Understanding The Downside

The introduction of ADAS calibration to the repair process has created a huge learning curve, but the repair industry is getting more up to speed on ADAS with each passing day.

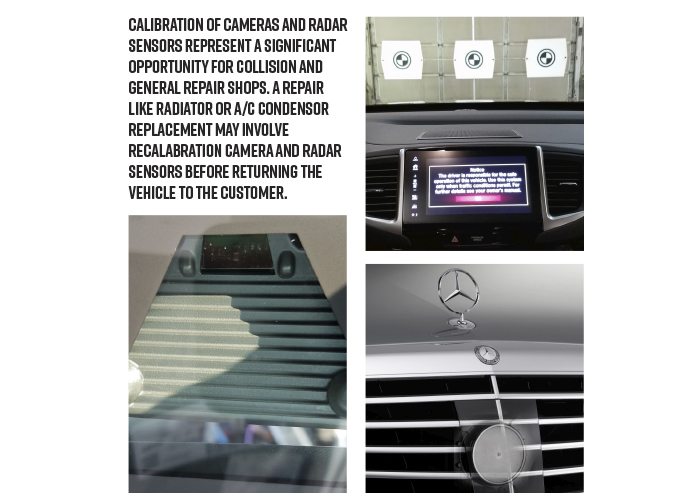

Today’s collision repair professionals are more likely to understand the high degree of precision required to calibrate ADAS systems, and it’s becoming common knowledge that minor fender benders, or even simple repairs like windshield replacements or repainting, can throw off ADAS sensors to a significant degree. In addition, a growing number of collision repairers are learning about the exacting environmental conditions that are required for static ADAS calibrations – the need for OEM-specified equipment and targets, perfectly level floors, nonreflective paint, clean room-like conditions in spacious calibration areas, and freedom from interferences created by sunlight, shadows, posters or even technician’s clothing.

On the other hand, rising awareness of the revenue-generating potential of ADAS calibration is leading to a phenomenon that collision repairers and insurers should be concerned about: the explosion of mobile ADAS calibrators.

A MATTER OF MILLIMETERS

In my home state of New Jersey, we’re seeing rapid growth of aftermarket companies offering ADAS calibration conducted via “portable systems.” What we’re seeing in New Jersey looks something like this: the operator finds a random parking lot, pulls a targeting system out of the back of their vehicle and conducts the calibration.

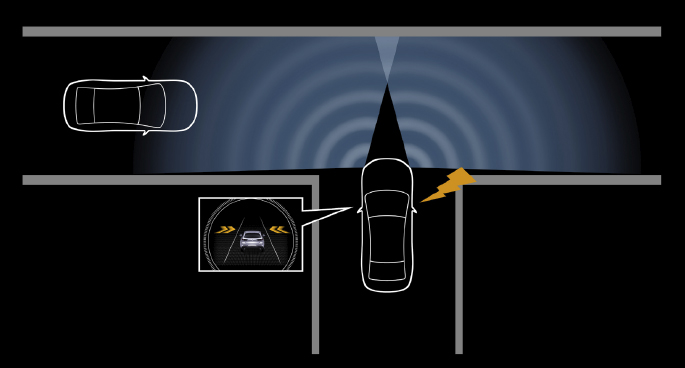

Properly calibrating ADAS systems is not a matter of inches, but rather millimeters. To use a simplified example, let’s say the system sees 50 feet down the roadway. When you multiply even a tiny mis-calibration by that total distance, you end up with a significant chance of that system failing to perform as intended. Quite literally, the car could fail to brake in time as a direct result of the faulty calibration. And, bear in mind, the fact that a mis-calibration has occurred can be largely invisible to a driver or insurer. They may feel reassured that the warning light has gone off, but an experienced ADAS professional knows that, during the calibration process, something as simple as a metal trash can left too close to the vehicle could confuse the ADAS system. The warning light would go off just as readily as if the camera or radar had hit the six-inch metal target, per OEM specs.

IMPROPER CALIBRATIONS

As a business owner who has invested heavily in an environment created exclusively for conducting ADAS calibrations, I’ll admit that I have a large stake in the trajectory of this sector.

But here’s why mobile ADAS is an issue that should be on the radar screen of everyone in the collision repair and insurance industries, in addition to those conducting ADAS calibrations in properly controlled conditions: at our shop, we’re being asked more and more frequently to redo ADAS calibrations that were conducted improperly by aftermarket “mobile” operators.

The inaccuracies associated with some mobile ADAS operators could drive up costs. With enough time, this could translate into more pressure and stress for shops. It’s even more likely to become a problem when you consider how much easier it is to run a mobile operation than to invest in a dedicated facility that meets manufacturer specifications.

MY SHOP

In my shop, which is dedicated exclusively to ADAS, about 900 square feet is set aside just to store all of the targets and tools that I’ve purchased.

From an environmental standpoint, in my shop we have protected our calibration areas from exterior light sources (like sunlight streaming in through windows) and actually use a lumens meter so that we can put the exact, manufacturer-specified illumination on our targets. On one wall, there are eight different light switches just for controlling shadows. You’ll even see two light fixtures installed right next to each other – one LED, the other fluorescent – so that we can use the right light source, per the manufacturer’s specifications.

NOT OPTIONAL

When a vehicle is repaired after being in a collision, ADAS calibration isn’t optional – it must be performed. But if you can control the environment, you can control severity. Doing it right the first time needs to be the top priority, because the only way to calibrate a misaligned system is to do a teardown. You take the bumper off of that car or disassemble that camera to inspect the mounting surface – and do the calibration all over again. In other words, with mobile ADAS outfits, what should have been a $300 calibration ends up running $600.

I could put 10 crews on New Jersey roads and make a lot of money by doing mobile calibrations. But, I have chosen to stick with OEM targeting in a tightly controlled environment staffed by committed, highly trained technicians. Having conducted more than 1,500 calibrations at this point, I am convinced that this is the only way for the industry to keep moving forward amid the tech-driven transformation of modern vehicles.