You may have noticed that more and more last-mile delivery vehicles are going electric. If your shop services a fleet that has gone electric, there are just as many service opportunities as internal combustion vehicles. With fleet EVs, periodic inspection and maintenance are even more important for fleet owners to get the maximum value out of their fleet.

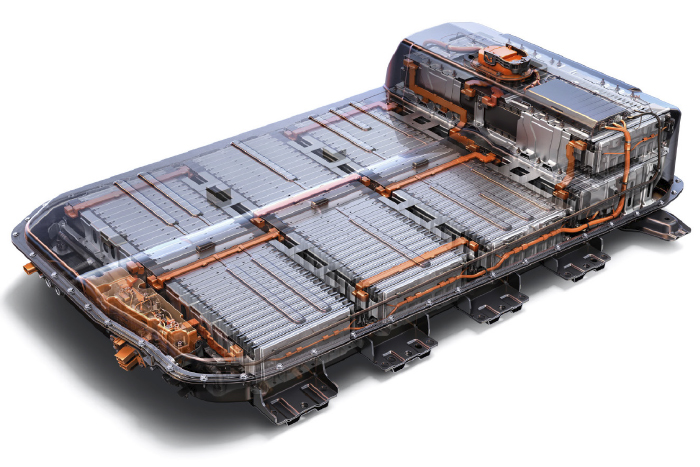

Batteries

Almost every EV has a 12-volt battery to power many systems on the vehicle, like the ABS, lighting and power steering. These are typically AGM batteries in conventional sizes. The high-voltage battery charges these batteries. Like an internal combustion-powered vehicle, they have a limited number of cycles before they lose the ability to take a charge.

The new opportunity is the high-voltage battery. As an EV last-mile vehicle ages, the high-voltage batteries can become unbalanced and will need to be replaced. With fleet vehicles, some operators will push the batteries to the limit with more charge and discharge cycles than a privately-owned EV. This will cause degradation of the charge capacity to be accelerated.

Cooling Systems

Battery packs, inverters and motors need to be cooled and heated. Most coolants are non-conductive glycol-based that need regular replacement. Also, EV cooling systems have electric pumps and valves that can fail. Cooling hoses will also need replacement in the future.

Tires

Electric fleet vehicles can be hard on tires due to the instant torque of the electric motor. Also, the weight of the vehicle’s battery pack adds extra weight that can wear tires faster. The tires for some electric vehicles are engineered for specific performance characteristics. The first consideration is load. A tire might be the correct size for an EV, but it might not have the same load and speed ratings as the original.

The other consideration is friction and rolling resistance. Some tire manufacturers use compound and tread designs that minimize rolling resistance to increase the range of the vehicle. Some replacement tires could have better handling at the expense of rolling resistance.

TPMS

Electric vehicles must be equipped with a tire pressure monitoring system. The majority of these direct systems are the same as those on conventional vehicles. There is an opportunity for replacement sensors and service kits. The operation of the TPMS system matters more to EVs because most do not have a spare tire due to weight and range.

Suspension

EVs travel on the same roads as conventional vehicles. They are not immune to curbs and potholes. Replacement control arms, struts and other parts are available from your suppliers. Many fleet electric vehicles use a platform identical to internal combustion-powered vehicles.

Steering

Since there is no engine to drive a hydraulic power steering pump, electric power steering is mandatory for EVs. Electric power steering comes in three styles. These units typically use the 12-volt architecture of the vehicle. The opportunity for shops is rack replacement.

Wheel Bearings

Electric vehicles often have the same wheel bearings as other fleet vehicles. Just like the suspension, wheel bearings can be damaged by potholes and curbs. And, these bearings can be under increased loads due to the weight of the battery pack.

Brakes

Electric vehicles recharge high-voltage batteries with regenerative braking under most conditions. With regenerative braking, the motor turns kinetic energy into electrical energy. Regenerative braking can’t be used all the time, though. When the motor can’t create enough drag at low speeds to bring the vehicle to a smooth stop, the hydraulic brakes start working. During panic or hard stops, hydraulic brakes are used.

The opportunity for shops is still the same for electric fleet vehicles when it comes to brakes. These vehicles still need brake pads, rotors and calipers. Due to the regenerative braking system, the hydraulic system needs periodic fluid maintenance to protect pedal stroke simulators and more advanced ABS hydraulic control units.

Alignment

All EVs need chassis alignment. The benefits of an alignment for EVs are two-fold. An alignment increases the life of expensive low-rolling resistance tires. Also, if the camber, caster and toe are within specification, it will extend the range.

Diagnostics

All vehicles require diagnostics to find the cause of a customer complaint or drivability issue. While you might not have to diagnose misfires and fuel trim problems with EVs, you will have to diagnose battery and power problems for EVs in the future.

Reprogramming, Calibration and Reflashing

Good news! All the skills you learned about J2534 relearns also apply to EVs! If a battery pack, steering rack or other module is replaced, you must program the module. Also, EVs tend to have more updates as the engineers refine the software to get more range.