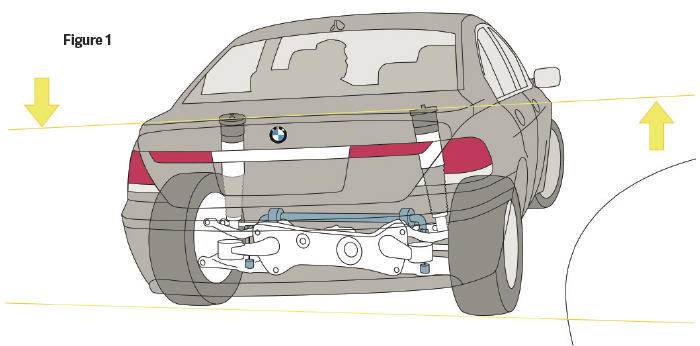

Roll bars, also known as sway bars or anti-roll bars, are responsible for controlling body roll when a vehicle goes around a turn. How do they do this? A roll bar is basically a long spring that connects both sides of the suspension across an axle. When a vehicle goes around a turn, the weight will transfer from one side to the other, compressing the outside suspension. The roll bar applies force to the inside suspension and reduces the amount the body can roll (Figure 1).

Roll bars on modern vehicles are oftentimes a compromise between stability and comfort. The larger the diameter of the sway bar, the less the body will roll. However, that same larger diameter roll bar will cause the vehicle to roll side-to-side when driving over uneven terrain. This can be quite uncomfortable for passengers inside the vehicle, and it’s far from ideal in a luxury vehicle.

OEMs will select certain roll bars to control oversteer and understeer of the vehicle. A stiffer front roll bar will increase understeer, while a stiffer rear roll bar will increase oversteer. Traditional sway bars cannot be adjusted on the fly, but Active Roll Bars (ARBs) can.

Where It Started: Hydraulic ARBs

ARBs were introduced in the mid-to-late 1990s in some European vehicles. ARBs started to become a bit more common, though they were typically part of a high-cost performance suspension option. This means that they’re not overly common on vehicles, but you will see them from time to time.

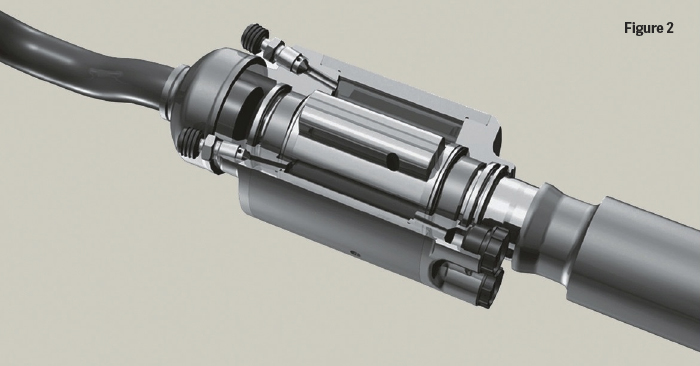

Hydraulic ARBs use hydraulic fluid to apply torsional force against the roll bar (Figure 2). This is similar in principle to how hydraulic power steering systems apply force to the steering gear to provide steering assist. The hydraulic fluid is supplied by the power steering pump (Figure 3) and is routed through an electronic valve body or valve block (Figure 4). In this type of system, you’ll typically see the power steering referred to as the hydraulic pump since it provides fluid pressure to both the power steering and hydraulic ARB systems.

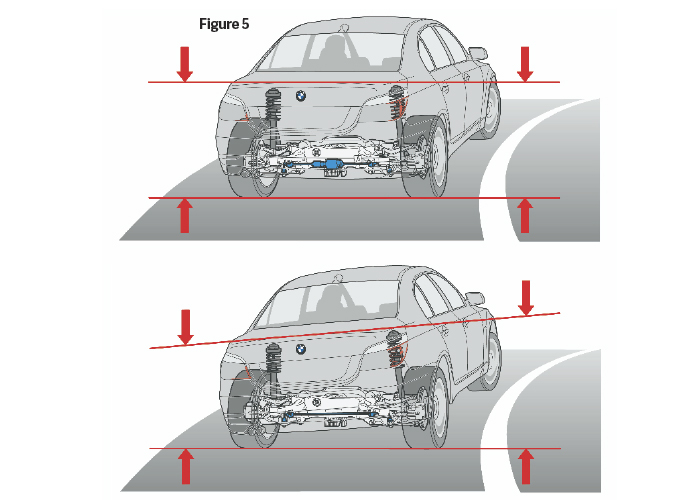

The hydraulic pressure is controlled by a dedicated control module and can be adjusted based on information from a number of vehicle sensors. These include, but are not limited to, the vehicle speed sensor, individual wheel speed sensors, ride height sensors, yaw-rate sensors, as well as steering angle and/or steering force sensors. All of these data inputs are used to calculate the hydraulic force required to keep the body roll in check (Figure 5).

