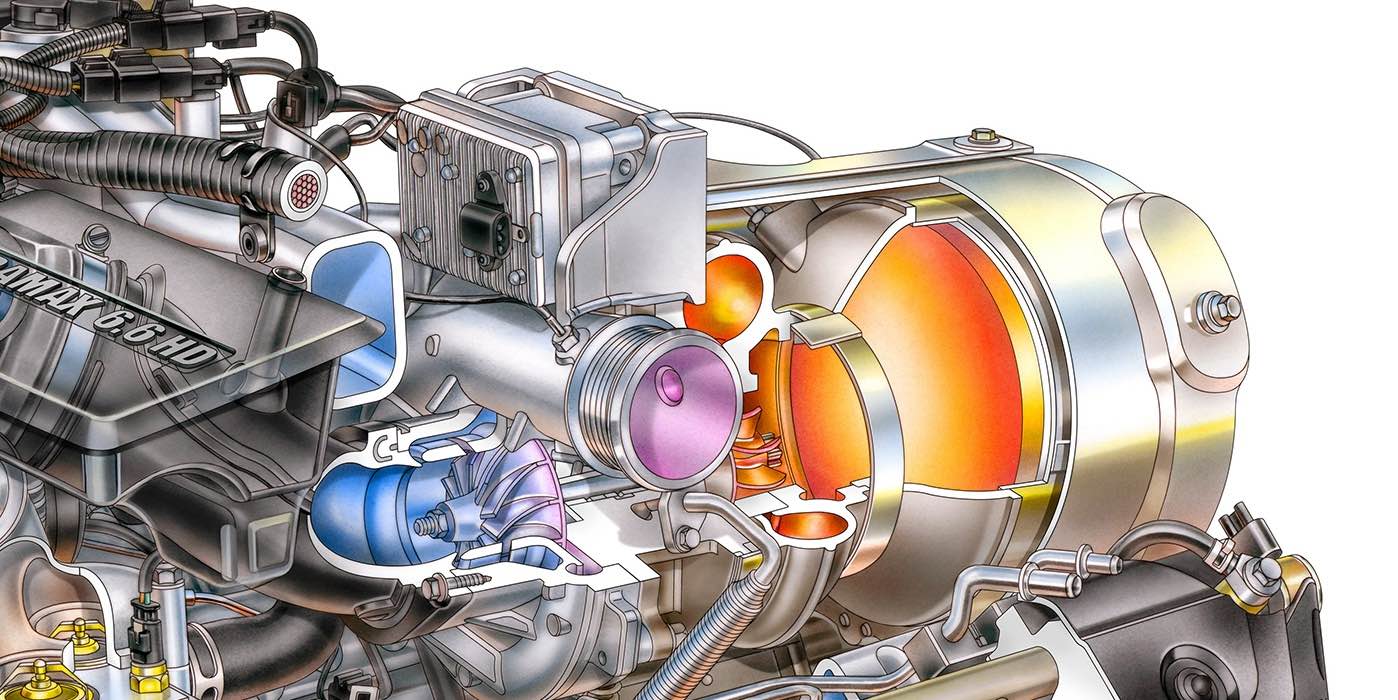

The 2012 model year marked the first year electronic stability control (ESC) became a standard feature in vehicles. The government calculated that it would cost less than $400 per vehicle.

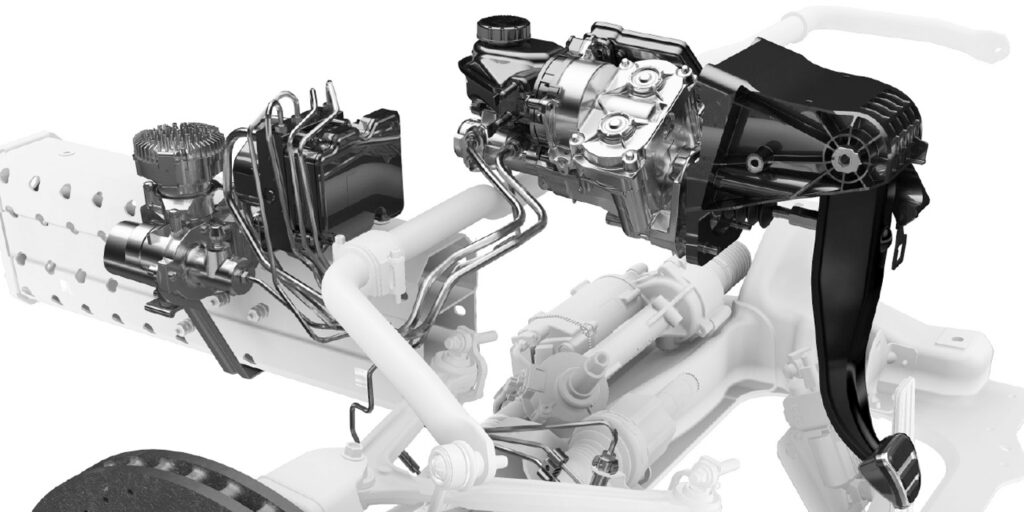

The reason for the extra cost was the additional sensors to measure the yaw and lateral acceleration. With changes to the software in the ABS module, stability control could be applied to most cars and trucks.

