Shocks, struts and springs are the connection between sprung and un-sprung parts of the vehicle. The design is simple, with just a piston traveling in a cylinder full of oil to control the travel of the suspension and movement of the body during weight transfer. If the engineer gets it right, the valves in the piston and base of the shock or strut will be able to keep the tires in contact with the road and the body level under a wide variety of conditions. Unfortunately, the suspension can be damaged, and the shocks and struts will degrade. This can lead to handling issues and noise problems.

In theory, diagnosing a noise problem with the suspension requires starting at the attachment points to the uni-body, subframe or frame. The inspection ends when you reach the tires. The shocks, struts and springs can cause noise problems with every component in between.

Changing Suspensions

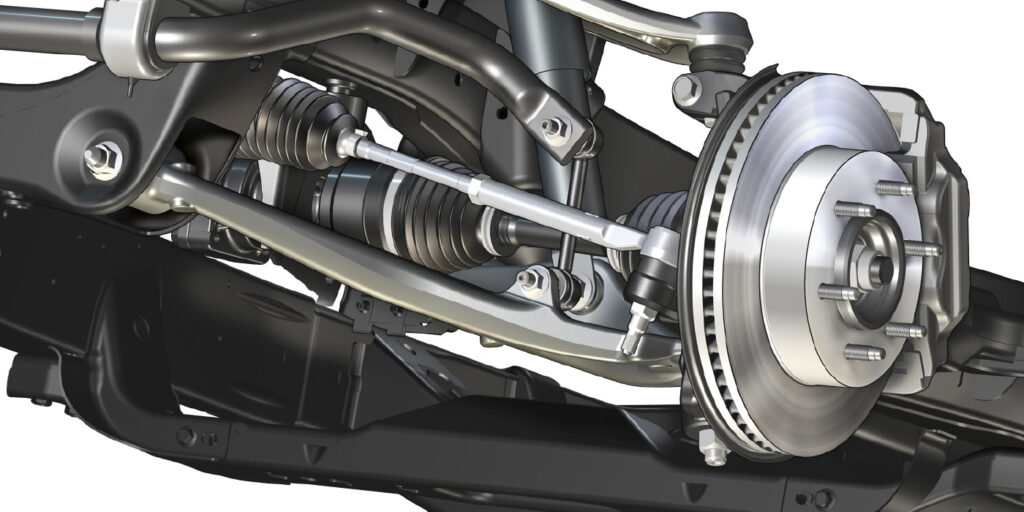

Suspensions have changed in the past 25 years. Some front suspensions may have two-piece lower or upper control arms made of aluminum. Rear independent suspensions have at least three links. How the suspension is attached to a subframe or unibody can change how the driver hears or experiences a noise.

Tolerances related to the suspension components and ride control have tightened. Ball and socket joints have play tolerances that are almost too small to measure. For some suspension bushings, the inspection procedure involves counting the cracks in the rubber.

Service information and TSBs can help you identify vehicle and platform-specific noise problems. The service information also contains inspection procedures. While almost every OEM has a TSB related to what they will warranty for a leaking strut, many include information to silence common noise problems related to the ride control or suspension.

Some TSBs can include fixes as simple as lubricating the jounce bumper or tightening subframe bolts. One of the more interesting TSBs on ride control noise was issued by Acura for the 2014-2015 RLX (14040). It revealed that some rattle and clunk complaints were being caused by an internal valve characteristic of the original strut.

With all vehicles, it is difficult to classify a noise with a single word. A knock to one person might be a clunk to another person. Also, a worn upper strut mount may have a different sound on a crossover than a car or pickup. With differences in vocabulary, documenting when and where the noise occurs is just as important as what it sounds like.

Worn Out and Noisy

If a shock or strut is worn, it can increase the possibility of noise from the suspension. Why is that? A worn shock or strut can’t control the movement of suspension and wheel and tire assembly. Movements of the suspension use more travel and can be more forceful. Also, the chances of the suspension bottoming out can increase.

Many late-model vehicles have bushings that help control the suspension angles during braking, acceleration and cornering. These bushings are molded with reliefs and voids that allow for movement in a specific direction. If the shocks and struts can’t control the suspension movement, it can limit the life of the bushing.

