CC:

When an engine is designed, each cylinder is perfect. Each is an exact copy of its neighbor. The components within the engine are designed to be equal as well – injectors, spark plugs and ignition coils are engineered to function the same, regardless of which cylinder they serve.

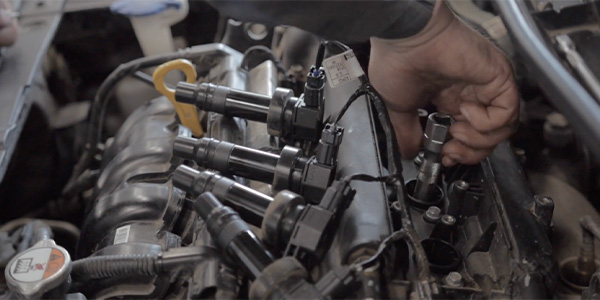

With all the cylinders the same, the engine is balanced. Of course, this also means that all the coils are subjected to equal heat and vibration under the vehicle’s hood. If the engineers use a balanced approach in designing the engine’s ignition system, why would you use an unbalanced approach to repair it?

Equally matched cylinders, combustion chambers and ignition components are easily created on the engineer’s computer, but in the real world, balance isn’t so easily achieved. It is not uncommon for one coil to fail and cause a diagnostic trouble code like P0301 for a specific cylinder misfire or for the ignition circuit like a P0351, indicating a malfunction or open in the primary side of the coil.

The fact is, the engine compartment is no place for the weak. It’s a rough environment for any component. Specifically, heat and vibration can break down the epoxy resin that holds the primary and secondary windings. Even the coil windings can be damaged by heat and vibration – this is one of the most common causes of these codes.

There are two practices some technicians use that can cause more ignition system problems than they solve. The first bad practice is swapping coils to isolate a misfire. The second practice is to replace coils one by one as they fail.

Both practices originated in the era of points and distributors when ignition systems were analog and not digital. Swapping coils was common because many coils were the same for most vehicles. You could take a “known good” coil from another vehicle to see if the problem was the coil.

Theoretically, this diagnostic practice works because, if a coil is not functioning, it will cause a misfire no matter what cylinder it is connected to – but this diagnostic approach does not take into account how the primary side of the coil is turned on and off.

It may be tempting to replace only one coil at a time to save some money, but while replacing one coil might cure the misfire and codes for now, the other coils could fall prey to the same failure and codes. This is why ignition coil manufacturers package coils in sets and recommend complete replacement for best performance.

On millions of popular engines, you must remove the intake manifold to gain access to the ignition coil. This adds additional effort and labor time to what can be a simple job – the best solution for your time and your customer’s piece of mind is to replace all of the car’s coils at the same time. Of course, properly performing and documenting the repair along with clearly stating the reason for your recommendations is always the right procedure.

And to maintain perfect balance, remember that spark plugs typically wear at the same rate as the coil. As the gaps increase, the voltage required from the coil also increases. Not replacing the plugs with today’s high-ignitability spark plug could leave the original cause of the coil failure in the engine. By renewing the plugs with the coils, you can assure the customer that the problem has been solved.

For more information visit NGKSparkPlugs.com.

Thanks for watching!