Diagnosing a suspension noise complaint can be more complicated than curing a misfire trouble code. Instead of a scan tool, your diagnostics tools are your eyes and ears, but they can be augmented.

Like an engine, you are dealing with multiple systems that affect each other. If one suspension part is out of specification, it can cause noise or vibration in another.

The first time you will use your ears is to listen to the customer. If you are writing up the customer, no detail is too small for a technician. If there is a good description of the noise, chances are better that .you can then duplicate the noise. If you can’t replicate the noise, you can’t fix it. The next step is to perform an inspection.

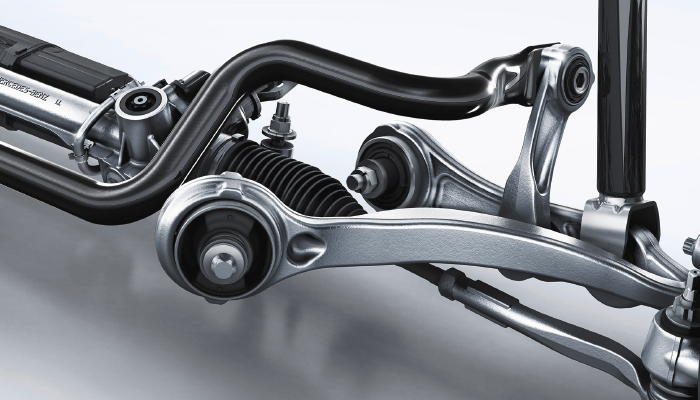

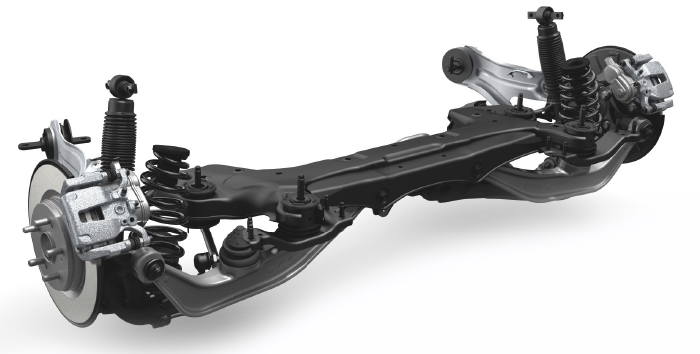

Chassis and suspension design has evolved. Struts have replaced a lot of upper control arms. Also, many suspensions are made of a mixture of aluminum, stamped and cast iron components. The best advice is to look at the TSBs for the vehicle. If you can’t find a bulletin related to your problem, you might find a procedure to isolate a noise problem.

Steering Column

The modern steering column will have one or two universal joints and other elements that can cause noise. The most common area for noise on higher mileage vehicles is the bushings and bearings around the shaft and the mounts that hold the column to the dash.

The bushings, bearings and mounting points can be damaged by drivers that use the steering wheel to get in and out of the vehicle. The extra force on the column in directions that were not designed for can break parts inside the column.

The clock string for the steering wheel controls and airbag can be damaged by drivers using the wheel as a grab rail. The spring that allows the ribbon cable to extend and retract can break or lose tension.

Noise Characteristics: This will be a rattle that changes as the wheel is turned. In extreme cases, play can develop in the universal joints and shaft. This can cause noise as the wheel is turned.

Diagnostic and Isolation Methods: Try turning the steering wheel with the engine off. The steering wheel should have zero play. Try moving the wheel in and out and press on the sides.