Sway bar links take a beating if the ride control components are worn. On many cars and trucks, the sway bar connects to a tab on the strut. These links have ball and socket joints at the ends. Typically, they have a metal ball with a plastic insert. When the joints are worn, they can cause noise that can be easily misdiagnosed. If you are dealing with a high-mileage vehicle, consider replacing the links along with the struts.

The upper strut mount and bearing plate serve as both the upper spring support and the steering pivot. The bearings in the plate are sealed assemblies and cannot be lubricated. So, if the bearing plate is rusted, loose, worn, noisy, binding or damaged, it has to be replaced. The rubber materials that make contact with the strut towers and unibody can degrade due to the harsh environment.

Noise Tools

The best tool on the market is you. As a human being, you can hear and feel conditions in the ride control components and suspension. And, your eyes are essential to making the final call when it comes to making the definitive diagnosis.

Chassis ears are another tool that can help you isolate noise or vibration. They are microphones that work like a doctor’s stethoscope and have clamps that attach to components.

You can attach it to the vehicle to listen to a noise problem. The wireless units can be used on the lift or during a test drive.

Another option is to use a three-axis accelerometer and microphones that connect to a scope. This is what some OEMs are requiring dealerships to use to find and diagnose noise problems before they write the warranty check.

The three-axis accelerometer measures vibration and can be attached to the driver’s seat or near the suspension. This NVH tool can connect to the vehicle’s OBDII port to capture the vehicle’s speed and engine RPM. The scope connects to a PC and can detect and classify a vibration or noise problem. This is what I would call an “I’m not crazy” tool to verify a customer’s complaint. The tool has other advantages in analyzing vibration problems that occur at specific speeds.

The Test Drive

The priority for any test drive is to duplicate the customer’s complaint. The complaint needs to be adequately documented when the customer drops off the vehicle. If the service order has the line to “check for noise…”, chances are the problem will not be reproduced. Taking time to interview the driver will make for a faster repair and happier customer. If you are recording the complaint, let the driver speak. Don’t interrupt them with a diagnosis.

If the problem can be reproduced, the test drive should not stop there. The test drive should include a route to test the ride control. When correctly performed, you can evaluate the condition of the shocks and struts. But, you have to understand how the shocks and struts control the movement of the suspension.

The typical shock or strut has two types of dampening forces: high- and low-frequency. High-frequency dampening is the rapid movement of the suspension. On the test drive, this type of dampening is required to deal with sudden bumps and dips. Inside the shock or strut, the rapid movement causes a valve to open quickly during compression and rebound. This allows the tire to stay in contact with the road and prevents the motion from being transmitted to the body and unsettling the vehicle.

Too much dampening and the ride will be harsh because the energy can’t be absorbed by the spring. Too little of a dampening force will cause the inertia of the suspension to fully act on the spring, causing it to continue to travel. This will eventually cause the tire to lose contact with the road.

On the flip side is high-frequency rebound. On the test drive, this can be tested on concrete seams and driveway turn-ins. Typically, if this is an issue, it will feel like the suspension is still reacting to a bump even after it has passed over it.

The second type of dampening is low-frequency. This is a slower movement of the piston. Low-frequency dampening controls the movement of the body on the suspension and the transfer of weight on the tires. These are the forces associated with nosedive, acceleration squat and body lean. If a shock or strut is worn or damaged, it will not be able to control suspension movement and weight transfer. This ultimately leads to an unstable vehicle. The low-frequency dampening can be tested with braking and acceleration.

Other things you can try on a test drive can help to isolate specific components. Try performing a figure eight at close to full lock to evaluate the upper strut mounts. A collapsed upper strut mount or a broken spring will cause binding and contact between the spring and tire on some vehicles. Swerving side-to-side can help to isolate the sway bars and links.

The length of the test drive matters. Almost every modern shock or strut is gas charged. A chamber or bladder of nitrogen gas keeps the oil inside the dampener under pressure to prevent foaming or aeration of the oil in the shock caused by cavitation as the oil passes through the valving. If you notice significant changes in the dampening levels during a 15-minute test drive, chances are the gas charge has leaked out of the units. In some cases, the customer may say noise may occur after driving for a specific length of time. The source could be a shock or strut with a ruptured gas chamber or bladder.

The biggest part of the equation is the customer. A noise to a customer could be interpreted that their vehicle is unsafe or could leave them stranded by the side of the road. With customers holding onto vehicles longer, solving the noise problem is the first priority. But, investing in ride control can eliminate noise problems down the road.