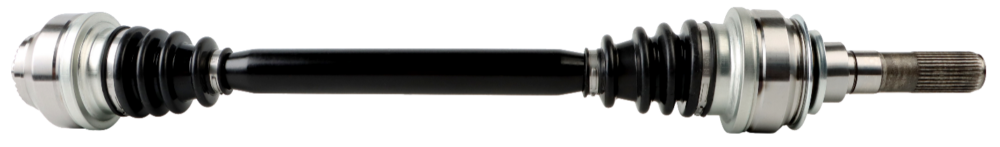

Today’s vehicle drivetrain systems are far more complex and powerful than ever before. So, you want to make sure you choose a replacement axle that matches the original OE design attributes to ensure proper performance and durability. Avoid installing an inferior axle based on price only, that may not perform properly or worse yet, fail in a few short months. The money saved initially may likely be more than offset by the additional replacement costs, as well as a potential lost customer.

There are two critical elements you want to consider when you are selecting a replacement CV axle.

1. Make sure the replacement cv axle that has been designed with the same attributes found on the original OE design. This is critical in maintaining original OE performance and dependability.

2. Choose an axle that has been designed to reduce noise, vibration, and harshness (or NVH) away from the vehicle while driving. NVH is one of the most common complaints on vehicles today and a cv axle that isn’t built to match OE attributes can cause problems after replacement that were not there in the first place.

SUV’s and CUV’s now dominate the market today and their drivetrains are more complex with significantly more horsepower than just a decade ago. So, it stands to reason cv axle technology has also evolved to handle today’s more complex, powerful drivetrains.

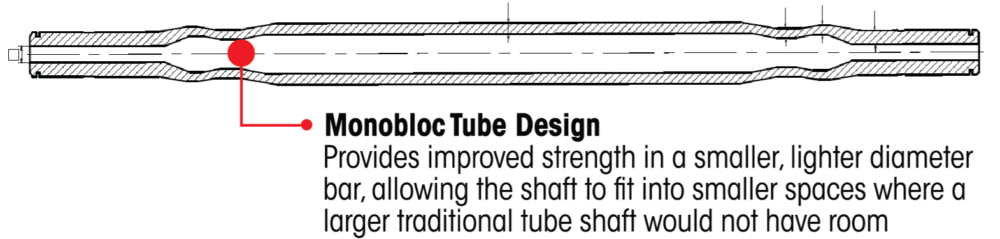

What is Monobloc OE CV Axle Technology?

TrakMotive’s New OE Innovations CV Axles are designed with the latest in axle technology including OE applications requiring one-piece monobloc center bars. The monobloc tube design can be precisely profiled to help cancel out NVH (noise, vibration, and harshness) and provides the same quiet, smooth operation as the OE design. *

The Key Benefits of the Monobloc Tube design are:

· Increased strength in a smaller lighter diameter bar

· The tube center section can be precisely profiled to cancel out the natural harmonic frequencies specific to a particular vehicle to greatly reduce noise, vibration, and harshness (NVH)

· Are specifically designed for specific late model applications where space is limited and is required to ensure proper fitment

· Provide the same dependable quiet, smooth ride as designed by OE

* Where Applicable OE

All TrakMotive® New Premium C.V. Axles are manufactured and engineered to the highest quality standards in the industry, ensuring they meet or exceed OEM manufacturer’s specifications in fit, form, and function.

This includes all new OE quality materials such as neoprene or thermoplastic elastomer (TPE)* dust boots and stainless-steel clamps to provide better resistance to deformation, stretching, and corrosion. Additionally, all the necessary hardware needed for the job is included to help eliminate the possibility of running back to the parts store a second time.

