Mercedes-Benz 4MATIC all-wheel drive (AWD) systems have been around for a while now, and it’s safe to say that they’ve worked out a lot of the kinks by now. That’s not to say that these systems are impervious to problems, because we all know that any mechanical system will eventually break down, wear out or fail.

History

4MATIC, as we know it, came on the market with the 1998 model year on the E-Class and M-Class SUV. In the past 20+ years, 4MATIC has become an option on every vehicle Mercedes-Benz sells. Those of you who reside south of the rust belt won’t necessarily see many 4MATIC vehicles coming through your shop, except of course for certain high-horsepower AMG models which come with AWD as standard. But, for those of us who live north of the rust belt, 4MATIC is almost all we’ll ever see in the shop.

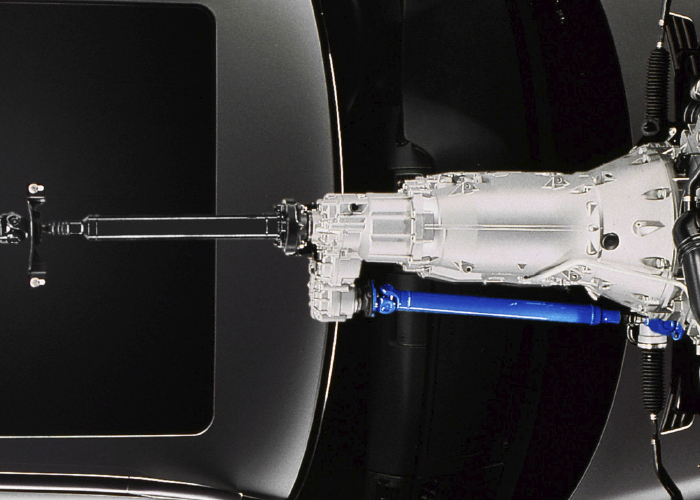

You see, 4MATIC is very much in its element in the snow. I can attest to this myself. I had a 1998 E320 4MATIC wagon, and I absolutely loved that car in the winter. With a proper set of snow tires it was all but unstoppable, and I took a great bit of satisfaction from pulling 4WD trucks out of the ditch after a heavy snowfall. The 4MATIC in my E320 (Figure 1) was a bit more rudimentary than what you will find in a modern-day Mercedes. The transfer case was larger, and the driveshaft took up quite a bit of space next to the engine. This meant that the floor pan needed to be different on any 4MATIC vehicles.

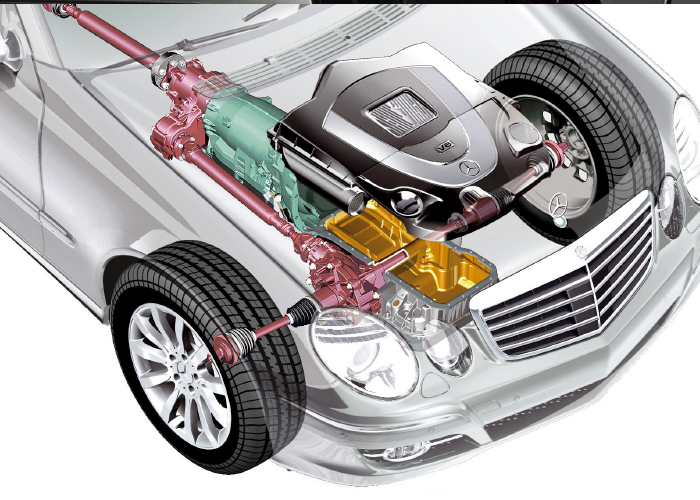

Personally, I find the front differential setup to be the most interesting part of the whole system. 4MATIC vehicles use a specific upper oil sump which has a pass-through for a CV extension built into the casting (Figure 2). The LH front axle shaft then attaches to this extension. All of this helps to keep the entire package compact, and as low as possible, thereby preserving the center of gravity.