Diagnosing false activation with ABS and stability control systems has become more common as these vehicles have aged. False activation incidents involve the ABS modulator taking over braking or intervening to restore vehicle stability. The customer may feel feedback in the brake pedal like a pulsation or sudden drop. Some may also experience a drop in power or the vehicle may suddenly pull in one direction. In some cases, the vehicle suddenly under-steers or over-steers.

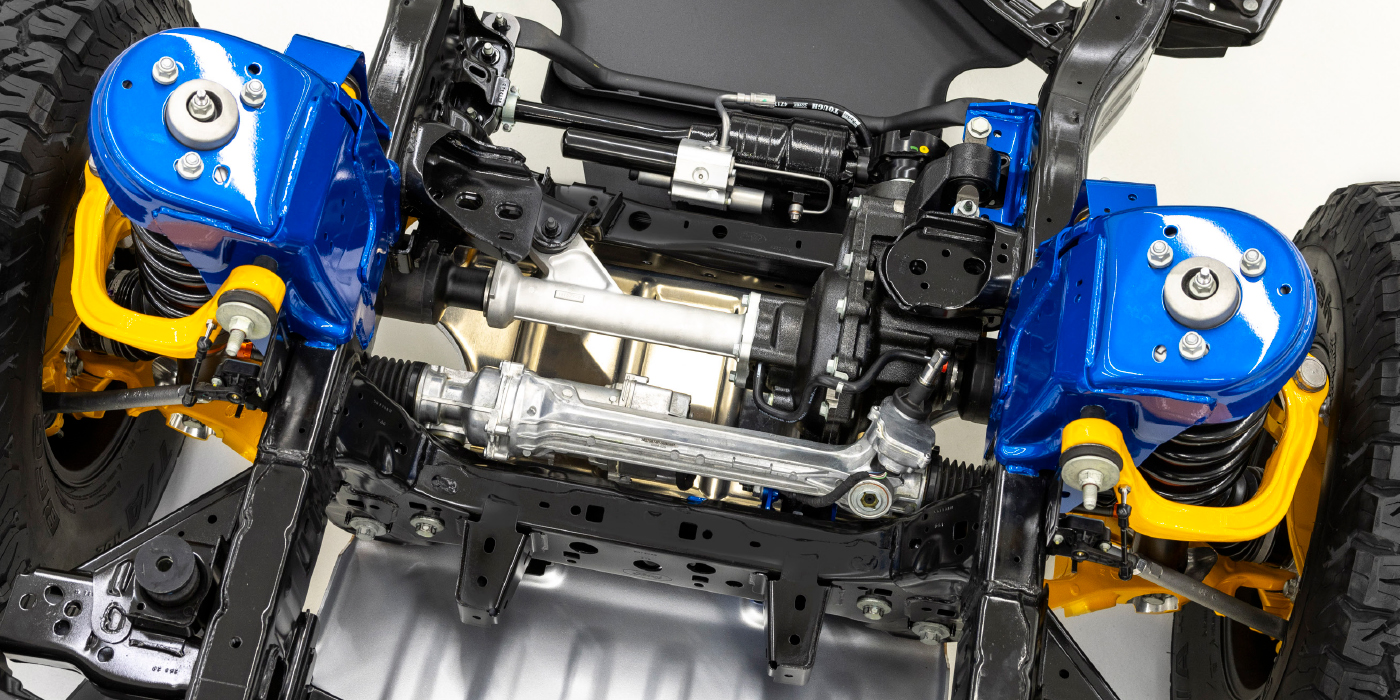

WHEEL SPEED SENSOR PROBLEMS

The most common complaint on older vehicles is ABS activation at speeds between 3-15 mph. This problem usually starts with the wheel speed sensors. A weak signal from a sensor is interpreted as a locked wheel, which triggers the computer to activate the ABS system and release brake pressure in an attempt to unlock the wheel. The driver might experience a longer-than-normal stop.

On these older systems with passive sensors, the cure for false activation is to clean the tip of the wheel speed sensor, inspect the tone ring and adjust the air gap. This typically fixes the problem.