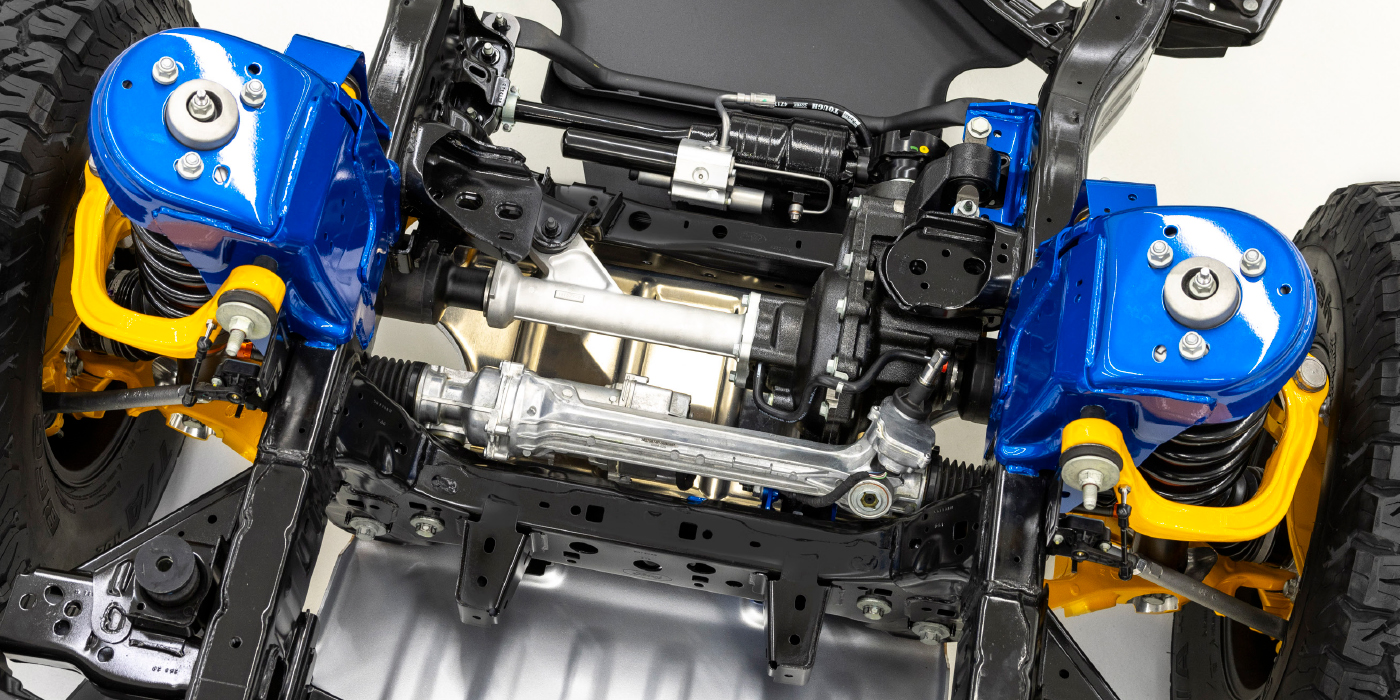

Upper Strut Mounts

The upper strut mount acts as an upper control arm for some suspensions. These mounts are made from steel, rubber and bearings. The rubber can separate from the metal components and cause noise. Also, the bearings can fail and cause memory steer, rough spots and noise. Most upper strut mounts have a thin layer of rubber between the mount and strut tower. The relentless pounding from the suspension can degrade the rubber. When it is no longer present or compacted, vibration and noise are transmitted directly through the body.

Noise Characteristics: A worn upper strut mount will cause various knocking noises that match bumps in the road. The noise can also occur and change while turning. Knocking or popping noises can also occur when the steering is turned.

Diagnostic and Isolation Methods: Visual inspection is the first step. Look for separation between the rubber and metal. Also, the rubber should not be cracked. The strut mount will move as you push down on the fender; this is normal. With the suspension unloaded, move the wheels from lock to lock. This can isolate problems with the upper strut mount’s bearings. Any roughness or popping can indicate a problem.

Spring Isolators

Some springs do not directly rest on the perches. Between the two components might be a rubber isolator on the perches or wrapped around the springs. These can prevent noise and dampen vibration. Isolators can wear overtime or fall off the perch or spring.

Noise Characteristics: Low pitched noise can occur under certain conditions. The noise might occur or change as the steering angle is altered. If the insulator is missing, the spring’s compression can cause a knocking noise as the coils make contact. On a non-steering axle, it will cause a rattle as the road surface changes.

Diagnostic and Isolation Methods: Visually inspect the mount and replace if the strut or spring is replaced.

