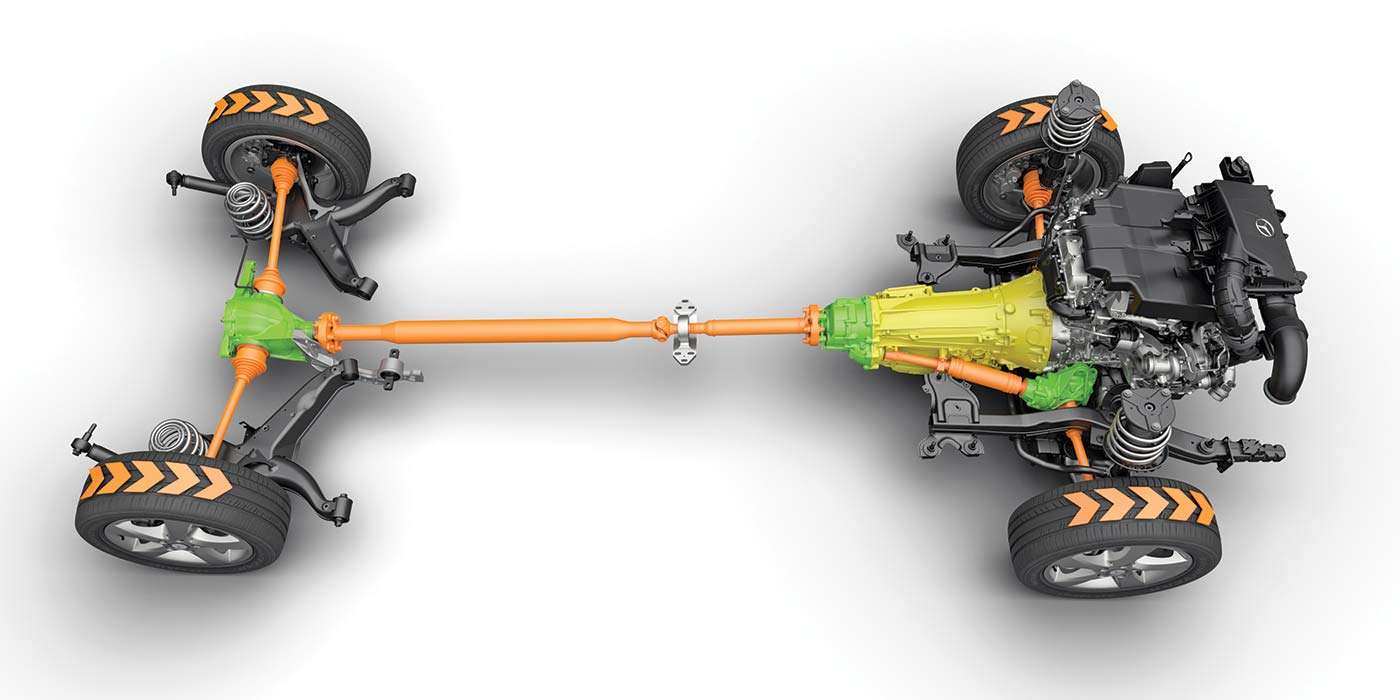

Vehicles equipped with 4×4 or all-wheel-drive (AWD) systems are designed to provide advantages throughout the year, but winter tends to bring these vehicles into focus. Technology has provided a means for an evolution with these systems, especially with active differentials that are controlled electronically.

One benefit of the computerization of these drivetrain systems is added diagnostic capabilities. Vehicle manufacturers have come a long way from passive limited slip, locking and viscous coupling systems. Today’s intelligent systems are constantly analyzing effectiveness and efficiency at all times. The challenge for these systems is deciding what type of correction will be the most effective to gain traction and stability for not just an axle, but individual wheels as well. These systems must also work with the ABS and engine management systems.

