If you purchase almost any set of brake pads or shoes, the last three or four digits of the parts number match for most of your brand choices. This is not an accident or OEM conspiracy. This is the product of more than 60 years of cooperation of brake friction manufacturers. This collaboration is the Friction Materials Standards Institute (FMSI) and the FMS number system. The fruits of this endeavor go beyond part number; it has given shops new brake applications sooner and at a lower cost.

In 1948, FMSI was founded as a trade association of automotive aftermarket friction manufacturers. Since that time, it has performed a valuable service for the automotive aftermarket – the creation of a standardized part numbering system for brakes and clutch facings.

During the post-WWII period, the friction material industry was facing a tough situation as the post war economy started to boom and the auto makers were rolling out the first brand new models since 1942. Also, the friction material marketplace was far more diverse, complex and local than it is today. A lot more businesses were putting friction materials on shoes and managing the cores.

If you owned a shop in the 1940s and 1950s and were performing a reline job, you had many options. You could call your part supplier and have them send over a new set of shoes, or you could order a “friction set” and rivet the linings to the cores yourself. If you had a specialist that did just brake linings, you could just exchange cores for bonded or riveted relined shoes. This diverse distribution chain was starting to become a liability for a safety related product like brake linings.

In response to this difficult marketplace and an explosion of new applications, aftermarket friction product suppliers banded together to form the FMSI.

Challenges

Brake friction products are about the only parts category where the majority of manufacturers work together to develop a voluntary nomenclature for part numbers and a way to share information. Not even tire, spark plug or chassis component manufacturers have been able to form a similar group.

The primary mission of FMSI is to maintain and enhance this standardized part numbering system for all on-highway vehicles in use in North America. Not only do the manufacturing members have the right to use this system, but their customers who sell the parts do as well. This means that from manufacturer through parts store and shop, one part number is used as the standard and as a common language — the FMS number.

FMSI does more than just issue part numbers, they help to share new friction material information among the members. This includes scientific, engineering, technological, statistical and other relevant information. Every time an automaker turns out a new platform, FMSI builds a profile on the application.

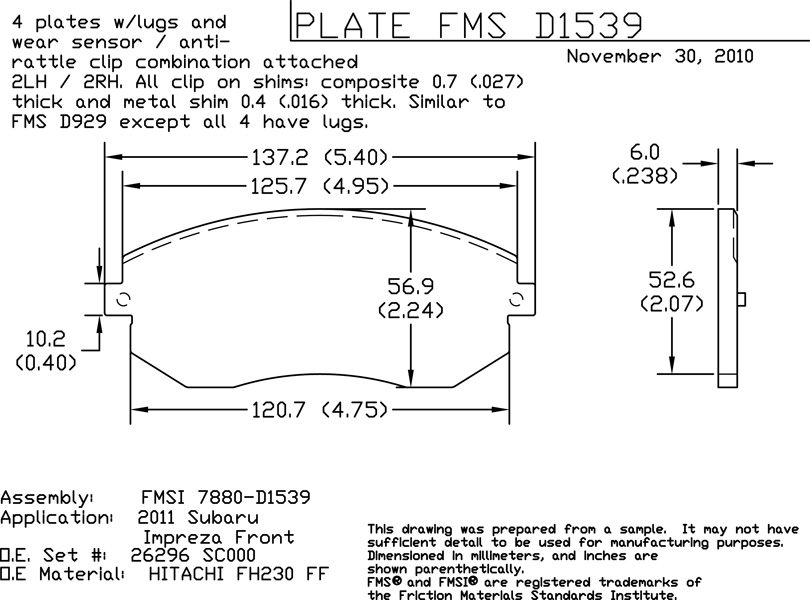

For a new application, the information includes the physical dimensions, hardware and how the application is put together. Within the profile, the information includes the OE part number, edge code and other information that can be collected from the OE sample part.

Members of FMSI can use this information in manufacturing and managing their catalogs. Membership in FMSI is open to any manufacturer of friction and related products covered by the trademarked FMSI and FMS part numbers; this includes the companies that supply backing plates, hardware and shim materials. Other participants in this industry may be eligible for licensee membership.

Due to the global nature of today’s friction material industry, the intellectual property of FMSI is coming under attack from non-members. The most common violation is to use the FMSI catalog information without becoming a member.

Both FMSI and FMS are registered trademarks of the Friction Materials Standards Institute. These marks have been registered in most of the important automotive aftermarkets in the world. FMSI has also trademarked various part numbers that make up its standardized part numbering system.

All dues paying members of the Institute are authorized to use, within specified limits, these marks in connection with the order, purchase, offer or sale of friction materials identified by part number and drawing promulgated.

In order to protect FMSI’s intellectual property, the Institute is going after not only the violators, but the suppliers who purchase the products by issuing cease and desist orders.

FMSI will vigorously enforce its rights against any unauthorized use of its trademarks and copyrights.

When you consider that often the brake pads are replaced before any other part including the tires, the most important advantage FMSI gives is to shops and consumers in the form price and rapid availability of new applications. In most industries each company must perform this service by themselves at substantial cost.

Current Members

–ABS Friction Inc.

–Advics North America

–Affinia Group, Inc. (Raybestos)

–Akebono America Inc.

–Anstro Manufacturing Company, Inc.

-Besser Brake Pads, LLC

–Bosch Brake Components LLC

-Brunner International Inc.

–C.M. Brake Inc.

–Capital Tool & Design Ltd.

–Ceco Friction Products

–Delphi Chassis Systems

–Duramax, S.A.

–Ebra Friction Technologie

–Federal-Mogul (Wagner)

-Franco-Mex, S.A

–Fras-Le North America, Inc.

–Fricciones Tecnicas y

Maquinados, S.A.

–Friction Division Products

(FDP)

–Gonher de Mexico

–Honeywell Friction Materials

(Bendix Brakes)

–Iroquois Industries Inc.

-Motion Control Industries

-New World Friction

–Newtek Automotive

-Nucap Industries

–O.E. Quality Friction, Inc.

–Performance Friction Corp.

–Rome Tool & Die Company

–Satisfied Brake Products

-Silverline America

–Tek-Motive, Inc.

–TMD Friction, Inc.

–Uni-Bond Brake, Inc.

–Wellman Products Group (Hawk)