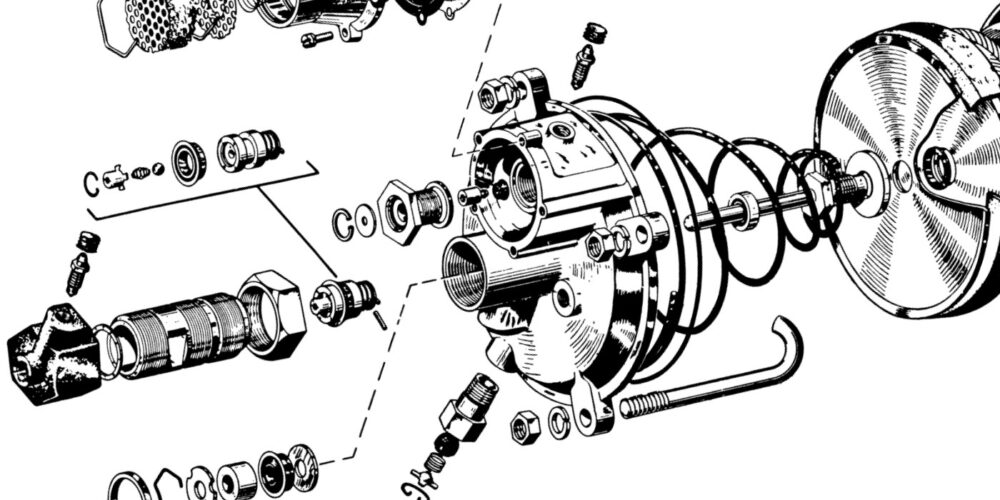

Ball Joints

Worn ball joints are not a noise problem, worn ball joints are a safety problem. By the time a ball joint starts making noise, it has probably exceeded the verticle movement specifications. Most modern sealed ball joints have a .000” specification. Even those with a .004” or .002” specification are difficult to detect.

Noise Characteristics: Knocking noise when the steering and suspension moves.

Diagnostic and Isolation Methods: Measure the verticle movement with a dial indicator.

