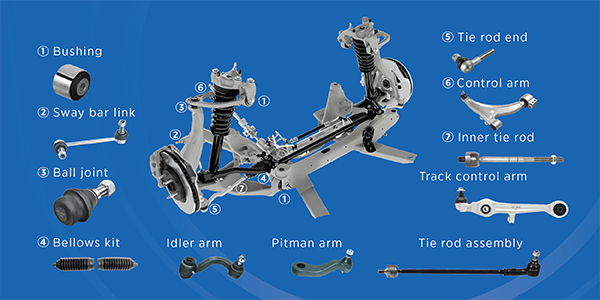

The future of steering and suspension in action

We’re proud to be an aftermarket supplier for Tesla steering and suspension components. One of the biggest challenges with hybrid and electric vehicles is the weight of the battery, which oftentimes adds a couple hundred pounds. This additional weight impacts vehicle handling and maneuverability.

To combat this, we use lightweight materials to help offset battery weight, resulting in a lighter chassis that ensures a safe and quiet ride. We not only met the OE standard for control arms and ball studs, but exceeded in strength, durability, and fatigue life while also accounting for Tesla’s multiple driving modes.

Experience the Delphi Technologies difference

Ball joints

• High precision ball pin with smoother finish for durability, smooth joint operation and superior angle dynamics

• High specification grease for longer service intervals

• High-grade chloroprene rubber cover keeps out contamination from dirt and water

Bushings and Bellows

• Engineered bushings replicate OE shore hardness values provide improved damping properties and better ride comfort

• Strong bond allows for excellent load-bearing capabilities

• High quality rubber bonding reduces delamination issues while providing enhanced ride comfort and damping properties

Control Arms

• Chloroprene rubber boot improves durability and protects against contamination

• High specification grease for longer service intervals

• Tough bushings provide high load resistance and noise insulation

• Best-in-class pressing method measures each joint load to ensure full seating and proper breakaway torque

Sway Bar Links

• Reinforced link rods making our parts strong and sturdy for a long service life

• Application-specific hybrid composite end caps reduce weight with increased durability

• Wear-resistant sockets help support load and protects against wear caused by dirt and debris

Tie Rod Ends

• Tech-friendly grip points feature a hex flat at threading point for an easy grip with a standard wrench and easy repair with no extra tools needed

• Low-friction, high-performance thermoplastic bearing matches OE specifications for seating and rotational torque

• Rust-beating cataphoretic coating on housing offers premium protection against corrosion from salt, dirt and water

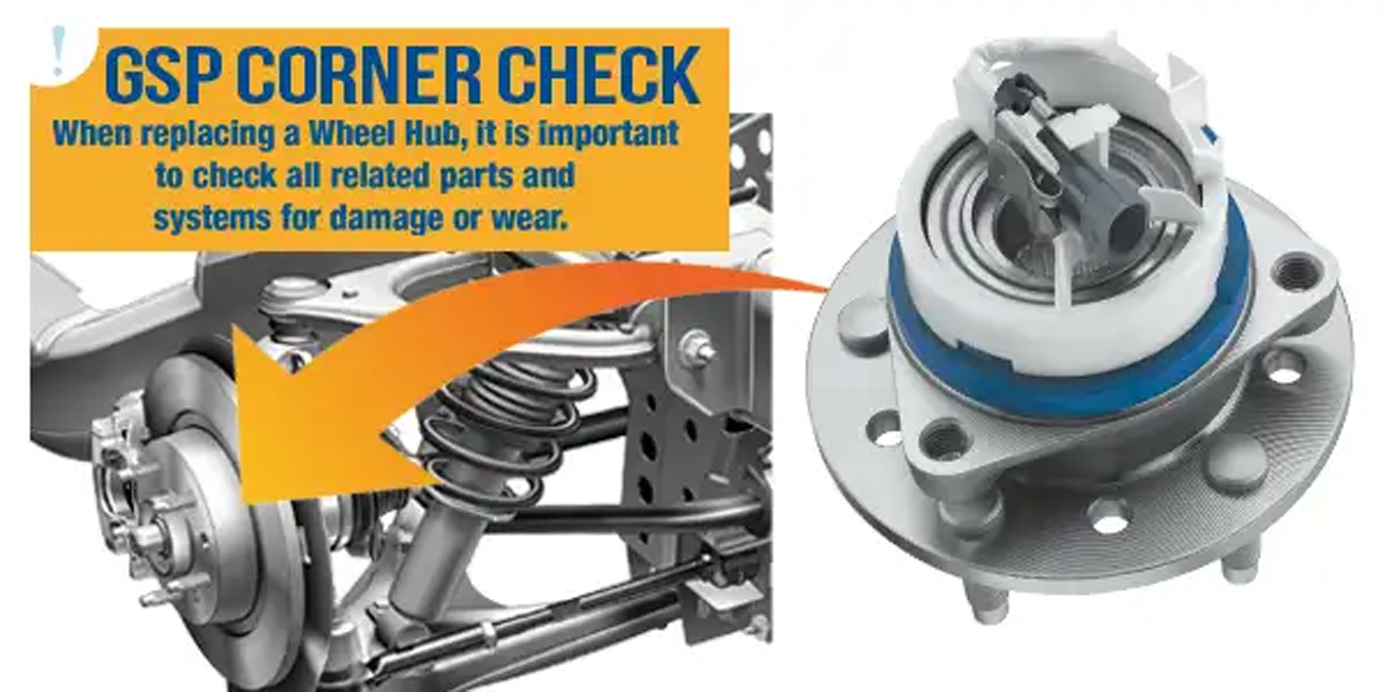

We’ve got your back

Our support doesn’t stop once the component arrives at your doorstep. We’re by your side every step of the repair. Benefit from:

• Expert-led training programs

• Online tutorials, videos, and resource center

• Technical support hotline staffed by ASE Master technicians and OEM experts

One of our expert technicians, Dave Hobbs, routinely hosts trainings and provides tech tips videos. Click the video below to learn more about high and low-tech steering and suspension.

Steer into your Delphi Technologies future today. Visit us at delphitechnologies.com or our parts catalog for more information on our steering and suspension offerings.

Delphi Technologies is a brand of BorgWarner Inc.