One of the most controversial topics involving brake repair is where noise comes from and what can be done to prevent it. It’s simple: all brake noise starts at the point where the pad and rotor make contact. Every squeak, chirp and groan has its origins at the interface between these two components and how it is expressed through the rest of the car.

Once you understand the importance of this interface, you will understand the importance of brake rotor finish, pad selection and hardware.

Brake systems are complex and require an understanding of the root cause of generating the noise. Noisy brakes are not squeaking door hinges waiting to be lubed. You cannot simply apply a magic substance to make them quiet. It is not that using lubricants, pastes and sprays is not effective; it is simply intuitive that minimizing friction (without consideration of braking performance) using the most expedient available application is cost effective with respect to service labor.

The key to stopping brake noise is to do the brake job right the first time. If a customer does come back due to noise, a shop must create a diagnostic process to resolve the problem the first time.

What is Brake Noise?

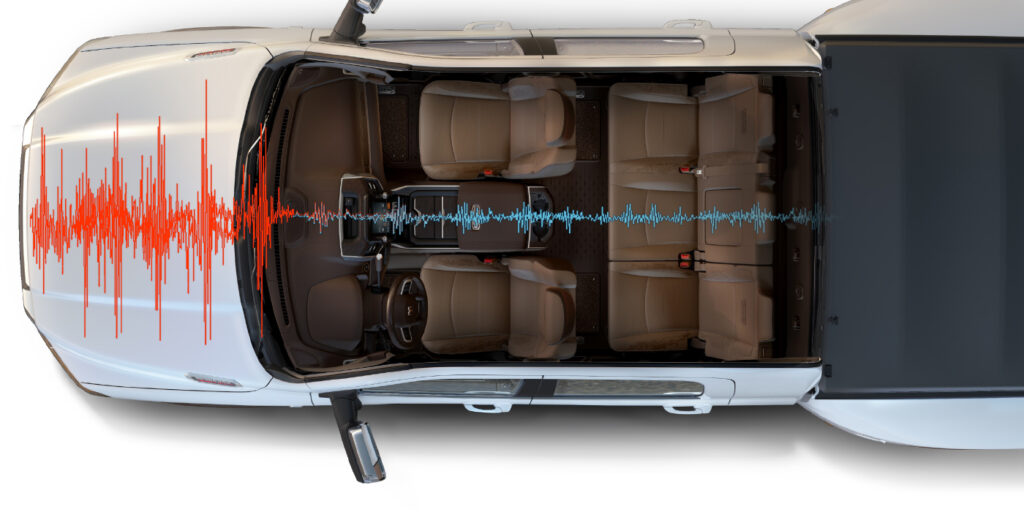

As a set of brake pads clamp down on a rotor, they start to vibrate. As the pads, rotor and even the steering knuckle vibrate, they excite the air around them. The motion/vibration of the brake system pushes the air forward, compressing it, and when the fingers pull back, they suck the air back, creating a low-pressure area.

If you were to chart the pressure change over time, it would go up and down like a wave that would repeat itself (audible cyclic frequency) until the brake system stopped vibrating. These changes in the air pressure of a sound wave eventually enter your ear because the vibration and associated frequency also move at a constant speed through the air.

This transmission and conversion of sound wave vibrations into mechanical vibration and then into nerve impulses is one of the cornerstones for understanding NVH and brake noise.

All brakes make noise. When the friction material makes contact with the rotor, the coupling causes the brake pad and rotor to oscillate and vibrate. In engineering terms, this is called “force coupled excitation,” which means that the components are locked as a combined system that will vibrate at the system’s natural frequency combined modes of vibration.