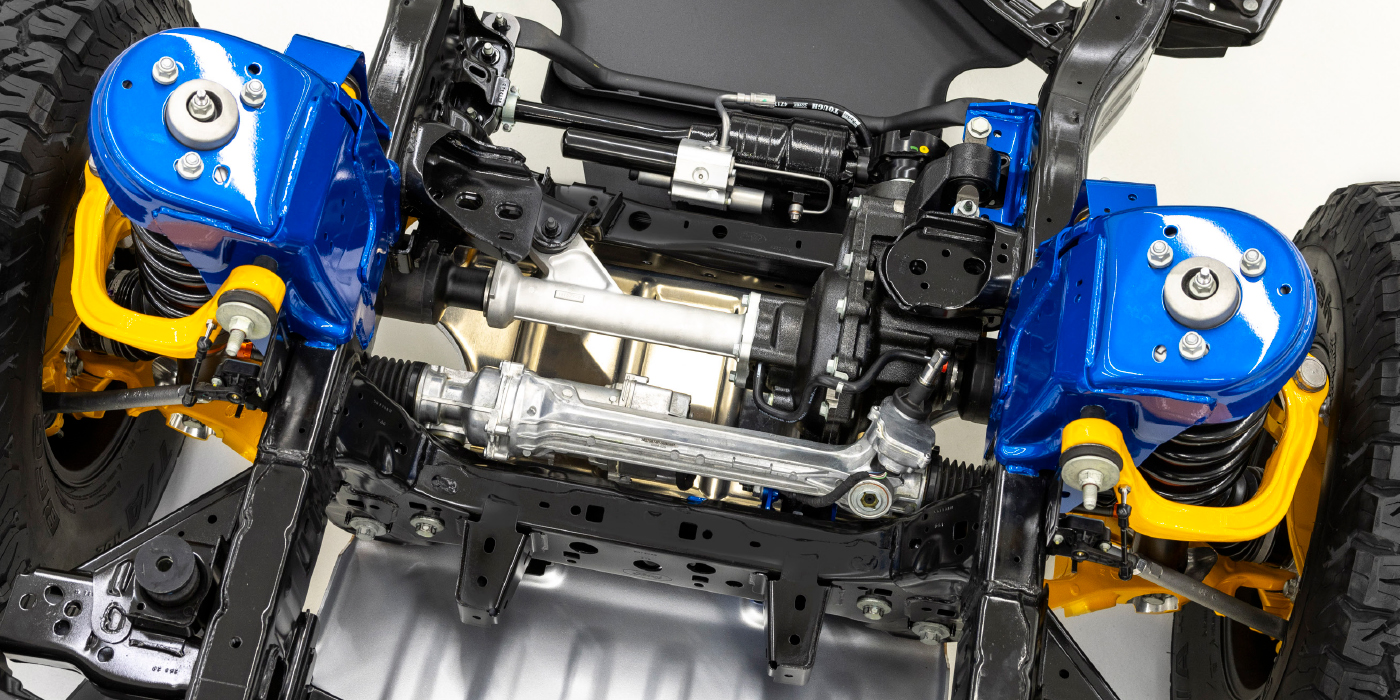

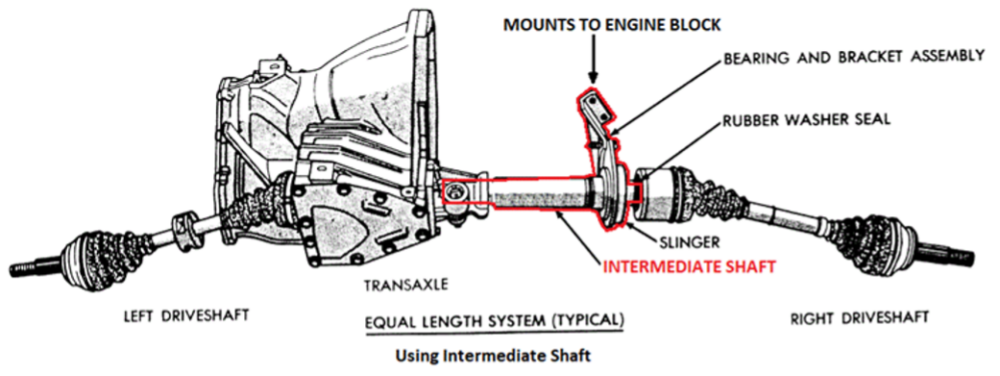

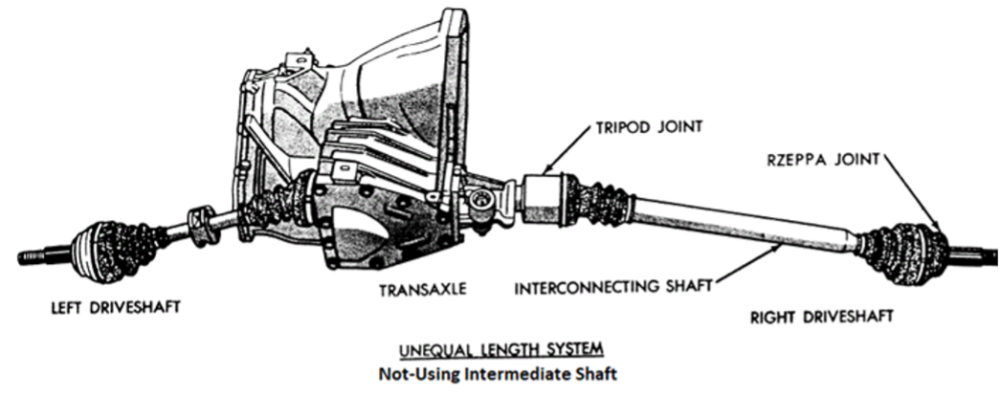

TrakMotive New Intermediate Shafts Also Available

What are they… and what do they do? Intermediate shafts, often referred to as “stub shafts” or “inner shafts” act as the link that couples the CV axle to the transaxle or differential. They allow for the removal and installation of CV axle assemblies without the need to disturb or replace the transaxle or differential oil seal. The intermediate shaft connects the CV axle to the transmission and ensures that the left and right CV axles are of equal lengths. The equal joint angles between the left and right CV axles reduce torque steer and improves vehicle handling.

Often, only the intermediate shaft may need to be replaced when the entire CV is initially thought to be at fault. Fix the Cause – Not the Symptom!

For more detailed information, explore the benefits of our entire CV Axle offering https://www.trakmotive.com/