Modern 4MATIC

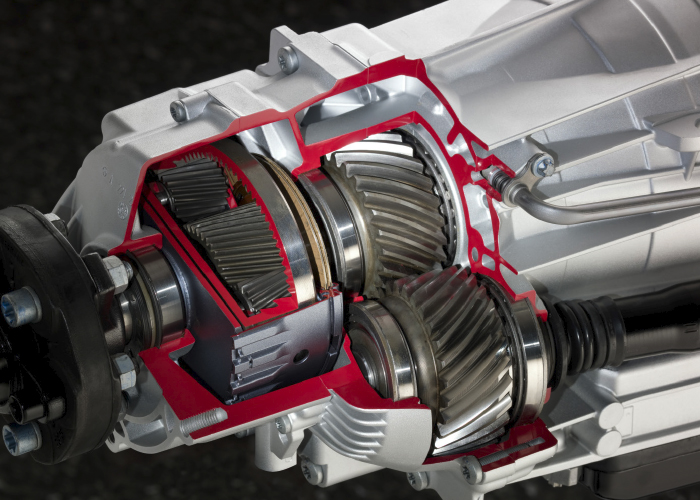

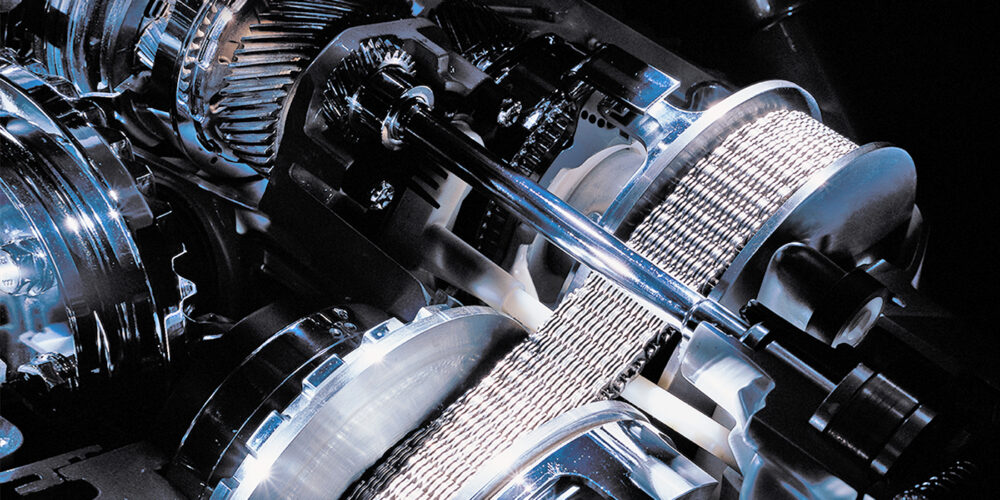

4MATIC is constantly evolving. In the past two decades, there has been a shift in how the power is split, packaged and where the differentials are located. The current generation of the 4MATIC system is all but bulletproof mechanically speaking. The cutaway in Figure 3 shows the simplicity of the helical spur gears to transfer engine torque to the front driveshaft. It adds only 23-32 pounds (50-70 kilograms) of extra weight, depending on the model.

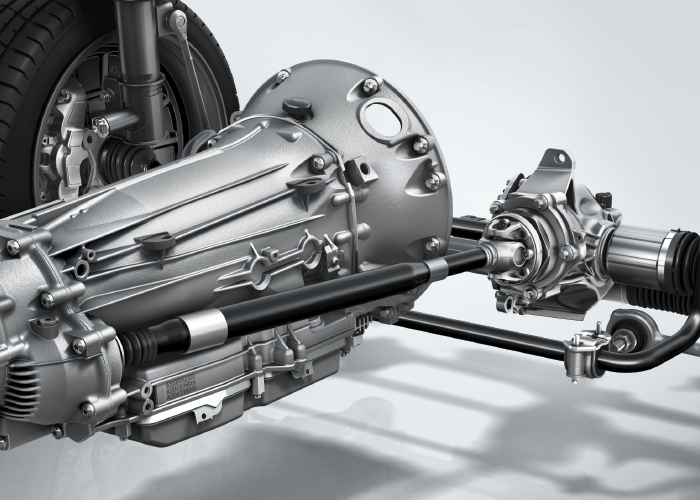

The newest generation of 4MATIC also features a much more compact design which takes up less space (Figure 4). This means that no modifications to the floor pan are needed, and the front-passenger footwell is not impacted. This new design isn’t just more compact, it’s more fuel efficient, too. This is thanks in part to the removal of the gear stage for the transfer case’s power take-off (PTO), as well as an optimized oiling system.

