The safety of a vehicle relies on the condition of the suspension, steering and drivetrain, to ensure not only the tires remain in constant contact with the road, but that the proper alignment angles are maintained during the full range of suspension travel.

This includes the shocks and struts, as well as control arms, steering knuckles, ball joints, tie rods, wheel bearings and CV drive axles.

All these components are inter-related and only when they all perform correctly will all vehicle suspension, handling braking and traction control systems work as designed.

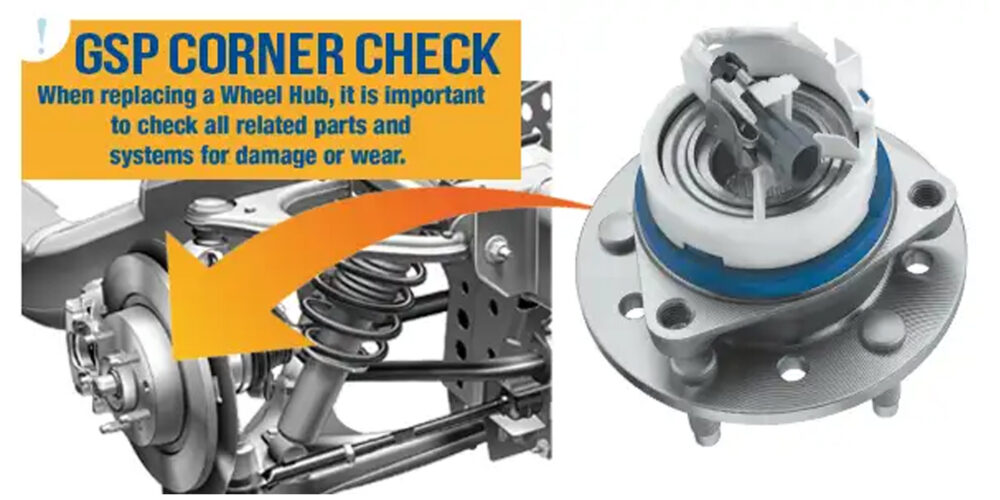

A comprehensive corner check should be part of a normal inspection routine, and it’s important to remember that installing some new components when others are worn won’t restore proper vehicle performance:

You can’t install a perfect part into an imperfect system, and GSP recommends performing a corner check as part of your normal service, allowing you to provide your customer a comprehensive evaluation of vehicle condition, giving them piece of mind and confidence in the thorough service you offer.

THE ASPECTS OF A CORNER CHECK

The corner check starts with a mental note of vehicle mileage. service history and any concerns the customer may have. When the vehicle is first pulled in the bay, start with a bounce test at each comer of the vehicle. This is specifically different than attempting to bounce just the front or rear suspension from the center of the car, which won’t yield the same results. Not only is the physical force we can generate as a human distributed evenly between left and right, which means we haven’t induced as much suspension travel, but we also can’t focus our vision to determine the results of the test on both sides at the same time.

One you have noted the results of the bounce test, your inspection continues when the vehicle is raised off the ground. Inspect the struts and springs for signs of wear and inspect all ball joints and tie rod ends.

Look closely at suspension bushings and sway bar links for wear. Inspect the steering knuckle for any signs of damage and look for play in the wheel bearings. Finally, inspect the CV axles for worn or damaged boots or leaking grease.

When necessary, refer to manufacturer service information for any specific procedures regarding component inspection. This is particularly important on vehicles with active or adaptive suspension, on which many of the normal characteristics of a traditional suspension may be different.

Depending on the reason a vehicle is in for service, a final evaluation of steering and suspension may need to be performed with a test drive, and in some cases, this will precede pulling the car in the bay.

How does the car handle during acceleration, braking, turns and other maneuvers?

Any bouncing or excessive movement of the suspension during acceleration and braking can indicate the struts need replaced, and any abnormal noises should be noted so you can focus your inspection on identifying them.

CONNECTING WITH YOUR CUSTOMER

After explaining why the corner check is part of your normal routine and the affects worn components can have on vehicle performance and safety, it’s a service your customer will come to expect. In addition, when you perform a corner check on every car, you benefit from recognizing the normal characteristics of any given vehicle, and you can document when any vehicle components are starting to show signs of wear.

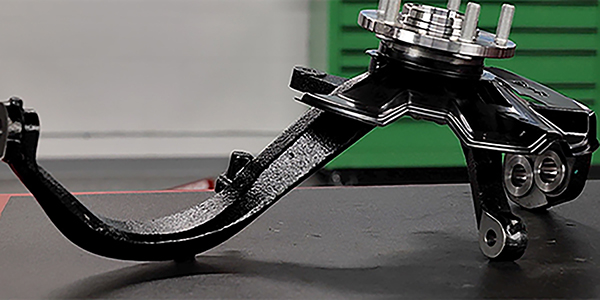

Your customer will appreciate your proactive and thorough approach to service, and necessary repairs won’t be a surprise to them when they reach that point. GSP loaded struts and shocks are designed to fit and function like OE. GSP also offers wheel hub and completely assembled knuckle hub assemblies, as well as CV axles, all of which are designed for precise DE fit and function.

Your customer will benefit from the confidence of investing in a product that features the durability and endurance they are used to, and as technicians we can rely on proper fitment right out of the box, providing trouble free installation.