These hydraulic ARB systems are vulnerable to a number of possible issues. Leaky hydraulic lines, fittings, or seals can cause hydraulic pressures to drop. Old, dirty hydraulic fluid may not perform at its best, hampering system performance. A faulty hydraulic pump, accumulator, or even the engine drive belt could all reduce the effectiveness of the ARB. And of course, electrical issues such as corroded connections could wreak havoc with the data inputs, causing erratic operation or even an illuminated MIL.

It’s important to advise your customers of the importance of regular maintenance on vehicles that are equipped hydraulic ARBs. A little bit of preventive maintenance, such as a fluid flush or drive belt replacement, could save them thousands of dollars in repairs if left alone.

Where It’s Headed: Electronic ARBs

Hydraulic ARBs offer a number of advantages, but they have one big vulnerability: the hydraulic fluid. The hydraulic lines can rupture or leak, the fluid can wear out or become contaminated, and those are just a few. The real hangup for hydraulic ARBs is the speed at which the system can make adjustments; it’s slower than modern electronic systems. You may be asking, why would the system need to make quick adjustments to the roll bars? Stability control.

Let’s think about how different roll bars will affect the way the vehicle handles. A stiffer front roll bar will keep the vehicle more level in a turn, but it will cause the vehicle to understeer. A stiffer rear roll bar can stabilize the rear of the vehicle during turns but can cause oversteer. However, if the control module was able to make on-the-fly adjustments to the stiffness of the front and rear roll bars, it could make a real difference in an emergency maneuver, swerve, or skid recovery.

The control module will analyze data from vehicle sensors and make adjustments as needed based on programming. These sensors may include vehicle speed, individual wheel speed, yaw rate, steering angle, steering force, ABS activation, etc.

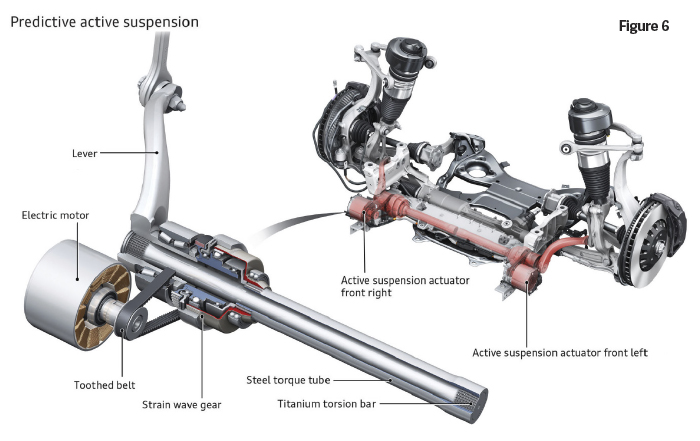

It’s easy to spot an electronic ARB underneath the vehicle. Simply look for large gauge wires running to an actuator on one side of the roll bar. Some ARBs may feature a built-in actuator which wraps around the roll bar, or you may find that the electric motor is mounted separately, then connected to the ARB by a toothed belt (Figure 6).

Audi uses electronic ARBs in a number of vehicles including the S8, SQ7, SQ8, RS Q8, and more. These electric motors operate on 48 volts DC.

Tips, Tricks, & Common Failures

All roll bars, both standard and active, are vulnerable to common failures. Worn out or broken end links will render the roll bar ineffective. Once the roll bar loses its connection to the suspension, it can’t do its job effectively. If the roll bar bushings are worn out or ripped, the roll bar could shift around under load instead of transferring that load where it’s supposed to go.

If there is a leak in the system, air could be drawn into the fluid causing cavitation, or the fluid could leak out. Hydraulic lines and hoses could be damaged from impact, corrosion, dry-rot, just to name a few.

Check the hydraulic fluid level, its condition, and the type of fluid used. Not all hydraulic fluids are the same, and the pump could whine or make abnormal noises if the incorrect type of fluid is used.

For electronic ARBs, focus on the electrical connections, and the sensor/data inputs. We all know how a corroded battery terminal can affect the performance of a 12-volt DC system; the same goes for these higher voltage systems. Faulty sensor readings can wreak havoc with an ARB, so it’s important to ensure that all applicable sensors are providing a good signal before condemning an ARB as faulty.