Delphi Technologies is the only OE manufacturer that has a full-line ignition coil offering. Delphi Technologies’ ignition coil program covers 97% of European, Asian and Domestic applications with 392 SKUs, and serves as the OE on over 51 million applications. This ranges from a variety of vehicle manufacturers such as BMW, Buick, Cadillac, Chevrolet, Dodge, GMC, Honda, Mercedes-Benz and more. OE expertise goes into every coil Delphi Technologies makes, so have confidence in the OE manufacturer that’s created a world-leading ignition coil program to serve all of your customer’s needs.

Why do ignition coils fail?

Ignition coils are built to last, however, increasing demands placed on them can cause them to fail. Some of the main causes of failure are:

• Damaged spark plugs or plug wires

• Worn or excessive spark plug gap

• Vibration damage

• Overheating

• Varying resistance

• Excessive moisture

Repairing your ignition coil

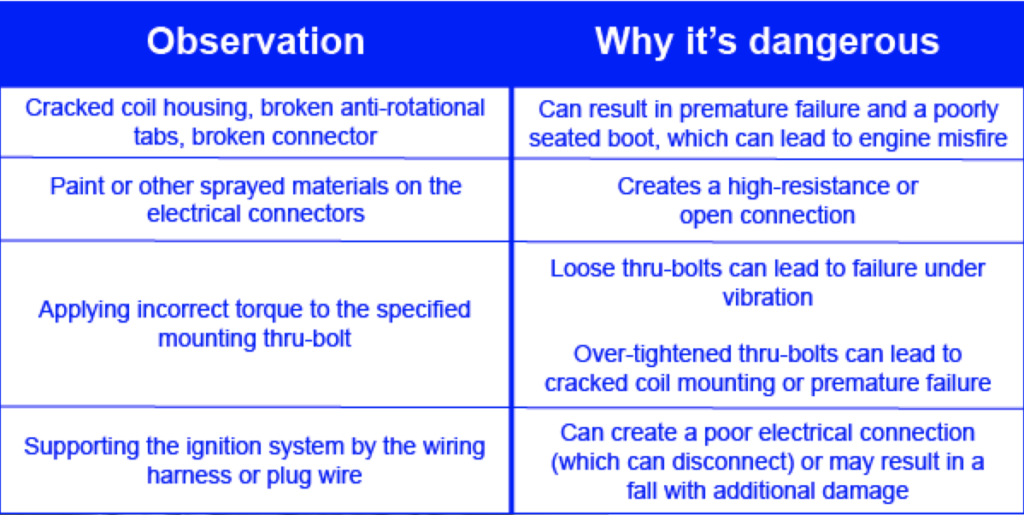

Once of the most critical aspects of the repair process is the environment. In addition to the regular stressors ignition coils experience, environmental contamination can also cause the ignition coil to fail. Be sure to take the following precautions such as:

• Using proper safety/sanitary equipment, such as safety glasses or gloves

• Blowing away debris from injector feed line and fittings

• Using lithium grease (sprayed onto injector feed line and fittings)

• Not wiring the brush injector

Wiring where it counts: Delphi Difference

When you eventually replace your ignition coil, trust Delphi Technologies for a repair done right the first time. With over 100 years’ worth of ignition coil experience, we’ve come up with multiple ways to improve on the design and wiring.

• OE-engineered for efficiency and a streamlined path to the spark plug, reducing the occurrence of shorts

• Smart manufacturing controls wire length to keep voltage the same

o Delphi Technologies uses winding process techniques to control the length of wire between adjacent windings

o More length results in greater voltage differences, which in turn create more pressure that could break down the insulation and wire coating

• High-quality wire coating resists imperfections (cracks, pinholes, etc.) that lead to failure

OE coils with multi-charge technology

Designed for challenging engine operation conditions in GDi vehicles, our multi-charge ignition coil technology has led up to 20% better fuel economy and reduced emissions.

As the OE in multi-charge technology for Mercedes and Infiniti applications, Delphi Technologies has produced over 1.2 million coils for North America with future OE business planned for both through 2028.

Want more information on our ignition coils? Visit our resource center, product page, or look through our parts catalog.

Have questions about our parts? Call us at +1 (877) GO-DELPHI.

Delphi Technologies is a brand of BorgWarner Inc.

This Article is Sponsored by: Delphi Technologies