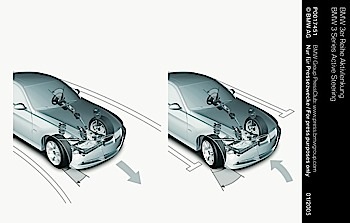

As a vehicle brakes, accelerates and corners, weight is transferred and the vehicle attitude changes.

If done in a controlled manner, braking can transfer weight effectively to the tire that needs it the most. For the most part, the suspension and tires handle the best when weight transfer is not sudden and the suspension is not compressed on the bump stops.

The transfer of weight has momentum. If a driver is making a sudden lane change and a panic stop to the right, the weight of vehicle is transferred to the left-front wheel. If that corner of the vehicle has a weak shock or strut, the suspension could rapidly compress. As a result, the right-rear tire has less weight and less traction, as does the left-rear to a lesser extent. This means that the vehicle could go from an understeer condition to a “snap” oversteer very quickly. In the worst-case scenario, if the vehicle has a high center-of-gravity like an SUV, it could roll. If the vehicle has effective shocks or struts, the weight transfer is better controlled, as is the vehicle.

The role of ride control and tires becomes even more critical on vehicles equipped with ABS, traction control and stability control systems. As in an emergency lane-change situation, the driver can now steer under panic braking. This means that weight transfer and vehicle pitch can be even more extreme.

Why Shocks Wear

The main reason why shocks wear is because they have a hard life. Even under normal conditions on a smooth road, shocks stroke an average of 1,750 times for every mile traveled.

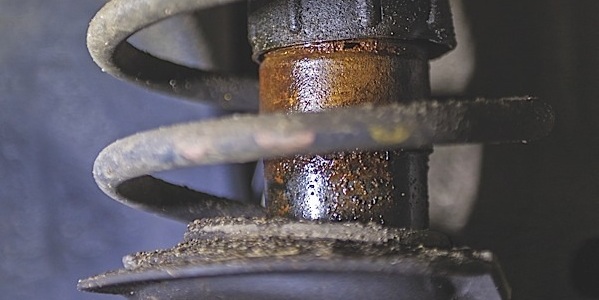

Inside the shock, a piston travels up and down a tube. Wear can occur between the piston and tube, and, over a period of time, oil will pass between the piston and tube.

If the suspension bottoms out, contact between the piston and the bottom of the tube could occur. This can damage the piston and the valving.

Also, if the shock is worn, the springs will have to work harder and could wear out sooner causing ride height and ride problems.

Shocks are filled mostly with oil. This oil can have different weights. When the oil heats up, it can affect the rate of flow through the valving as it either thins out or becomes more viscous. Some shock manufacturers also use multi-weight oils that work like motor oils. When the oil is cold, it may flow like 15-weight oil. But, as the oil heats up, it could flow like a 20-weight.

The oil can become contaminated with debris either from the outside or from internal components. Dirt can enter the shock through the gasket that seals around the rod. This is why it is critical to replace all dust boots when installing new shocks.

Mileage alone is a poor indicator of worn shocks. Some are still working reasonably well at more than 40,000 miles. And, if a customer purchases really good shocks, they might reach 70,000 miles. Regular inspection is the only way to determine a strut’s or shock’s condition.

Gas Charged

There are basically three types of shock absorber designs: mono-tube high-pressure gas, twin-tube low-pressure gas and twin-tube hydraulic (non-gas). Each of these designs has certain ride and performance characteristics that can enhance the performance of a vehicle.

The reason why gas is added to some shock absorbers and struts is to reduce foaming or aeration of the oil in the shock that is caused by cavitation as the oil passes through the valving. Over time, shocks can lose this charge of gas. If all the gas escapes, the shocks can overheat and fade.

Valves

Shocks use valves to control the flow of the oil. Valves are located either in the piston or at the base of the shock. The rate of flow will control how much force it takes to move the piston.

Valving works in both directions of compression and rebound, and, in most shocks, both are independent rates.

Valving in most replacement shocks is vehicle specific. When a vehicle is designed, the shock or strut is designed to dampen certain spring rates, work with a specific tire package and is tuned to vehicle dynamics desired by the OEM.

This is important to remember when selecting a replacement shock and strut. A replacement that is too stiff could create a ride complaint from the customer.

Conventional shocks and struts are sometimes limited by their valving. Their performance is generally a compromise between a comfortable ride and one that is more controlled.

Some shocks and struts have tapered grooves in the walls of the tube that allow the fluid to freely flow around and through the piston. The result is a smooth and comfortable ride. When the piston travels beyond the tapered grooves, fluid is directed totally through the valving in the piston. This results in a stiffer shock. Remember, this shock is height sensitive and installing this type of unit on a vehicle with an altered ride height can negate its benefits.

The newest type of shock introduced into the aftermarket can sense changes in road conditions. In these shocks, the valving can determine if the stroke is a product of small bumps in the road or large changes in the vehicle’s attitude. The ability to sense between changes in the road surface and vehicle pitch allows the shock to provide a comfortable ride, in addition, to control in panic situations.

Struts

Struts are part of the suspension and they effectively replace the upper control arm and ball joint. Struts perform two main jobs. First, struts perform a shock-damping function like shock absorbers. Internally, a strut is similar to a shock absorber. A piston is attached to the end of the piston rod and works against hydraulic fluid to control spring and suspension movement. Compared to a shock, the rod of a strut is three times the diameter.

And like shock absorbers, a strut is velocity sensitive, meaning that it is valved so that the amount of resistance can increase or decrease, depending on how fast the suspension moves.

Struts also perform a second job. Unlike shock absorbers, struts provide structural support for the vehicle’s suspension. As a result, struts affect riding comfort and handling, as well as vehicle control, braking, steering, wheel alignment and wear on other suspension components, including the tires.

Because struts are a part of the suspension, in some situations they wear differently than shocks. If the upper strut mount is binding, the force is transferred through the rod to the strut’s body. Inside the strut’s body, the rod is supported by the piston and at the top of the strut housing by a bushing or bearing. Wear can be dramatic because the strut has to do the work of the bearing. Instead of the strut bearing turning and pivoting, the piston turns in the strut housing, thereby creating wear.

Selling Extras

All struts and shocks should be replaced in sets. Replacing one or two at a time can create a balance problem that could make the vehicle unstable when braking and accelerating.

Bump stops that fit on the rod of a strut should always be transferred from the old assembly or replaced with new parts. This is cheap insurance against damaging the new unit if it bottoms out. Even if the old strut does not have one, check the parts catalog for a replacement.

Don’t forget the springs. If the springs are already worn out, they can shorten the life of the new shocks and struts you are installing. Springs also control the ride height and, ultimately, the suspension angles. Shimming a set of weak springs with spacers or inserts may take care of the sagging and bottoming problems, but it won’t restore the ride quality or spring rate. To help increase spring sales, check the ride height of the vehicles in your shop.