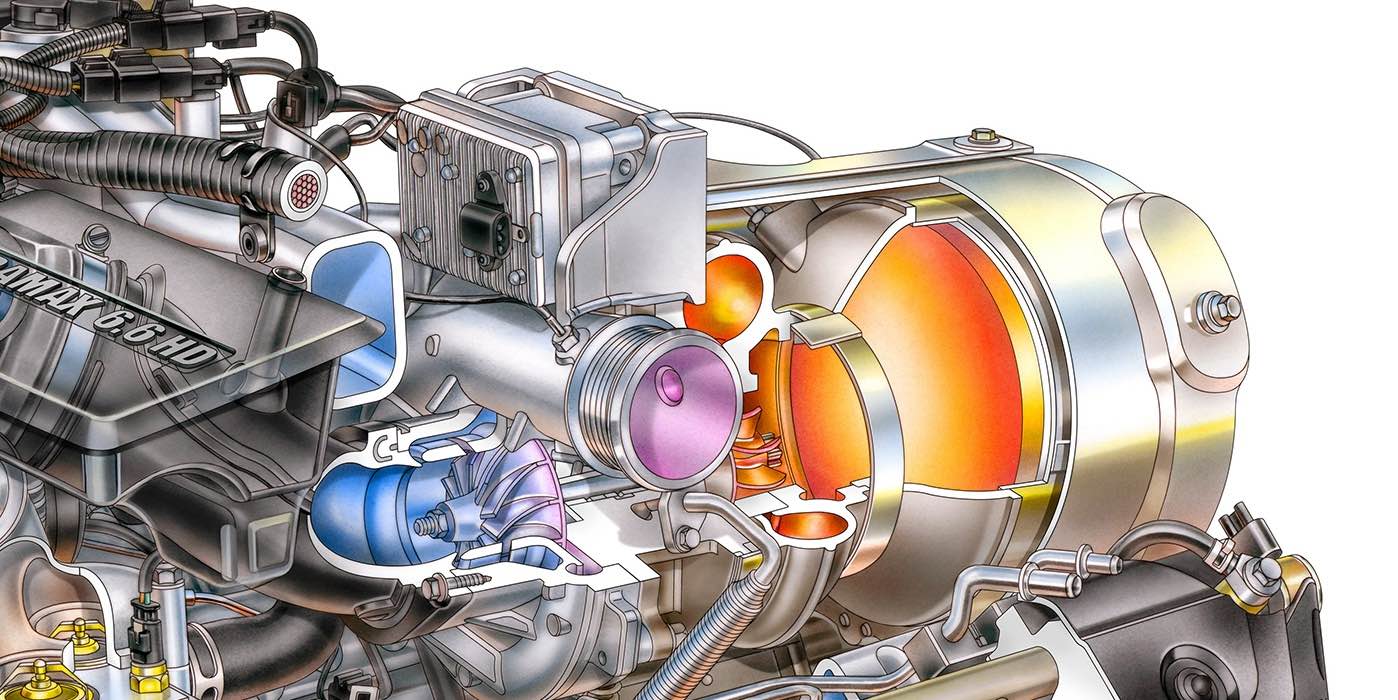

Rack and Power Steering

No matter if the vehicle has electric or hydraulic power steering, inspect the bolts and bushings that hold the rack to the body or chassis. If the mounts are worn, it can cause many types of noise, depending on how the unit is mounted to the vehicle.

If the steering is hydraulic, look at the lines. If a line comes in contact with the body, it can transfer noise from the rack and pump into the passenger cabin.

Due to the nature of the brushless motors used by electric power steering units that are attached to the column or rack, they are typically very quiet. But, these items can wear and cause noise. If you do suspect an electric power steering unit is causing noise, look at the TSBs and service information to confirm if the condition is abnormal or normal.

Noise Characteristics: Noise and vibration depend on power assist type and configuration.

Diagnostics and Isolation Methods: Visual inspection of the rack, pump and lines is the first step. Make sure the power steering fluid is at the correct level and free of bubbles. On electric power steering systems, a scan tool can be your best friend. Many scan tools have test modes that can turn off the power assist so you can isolate the mechanical and electrical parts of the steering system.

Bushings

Modern suspension bushings act like a progressive spring. As the bushing is loaded in different directions, the first few millimeters of movement might occur with very little effort. As the load increases, the bushing will become stiffer. This can insulate the suspension from the chassis and cabin. Most noises occur when the bushing is damaged and the inner part of the bushing comes in contact with the outer shell.

Noise Characteristics:The noise will typically be a knocking noise that occurs when the suspension moves or the vehicle changes direction.

Diagnostic and Isolation Methods: Inspect the bushing for separation of the metal and rubber. Also, look at the rubber for cracks. Using a set of “Chassis Ears” microphones can help to isolate the damaged bushing.

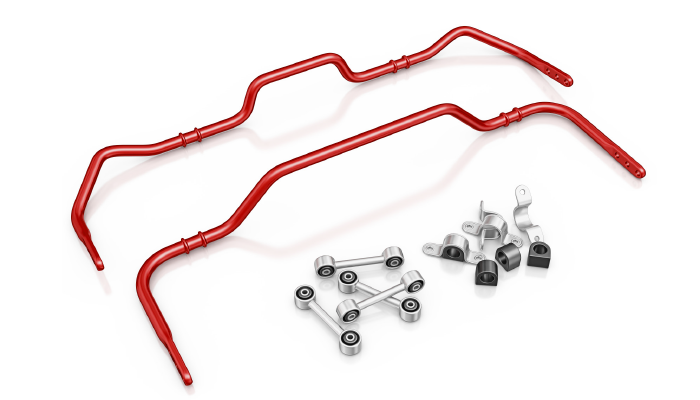

Anti-Roll or Sway Bar

The sway bar acts as a third spring that controls the movement of the body of the vehicle. A sway bar has multiple areas that can cause noise. The bars are connected to either the control arms or the struts. The links connecting the bar to the suspension can wear out. Older vehicles utilize a stack of rubber bushings and washers around a shaft. Newer vehicles are more likely to use links with ball and socket joints.

The links can separate from the bar or control arms. When this happens, the links can cause noise when the suspension moves. The bushings holding the bar can wear and cause noise as the bar is loaded.

Noise Characteristics: Knocking noise coming from the lower control arm area. When some links are separated, it will not cause any noise at all. If the sway bar is disconnected, the body of the vehicle will have excessive roll during cornering.