ESP and ETS

All 4MATIC systems use an Electronic Traction System (ETS) and an Electronic Stability Program (ESP). These systems work in tandem with the ABS modulator and the brakes to control traction to individual tires. The hydraulic control module on a 4MATIC has at least 12 valves. With these control channels, the ETS can make a 4MATIC vehicle with open differentials perform like it has limited-slip or locking differentials. Passive or open differentials transfer the power to the wheel(s) that is spinning the fastest, or the wheel that is on the ring-gear side of the differential.

The ETS system uses the brake calipers to apply pressure to whichever wheel is spinning, and send power to the opposite side of the differential. This can evenly distribute the power to the rear or front axles under a variety of conditions.

If the car or truck is accelerating hard from a stop, the ETS will apply the brakes independently to prevent slipping. Even if the driver turns off the stability control, the brakes will manage the rear axle so it performs like a limited-slip differential. If the vehicle is in snow or mud, it can control the traction with the brakes, so the differential acts like it is locked. The corrections are very fast pulsations of the brakes which are undetectable by the driver. The same system is used to control torque steer on the CLA and other Mercedes-Benz front-wheel-drive platforms.

The ETS system needs the foundation brake system to be in proper working order to function. This means that the pads and rotors must be able to produce enough friction to carry out the 4MATIC corrections. Issues with seized calipers can result in less-than-optimal corrections.

Fluid Leaks & Wear

Any leaks from the transmission, transfer case or differential should be taken seriously. Damage can occur if the fluid drops to a critical level. The most common leaks can be found around the driveshaft and axle seals.

Sometimes, there will be oil leakage at the seam between the automatic transmission and the transfer case; it can occur around the entire seam. If droplets can be seen, seal the areas with black sealant in the vicinity of the propeller shaft to the front axle transmission. If the problem is a “sweating” leak, sealing must not be carried out, as this is a normal phenomenon inherent in the design of oil-filled systems. If there are any leaks in the differential transfer case, check the vents and breathers. The seals can leak and fail if the case is over pressurized.

When it comes to fluids, the 4MATIC transfer case uses automatic transmission fluid that meets Mercedes-Benz standards. The same is true for differentials that use 75w-90 hypoid gear lubricant. The standards for the fluids for the entire vehicle can be found at bevo.mercedes-benz.com. They even have an app that can be downloaded from the Apple and Google app stores.

Service Considerations

Be sure to visually inspect the flex coupler(s), checking for any signs of cracks and/or loose bolts. These issues could surely cause a vibration or noise concern, and if left alone long enough the results can be disastrous.

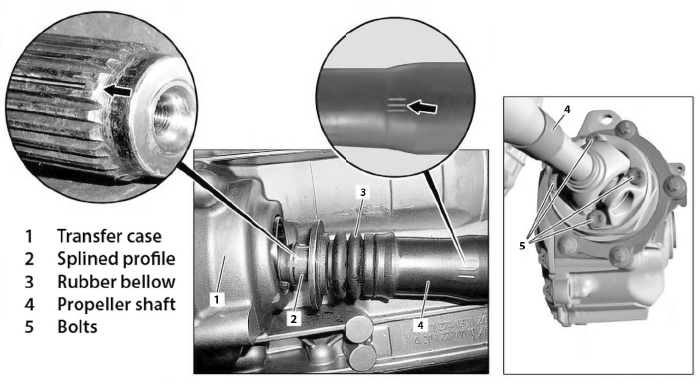

Whenever working on a modern 4MATIC system, it’s important to always reference the OEM service information. Let’s look at the W213 chassis E-Class as an example. The front propeller shaft features a U-joint on the front differential side, and splines on the transfer case end. These splines can only be installed one way, and there should be a marking on the propeller shaft which will line up with the matching spline on the transfer case (Figure 5). Be sure to mark the U-joint end with paint before disassembly so you can match the factory installation position.