Bulletin: T-SB-0015-13

Models: 2009-’13 Venza

Problem: Some 2009-’13 Venza vehicles may exhibit a “pop” noise from the steering column when turning the steering wheel sharply during low-speed maneuvers. Perform the repair procedure outlined in this bulletin to address this condition.

Repair Procedure

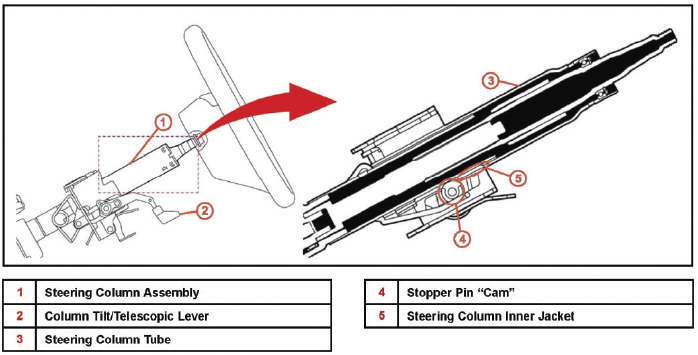

1. Confirm the condition. With the vehicle in Park and engine running, release the column tilt/telescopic lever and rotate the steering wheel from right lock to left lock several times (refer to Figure 1). With the tilt/telescopic lever released, did the steering “pop” noise go away?

– YES: This bulletin does apply. Go to step 2.

– NO: This bulletin does not apply. Refer to the applicable

Repair Manual for diagnosis.

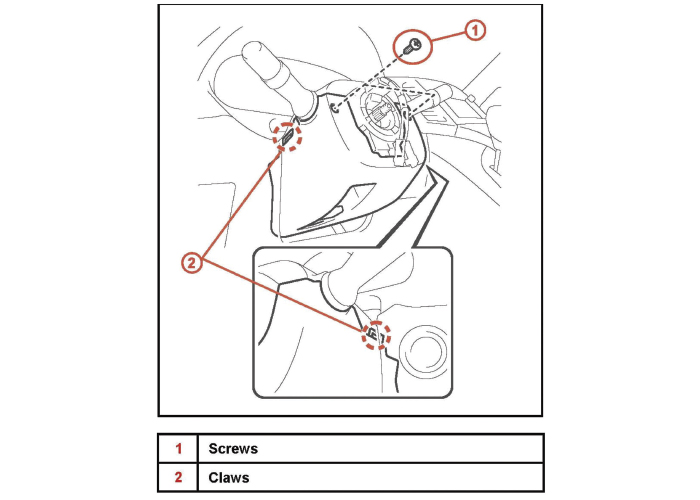

2. Remove the lower steering column cover.

a. Remove the two screws.

b. Push the right and left sides of the lower steering column cover, and disengage the two claws as shown in Figure 2.

3. With the column tilt/telescopic lever released, fully extend the column telescope toward the driver’s seat and tilt the column up to the highest tilt position.

4. Using the syringe from the grease kit, apply grease to the column inner jacket and the stopper pin cam.

Grease Amount

- Column inner jacket: 0.3-0.4 ml

- Stopper pin cam: 0.2 ml

5. Cycle the steering column telescope (extend and retract) 10 times to evenly distribute the grease.

6. Engage the column tilt/telescopic lever.

7. With the vehicle in Park and engine running, confirm that no noise is present by cycling the steering wheel from right lock to left lock several times.

a. If the noise still occurs, inspect for distribution of grease over these areas and apply additional grease, as necessary.

b. If noise is no longer present, reinstall the lower column cover.

c. Engage the two claws clips to install the lower steering column cover.

d. Install the two screws. Torque: 18 in./lbs.