Vehicles affected: 2006-’07 Eos, GTI, Passat and Passat Wagon, and 2005-’07 Jetta 2.0L

Condition: The MIL is on, with DTC P0087 (Fuel Rail/System Pressure Too Low), P1093 (Fuel Trim 2, Bank 1 Malfunction) or P2293 (Fuel Pressure Regulator 2 Performance) stored in the ECM’s fault memory.

Condition: The MIL is on, with DTC P0087 (Fuel Rail/System Pressure Too Low), P1093 (Fuel Trim 2, Bank 1 Malfunction) or P2293 (Fuel Pressure Regulator 2 Performance) stored in the ECM’s fault memory.

This could be caused by excessive wear of the intake camshaft lobe that drives the high pressure fuel pump. The wear limits maximum pump piston lift, causing fuel rail pressure fluctuations. The wear on the camshaft lobe can also lead to wear on the base of the high pressure fuel pump cam follower.

Note: Please review with customer the importance of using proper engine oil. Use of engine oil that does not meet VW quality standards can cause premature wear to engine components.

Production Solution: Increase surface hardening of camshaft lobe for the high pressure fuel pump. Improved intake camshafts have P/N 06F109101B.

Service

If there are low pressure faults stored in the ECM like P310b or P129f, always diagnose low pressure faults first before diagnosing high pressure faults.

Note: Do not replace the high pressure pump for low pressure faults.

Remove the high pressure fuel pump and visually inspect:

1. The base surface of the cam follower in contact with the camshaft lobe.

2. The tip of the high pressure fuel pump plunger.

3. The high pressure fuel pump camshaft lobe.

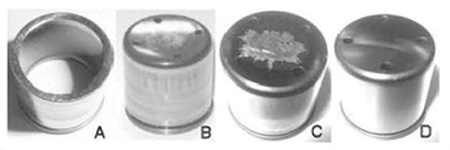

If the base of the cam follower looks like C or D in Figure 1, no excessive wear is present.

The cam follower and camshaft should not be replaced.

Tips:

• If excessive wear of the cam follower is found, an oil change should be performed on the vehicle following the repair.

• If the cam follower base surface is excessively worn so that its surface is concave (Figure 1, B) or missing (Figure 1, A), inspect the intake camshaft lobe for wear.

• If the high pressure fuel pump camshaft lobe shows excessive wear, replace the intake camshaft with P/N 06F109101B and the cam follower with P/N 06D109309C, see Group 15 Engine – Cylinder head, Valvetrain.

• Tool T10252 may not properly lock intake cam into position. Because of cam position, valve spring tension could cause cam to rotate clockwise (front of engine view). This will cause misalignment of sprocket teeth and chain. If this happens, rotate counterclockwise (front of engine view) until chain and sprocket teeth align; slack must be at top of drive. Rotating clockwise will cause timing to be off.

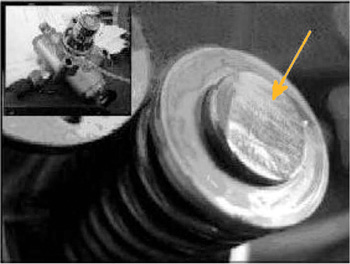

• Inspect the tip of the high pressure fuel pump plunger for excessive wear. See Figure 2.

Note: If the plunger tip of the fuel pump is not worn, do not replace the fuel pump.

• If excessive wear is found, the high pressure pump must also be replaced. (See Group 20 Fuel Supply.)

• High pressure fuel pump plunger damage is only possible if the cam follower base has a hole in it and the plunger tip has come in direct contact with the camshaft lobe.

• If no excessive wear can be found in the high pressure fuel pump cam follower or intake camshaft lobe, or if the damage is found in camshafts with P/N 06F109101B, create a Technical Assistance Contact Ticket under the Concern Type Engine and Engine Electronics.

• If excessive wear of the cam follower is found, an oil change should be performed on the vehicle

following the repair.

Attach the complete diagnostic log to the contact, and call the VW Technical Assistance Center for

further assistance.

Courtesy of ALLDATA.