In a perfect world, a flashing check engine light for DTCs P0301 through P0312 would always be solved by installing a new ignition coil. If this were true, technicians wouldn’t need countless hours of diagnostics training. The reality is that a misfire can be more than a missing spark from an ignition coil.

The Nature of Misfires

Misfires that are below the vehicles threshold often pass unnoticed, but a constant misfire is hard to be overlooked by you or the engine management system. These misfires would set a DTC inside the engine computer. Misfires that turn on the check engine light and log a cylinder-specific fault code are the easiest to diagnose, while random misfire codes can be more troublesome. The OBDII system can identify the cylinder(s) that are not contributing their normal dose of power and set a corresponding DTC. A P0303 DTC, for example, would indicate a misfire on cylinder number 3. If the ODBII system is unable to identify a specific cylinder a P0300 random cylinder misfire DTC will set. But, neither of these mean that the ignition coil or any other specific part is at fault. It simply means that more testing is necessary.

Coil Failures

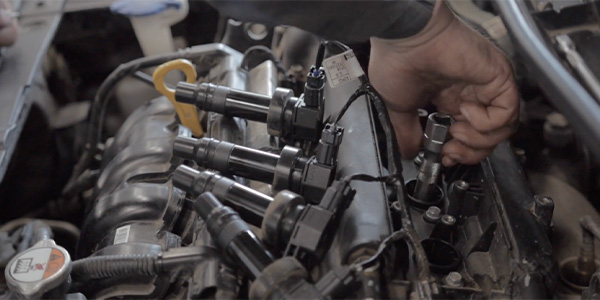

Ignition coils can vary greatly in size and shape but share three common parts. These are the primary windings, secondary windings and a non-conductive or dielectric insulation material that separate the two windings. The insulation material is typically a dielectric resin that is applied in a vacuum, so air bubbles are not formed. Air bubbles can create a path for electricity inside of a coil, and lead to premature failure.

Coils fail for a variety of reasons including heat, vibration, or issues on the secondary side of the ignition system. Coils are commonly found bolted to the cylinder head, either on top or inside of a cylinder specific well. Excessive heat and vibration can cause the insulating material to break down and create internal coil failure. Worn secondary ignition components such as spark plugs or wires can cause a coil work harder, require more voltage, and therefore significantly reduce the operating life of the coil. When a coil fails, it is possible the electricity created is unable to reach its destination, the spark plug. When this happens, the electricity created inside of the secondary windings looks for the path of least resistance to ground. This path is commonly found through the boot or body of the coil. Carbon tracking happens when oil, dirt, or moisture is electrostatically attached to the boot or insulator and creates a path to ground. When carbon tracking is found, the coil and corresponding plug should be replaced. It is also possible that a failed ignition coil can cause damage to the engine computer, or ignition control module.

Non-Coil Misfires

Commonly an engine computer detects a misfire by measuring the changes in crankshaft speed. This change in speed can be caused by a combustion event that is happening early, late, or not at all.

Worn spark plugs are one of the leading causes of misfires on a high-mileage engine. Over time, the large amount of voltage needed to create a spark erodes the electrodes, increasing the gap. This change in the spark plugs gap increases the voltage required to generate a spark. Eventually, the ignition system reaches a point where it fails to jump that gap, and the spark plug does not fire.

The air/fuel ratio can also cause a misfire. The state of the fuel and air charge (too rich or too lean) inside the cylinder changes how the spark forms and how much voltage is required to jump the spark plug gap, and create spark.

A lean misfire occurs when the predetermined air/fuel ratio is more air than fuel, or in extreme cases all air and no fuel. This can be caused by a fuel injector not spraying, a faulty EGR system, or anything that is forcing more air into the cylinder than the engine computer had planned for. A rich misfire is less common than a lean misfire. The most common rich misfire is caused by a leaking or stuck open fuel injector. Rich or lean misfires can also be caused by a failed oxygen sensor. The engine computer monitors the oxygen sensor to report back the efficiency of the combustion event. A skewed or dead oxygen sensor can cause the engine computer to incorrectly add or subtract fuel.

Replacing an ignition coil before diagnosing what is actually causing the misfire may seem like a tempting diagnostic shortcut. But, it can really set you back in your diagnostic process. So the next time you get a vehicle in your shop with a misfire, don’t just assume it’s a bad coil. Test, don’t guess.

For more information or questions about spark plugs you can reach out to the NGK Technical Support line by calling 877-473-6767 or visit them on the web at www.ngksparkplugs.com.