Your customers rely on their vehicles to get them safely from point A to point B, and they also rely on their brake pads and brake rotors to provide reliable stops each and every time. So how does the vehicle’s friction system work and what role do disc brake pads play?

Once you understand how brake pads work and which friction material is best suited for which driving application, you can then select the right type of aftermarket brakes for your customer’s vehicle and driving needs.

What are brake pads and what do they do?

Brake pads are a critical component of the vehicle’s braking system, providing the friction that allows the vehicle to stop smoothly and securely, every time.

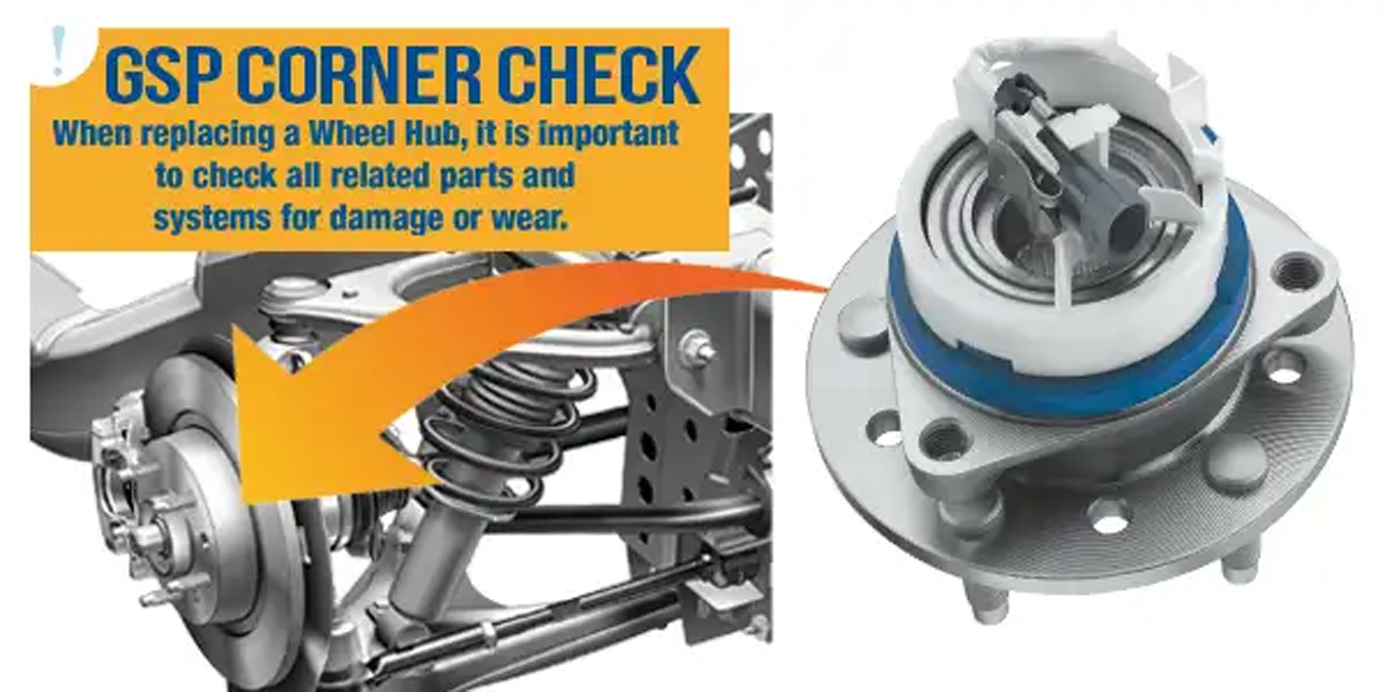

A disc brake system (different from a drum brake system) consists of four major components: the wheel hubs, brake rotors (discs), brake pads and disc brake calipers. All of these components work in harmony during a braking event to slow or stop a vehicle in motion. The brake pads contact the brake rotor and apply friction/pressure based on pedal inputs from the driver. The friction/pressure applied will reduce the rotational speed of the brake rotor which in turn reduces the vehicle speed.

What are brake pads made of?

Originally, brake pads were made of asbestos, an effective but highly toxic heat-absorbing material.

Utilizing today’s technology advancements, brake pads fall into three categories: organic brake pads, semi-metallic (metallic) brake pads and ceramic brake pads.

ORGANIC BRAKE PADS

Organic brake pads are made of a mixture of common materials like rubber, carbon, glass/fiberglass and others, secured together by resin. These brake pads are suitable for everyday driving of non-performance vehicles and don’t produce much heat with stopping. These brake pads are often known as Non-Asbestos Organic (NAO).

SEMI-METALLIC (METALLIC) BRAKE PADS

Semi-metallic (or often referred to as just “metallic”) brake pads contain between 30-70% metals, like copper, iron, steel or other composites and often a graphite lubricant and other durable filler material to complete manufacturing. Semi-metallic brake pads can serve a variety of functions from every day driving to track performance.

CERAMIC BRAKE PADS

Ceramic brake pads are made of a durable ceramic compound, often fortified with other material to help with friction application and heat management. Prior to 2015, ceramic brake pads commonly contained copper threads for heat management and increased friction performance characteristics, but since then, the Environmental Protection Agency has called for the reduction of copper material in brake pads, mandating a reduction of copper content to 0.5 percent by weight, by 2025. While usually sold at a higher price point, ceramic brake pads are very quiet versus semi-metallic brake pads producing less dust as they wear and performing consistently at a wider range of temperatures and driving conditions.

What are the differences between ceramic brake pads and semi-metallic brake pads?

The difference between ceramic brake pads and semi-metallic brake pads is simple – it all comes down to the materials that are used to produce each brake pad.

When choosing a ceramic brake pad or semi-metallic brake pad for a vehicle, there are certain applications in which ceramic and semi-metallic brake pads both offer different advantages.

For performance vehicles, track driving or as the best brake pads for towing, most drivers prefer semi-metallic brake pads, as they provide better braking over a wider range of temperatures and conditions. They are made of material that conducts heat well, thus making them more able to withstand higher temperatures upon braking, while helping the system cool simultaneously. Semi-metallic brake pads can be noisier than ceramic brake pads and their price point normally falls between that of organic and ceramic brake pads.

Ceramic brake pads, while quieter, are also able to handle extremely high temperatures with quick recovery, causing less damage to the brake rotors. As they wear, ceramic brake pads create a finer dust than semi-metallic brake pads, leaving less debris on the vehicle’s wheels. Ceramic brake pads typically last longer than semi-metallic brake pads, and through their lifespan, provide better noise control and less wear-and-tear to brake rotors, without sacrificing braking performance. When deciding on ceramic brake pads versus semi-metallic brake pads, bear in mind that not all vehicle makes and models are compatible with ceramic brake pads, so research is advised.

Understanding how brake pads function and how different brake pad materials are suited for different applications will help you make the right brake pad selection to fit your customer’s unique vehicle and driving needs.

This Article is Sponsored By: Advics