New magneto-resistive sensors or “active” wheel speed sensors are not prone to issues of metal accumulation on the tip of the sensor. But, debris can build up on the magnets embedded in the reluctor ring in the outer seal of some sensor. This can take a long time to accumulate.

False activations are still a problem with active sensors, but more advanced modules are able to determine if a wheel is locked or if there is a wheel speed sensor problem. Instead of activating the ABS module and causing long stops, the system will deactivate and the ABS warning light will turn on.

ESC FALSE-ACTIVATIONS

The next false-activation scenario involves the ESC system. The source of the problem can be more than one sensor and can even be traced to alignment angles. The customer may not notice an issue until there is a mechanical problem with the brakes. In these cases, you may notice that one wheel is covered in brake dust. Some customers may complain the ESC activates on slower corners or on highway off ramps.

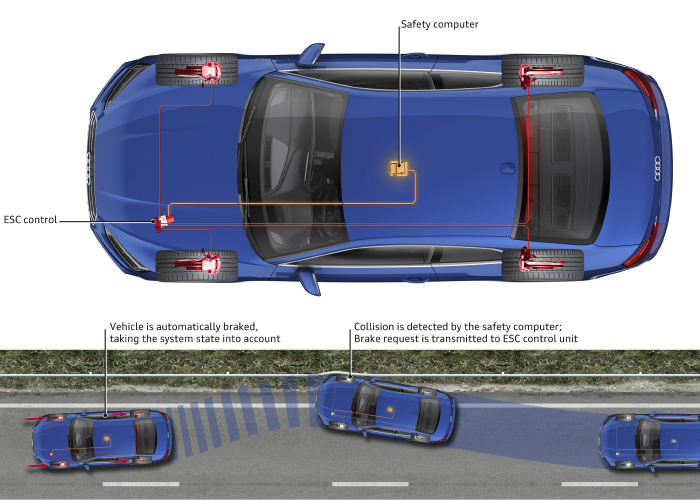

The most important sensor is the steering angle sensor (SAS), which measures steering angle, steering wheel speed and torque applied by the driver. This input tells the ESC system what the driver wants to do. The other sensors tell the ESC system what the vehicle is actually doing.

Let’s examine what happens during an understeer condition where the wheel turns, but the vehicle continues to travel in a straight line. The driver will continue to increase the steering angle, but the lack of traction keeps the vehicle going straight.

The ESC computer sees the understeer event via the sensors long before the driver realizes it. The ESC computer also sees that the driver’s steering angle is greater than the actual path measured by the yaw and lateral accelerometers.

The ESC system intervenes to try to make the vehicle turn. The first action might be to close the throttle to transfer weight to the front so the tires can gain traction. The next action might be to increase braking force on the inside front and/or outside rear tire to try to get the vehicle to rotate. All this time, the sensors are monitoring what the driver is doing and the effectiveness of the correction. This happens in nanoseconds.

Let’s say a steering position sensor is giving a false reading of an extra 50° when the car is traveling in a straight line. The ESC might perform a correction by activating the brakes in order to get the steering angle to match what the other sensors are seeing.

The other possibility is the extra 50° on an off ramp may trigger the ESC system because it is interpreting the signals as an understeer condition.

Another false activation scenario can be caused by an excessive thrust angle. The thrust angle is an imaginary line drawn perpendicular to the rear axle’s centerline. It compares the direction that the rear axle is aimed with the centerline of the vehicle. Excessive thrust angle can cause the vehicle to go down the road at an angle with the steering wheel turned to one side.

The ESC system can experience the effects of an excessive thrust angle, but it can’t see the thrust angle. The yaw sensor shows that the vehicle is not traveling in a straight line, and the accelerometers and the steering angle indicate that the driver might be trying to make a correction. The accelerometers tell the system that nothing is happening.

The ESC system might read this as the rear end starting to step out, which could be interpreted as an oversteer. The ESC system might try to correct the condition by pulsing the inside rear brake.

DIAGNOSTIC STRATEGIES

- First, interview the customer and find out when and where the problem occurs. Ask a lot of questions.

- Second, inspect the brakes for uneven wear. Compare the thickness of the pads on both sides of the axles. Also look for a single wheel covered in brake dust.

- Third, with a scan tool, observe the sensor readings for the steering angle, accelerometers and yaw sensors. Calibration procedures with a scan tool can also solve many problems.

Lastly, information is key. TSBs and service information are vital to resolving certain problems. Since these systems operate on high-speed proprietary or CAN serial data buses, the integrity of the wiring harness is critical for operation.