Passive Systems

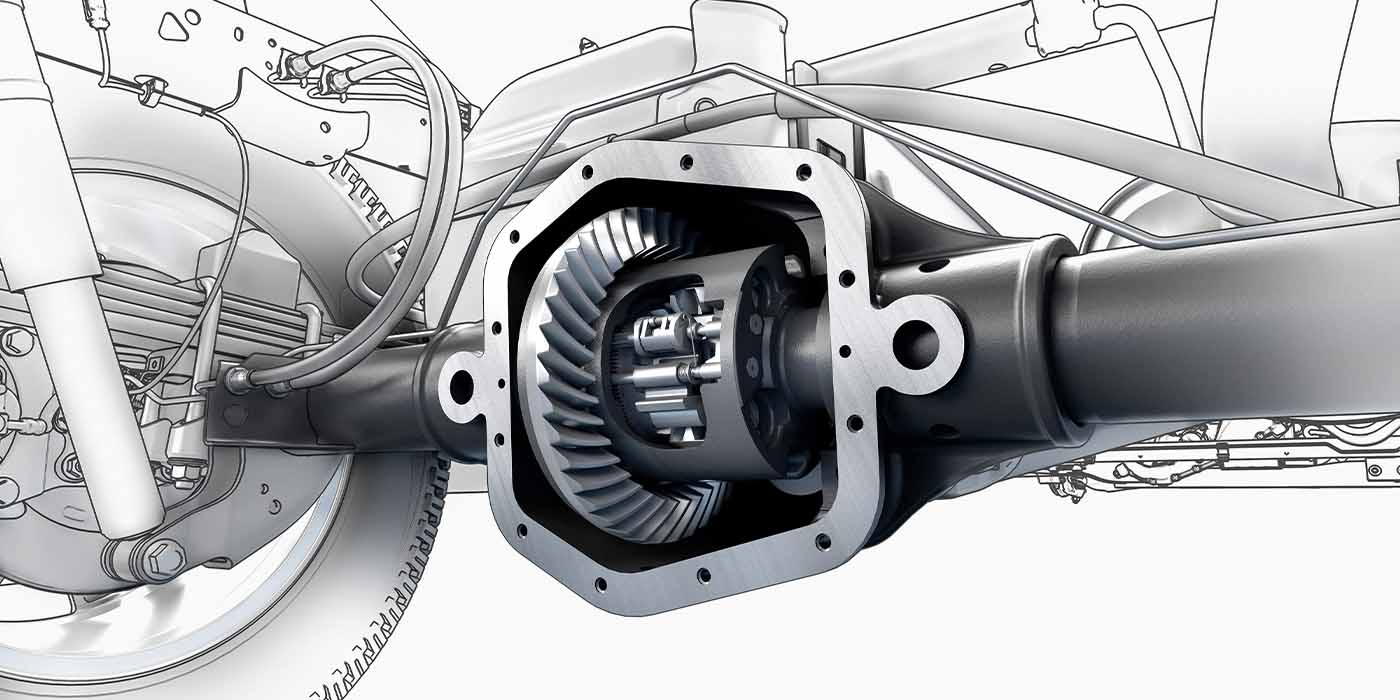

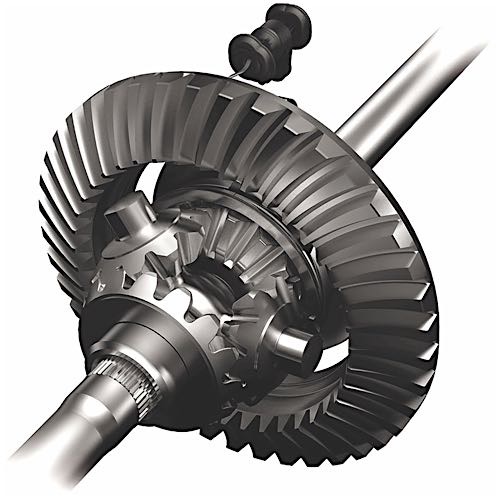

Differential gears allow for speed variation between wheels during cornering by allowing the outer wheel to spin at a higher speed independently from the inner wheel. This open-differential design can’t effectively transfer torque to the wheels under low-traction applications.

Locking and limited-slip differentials can transfer torque to the wheels with the most traction and equalize torque in that axle.

It is important to know and understand that AWD systems are designed for added traction, not work applications like 4×4 systems. Early viscous coupling-designed systems proved to work initially, but also brought their own set of failures. The older AWD systems utilized mechanical and hydraulic components, allowing torque transfer through the clutches.