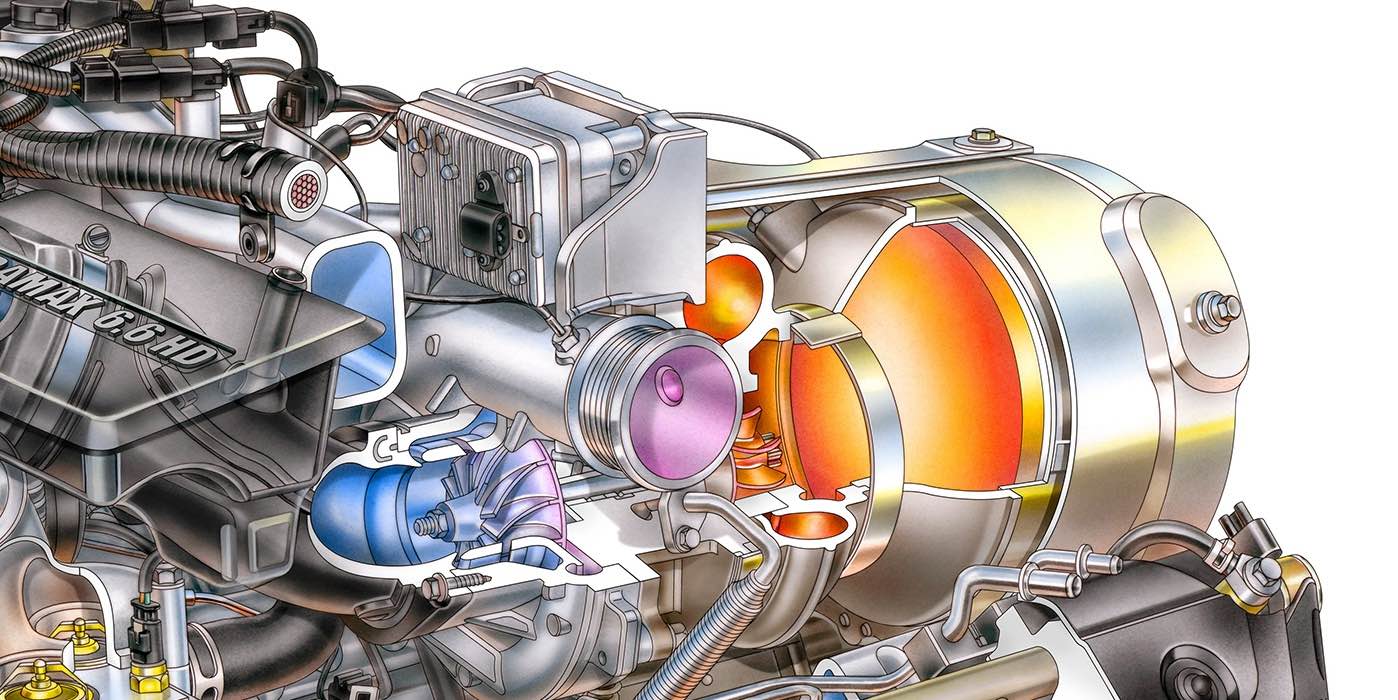

The amount of excitation and the frequency generated can be influenced by variations in brake torque (or changes in the coefficient of friction) across the rotor’s face. As the components heat up, the rotor may develop hot spots that could cause the rotor to have different regions of friction that produce different levels of brake torque. This friction coupling is where most brake noise is generated.

Stopping Noise at the Start

If you are trying to eliminate a noise, you could try to stop it from moving the air around it. To do this, you could eliminate the air all together or at least get farther away from it. This is not possible with brakes because they don’t operate in a vacuum and they cannot be separated from the vehicle.

You can suppress or eliminate the path of vibration transfer from the source leading to noise through damping and isolation methods or dissipate the noise by insulation/absorption treatment. But, the most effective method is to control the vibrations at the pad and rotor interface.

First, if a friction material is better at keeping a constant coefficient of friction across broad temperature ranges and environmental conditions, it probably is a quiet pad. A “consistent” friction material causes less vibration excitation variation at the friction coupling by having consistent brake torque at environmental extremes of humidity and temperature (-40° F to 500° F).

Second, some friction materials leave or transfer a layer of friction material (transfer film or “seasoning”) on the rotor’s surface that friction material companies claim can smooth out the rotor surface, thereby causing less excitation and noise at the friction coupling. Also, this transfer layer may not be as sensitive to heat-induced brake torque variation.

