel has too much negative camber. A worn outer tread indicates too much positive camber.

Camber can also affect directional stability. A vehicle will lead toward the side with the most camber. So always compare camber readings on both sides. More than half a degree difference can cause a steering pull.

If camber is off on only one side, a close encounter with a pothole or curb may have bent a spindle, control arm or strut. A shift in the position of a strut tower can cause the same thing. A shift in the position of a crossmember, on the other hand, will usually change camber on both sides. In MacPherson strut suspensions, the position of the upper strut tower is critical. Too far in and the wheel will have too much negative camber. Too far out and it will have too much positive camber. A bent strut or spindle can affect camber, as can a bent control arm, a mislocated crossmember or an off-center engine cradle in a FWD car.

One way to identify hidden damage that may be affecting camber is to do a “jounce/rebound camber check.” Raise the suspension four inches and read camber on both sides. Then, compress the suspension four inches and again read the camber angles for both wheels.

Different side-to-side camber readings with a jounce/rebound camber check usually indicate a bent strut that needs to be replaced or straightened. If the readings are the same, a check of the “steering axis inclination” (SAI) angle side-to-side should also be made.

SAI, THE DIAGNOSTIC ANGLE

SAI is a “built-in” angle that can help you detect all kinds of hidden damage. SAI is the angle of the steering axis that runs from the center of the upper ball joints or strut towers through the center of the lower ball joints. SAI should always be the same on both sides. A difference of more than a degree usually indicates a mispositioned strut tower, bent spindle or control arm.

To check for a bent strut shaft, loosen the large shaft nut at the top of each strut and rotate the shaft 360° while keeping an eye on the camber reading. If the shaft is bent, the top of the wheel will wobble in and out, and the camber reading will change as the shaft turns. No change in the camber reading means there’s nothing wrong with the strut. A strut with a bent shaft must be replaced. There’s no way to safely straighten this kind of damage because attempting to bend a hardened shaft will likely crack it.