EVs are not immune to potholes, curbs and rough roads. Just like every internal combustion vehicle on the roads, the shocks, struts and springs will eventually degrade to the point where they can no longer control the movement of the suspension.

Most EVs have a weight problem that works to your advantage. The weight of the battery and motor can make some EVs 1,000-3,000 pounds heavier than their internal combustion counterparts. This will cause extra stress on the suspension.

There is not that much of a difference with an EV ride control component. The changes are typically in the valving and spring rates to accommodate the extra weight. The good news is that replacement units are available from sources other than the dealer.

Air Ride

Some EVs will have an air suspension. The air ride system does more than your average system inside a non-EV. It might trim the vehicle to achieve the best aerodynamics or to overcome road obstacles.

Some of these systems can be called “smart.” For example, Tesla’s air suspension uses GPS information and vehicle speed to adjust the suspension ride height. The driver can set GPS waypoints for driveways, rough roads and other locations where the suspension needs to be raised. After a waypoint is set, the car will raise or lower automatically.

The suspension also trims the ride height depending on loads and speed. The system will lower the front at highway speeds to improve aerodynamics. The driver can select modes manually on some EVs.

Service

Good news! If you can replace a strut on a conventional vehicle, you can change the struts on an EV. Most systems do not require touching the high-voltage battery system. So, you are not required to wear insulated gloves or use insulated tools.

But, you do have to look at the service information before you lift the vehicle. Many EVs have service or tow modes allowing you to roll and spot the vehicle on the lift. Also, the service information will include the lift points and adapter required so the lift does not damage the battery pack.

If you are servicing an EV with air ride, there might be extra procedures. The most common procedure is putting the suspension into jack or service mode before lifting the car. For some procedures like strut replacement, you will depressurize the system. This will require a scan tool to actuate the valves in the system.

Nitrogen

Tesla models will use nitrogen for the air ride system. Nitrogen gas is more stable and drier than atmospheric air. In addition, the system is not completely sealed and can intake outside air, if required.

Under the access panel in the frunk, there will be a Schrader valve that can be used to add nitrogen gas to the system. The valve can be mounted on the upper chassis brace for older models and the reservoir for newer models. Tesla offers a special tool to connect a tank of nitrogen gas to the system and regulate the pressure between 8-9 bar (118-130 psi). The valve is not directly connected to the bladders on all four corners and will not change ride height. The air is directed first into the reservoir, and the valve block will then distribute the air to the units.

Tesla advises that shop air should not be applied to the service port due to moisture and contamination in compressed air. The system cannot detect whether the air inside the system is nitrogen or shop air.

Calibration

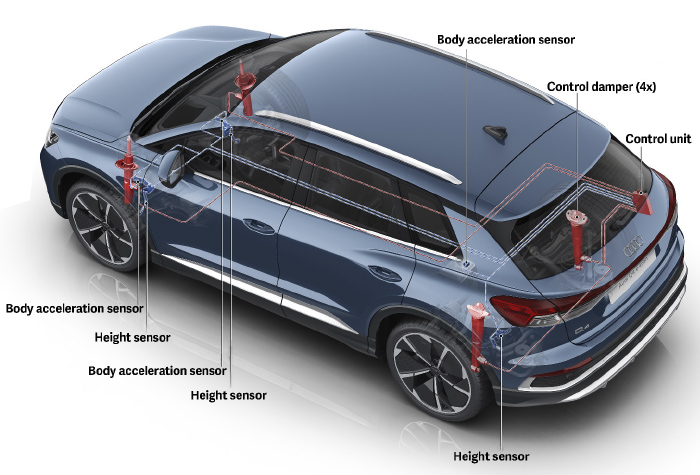

After a strut or suspension component has been replaced, it is recommended that the ride height be calibrated. This is not just for air ride; it also applies to headlights. Many EVs have ride height sensors that control the headlight’s beams. The procedure will vary by make and model. This also applies to late-model internal combustion cars and trucks. To perform the calibration, a scan tool will likely be required.