Active Systems

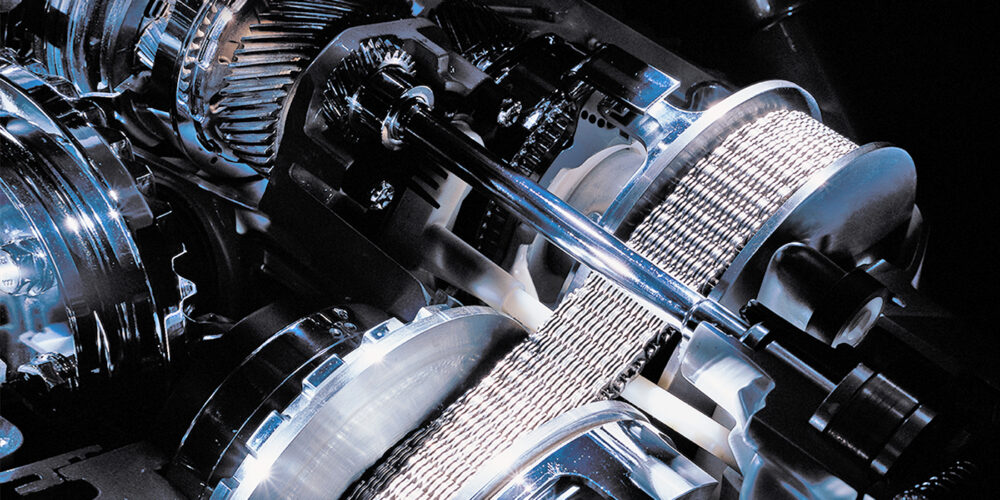

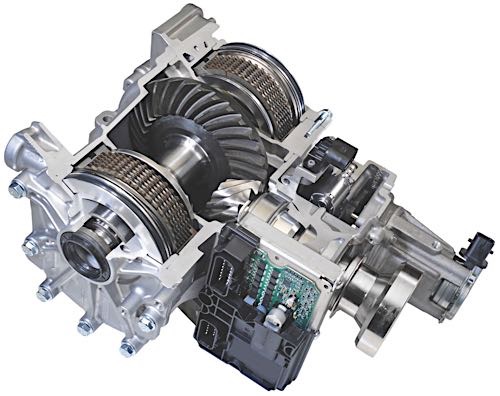

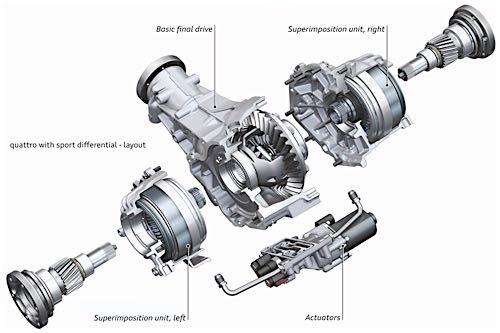

Adding computers, actuators and sensors to the differential assemblies enables computer control of the drivetrain. Depending on the vehicle, you may find these coupling units on the driveshaft, transfer case or the drive axle (side to side).

Slip and torque transfer ratio are controlled by the AWD module(s) for the differentials. Some performance applications may allow the driver to control the power bias, but most vehicles are subject to the computer’s demands based on vehicle and driver input. Controlling power to independent wheels allows for the best results regarding positive traction per wheel.

The module can demand partial or full application via amperage output or pulse width modulation. This will result in more or less pressure on the clutches, allowing slip or full application of the on-demand feature. Although this also holds true for axle-to-axle control, one great advantage of on-demand axles is the added fuel efficiency. Using the AWD system only as needed allows the assisting axle or hubs to free spin and reduce the load on the transmission and engine. This helps improve fuel efficiency especially at highway speeds where AWD is not needed.

Tire Size

Many of these systems are extremely sensitive to tire size change. Many TSBs, as well the service information, will state there should no more than a 2/32nd’s difference in the tread at any time from wheel to wheel (not just on the same axle). This could lead to premature system failures due to overheating of the unit. The computer will understand it to be wheel spin (slip) and will correct accordingly.

Viscous coupling systems will overheat as they try to remedy the situation mechanically as designed. Many systems could hide the problem before supplying fault codes.

Codes

With the addition of sensors, actuators and modules to the drivetrain comes malfunction codes. Accessing these codes and data will require a scan tool that can communicate with the modules that control the differentials. Some scan tools will be able to perform bi-directional tests to help with diagnostics.

Like transmission and engine control modules, the goal of the software is to prevent damage to the mechanical components. If the sensors detect a condition that could damage the system, like high or low fluid temperatures and pressures, the system will go into a self-preservation or limp mode. This mode might disable the active differential or limit the operation of the system.

Modules for these systems might need to be reflashed as the OEMs introduce new calibrations to address problems the engineers did not anticipate. Always check the software version and the TSBs to see if the OEM has introduced new calibrations.

Electrical Issues

Drivetrain modules aren’t always located in the most logical of places. They might be on the transfer case, under the vehicle or under the hood. Because of this placement, it is very common to find compromised modules with water intrusion and other circuit problems.

These modules are often on the hi-speed CAN network. The differential module communicates with the transmission, ABS and engine modules to carry out stability and traction corrections. If the CAN bus lines are damaged, you will have U- or communications codes. Other issues can occur if the components have compromised power and grounds.