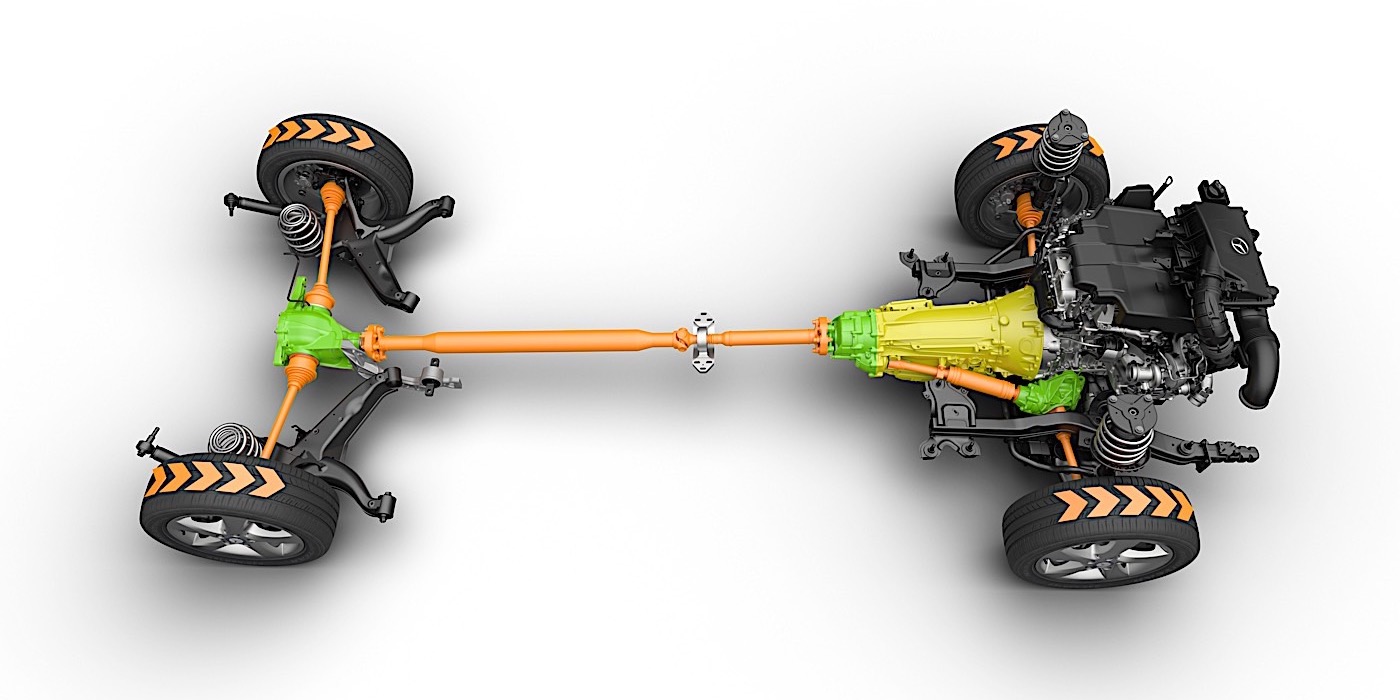

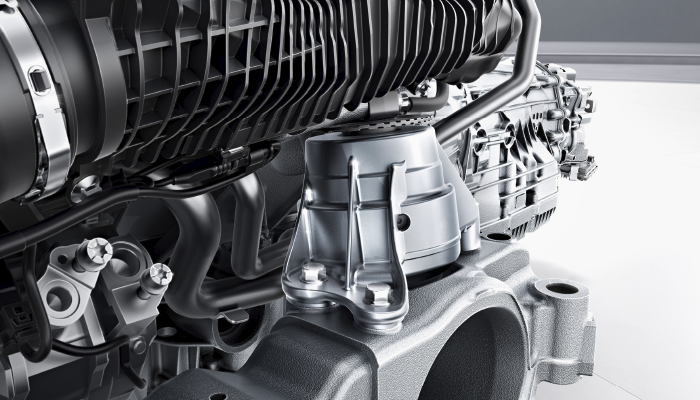

Motor and Transmission Mounts

While the motor and transmission do not support the suspension, the application of power to the drivetrain can cause noise problems that mimic a suspension problem like a worn control arm bushing or upper strut mount.

Noise Characteristics: Knocking noise that can come from high or low in the engine bay. Noise will occur or change when the brakes or gas is applied.

Diagnostics and Isolation Methods: For motor mounts, you can shift the transmission between drive and reverse with the brakes applied and look for excessive movement of the engine.