Rotors

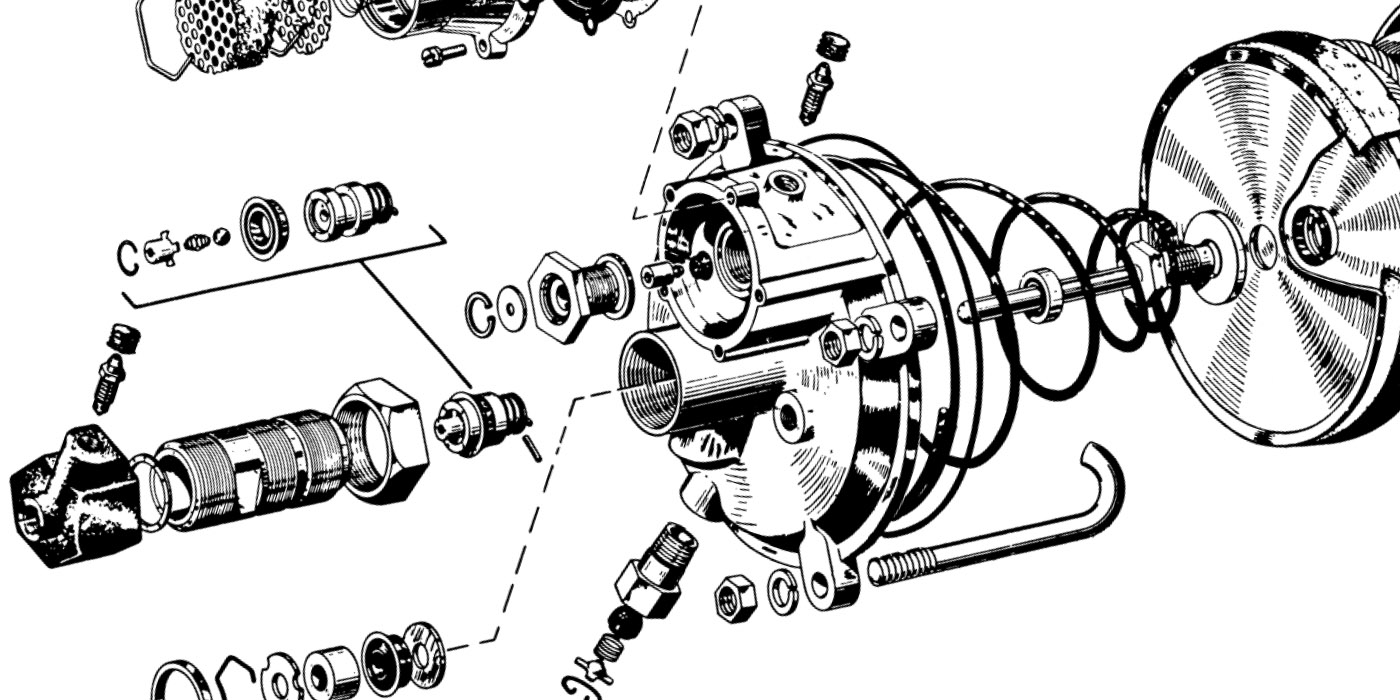

Poor rotor finish can lead to noise. When machining a rotor, you have two primary goals: Provide a smooth surface finish for the pads; and provide a true surface finish.

The smoothness of the friction surface of a rotor is described in terms of micro-finish or RA factor. RA stands for “roughness average” and represents a way to measure the smoothness of a rotor. Most lathes out there, when in good condition and used properly, will yield very acceptable RA factors. The finish is essential to transfer material for organic and ceramic friction materials. Also, the correct finish is essential for semi-metallic pads so they can have the correct coefficient of friction during initial break-in.

Non-directional finishes can help in the bedding process and the establishment of a transfer layer. It can also prevent the grooves of the rotor from pulling and pushing on the pad, like how a record moves a needle.

Pads

All brake pads must be bedded-in with the rotor they will be used against to maximize brake performance. The bedding-in process involves a gradual buildup of heat in the rotors and pad compound. But, how this gradual heat and bedding process takes place is determined by the manufacturer of the pad.

Taking a vehicle for a test drive after a brake job lays down a thin layer of transfer film onto the rotor surface. Following the bed-in procedures provided by the manufacturer will ensure a smooth, even layer of transfer film on the rotor and will minimize brake judders.

The break-in procedure is not to “cure” a pad and harden the resins. If a brake pad set produces an excessive amount of smell or smoke on the initial bedding procedure, chances are that there is something wrong with the pad and how it was manufactured.

There are no set rules or universal procedures to bedding or breaking-in brake pads. Due to the fact that every manufacturer has different manufacturing processes, each has its own recommended procedure.

Some manufacturers recommend 400 to 500 miles of moderate driving without hard stops, while some recommend 20 to 30 stops from specific speeds. Most manufacturers are printing the break-in directions and dropping them in the box.

There are no miracle products that will stop all brake noise. It comes down to the basics of having a rotor with a high-quality finish and friction material that is stable. Everything else is secondary.