Andrew Markel discusses wheel speed sensors, and how they determine the turning state of a vehicle. Sponsored by BCA Bearings.

Andrew Markel discusses wheel speed sensors, and how they determine the turning state of a vehicle. Sponsored by BCA Bearings.

Replacement units are available from sources other than the dealer.

EVs are not immune to potholes, curbs and rough roads. Just like every internal combustion vehicle on the roads, the shocks, struts and springs will eventually degrade to the point where they can no longer control the movement of the suspension.

Most EVs have a weight problem that works to your advantage. The weight of the battery and motor can make some EVs 1,000-3,000 pounds heavier than their internal combustion counterparts. This will cause extra stress on the suspension.

The “Edge Code” can tell you information about a brake pad’s friction material.

Knowing why the adjustment is required is critical to performing the total alignment.

The question customers fail to ask is, what is “best” for their vehicle?

The key to understanding the logic of air ride systems is using service information.

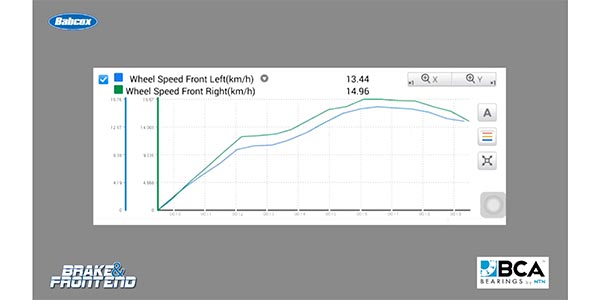

All wheel speed sensor codes are just the starting points of a diagnosis and not a reason to order a part.

It is important for the ABS/ESC module to receive two signals to verify the steering wheel’s position.

The source of the complaint can be the angles, electronics or tires.

With so many vehicles equipped with some form of ADAS, rethinking your electronics layout or plan might be in order.