Selling, mounting and balancing custom wheels can be a profitable business, but what about tire pressure monitoring system (TPMS) sensors? According to the National Highway Traffic Safety Administration (NHTSA), it is a violation of the TREAD Act to disable the system, which includes vehicles with aftermarket or custom rims.

In early 2011, the Tire Industry Association (TIA) reached out to the NHTSA regarding scenarios that shops commonly face when servicing vehicles equipped with TPMS. TIA was specifically addressing the so-called “make inoperative” provisions of NHTSA’s TPMS regulations and if they apply to the aftermarket and custom rims. This was NHTSA’s response:

“We assume that the vehicle has a functioning TPMS system at the time he or she purchases aftermarket tires and wheels. In that case, a service provider would violate the ‘make inoperative’ prohibition of 49 USC 30122(b) by installing new tires and wheels that do not have a functioning TPMS. To avoid a ‘make inoperative’ violation, the service provider would need to decline to install the new tires and rims, use the TPMS sensors from the original wheels (if they are compatible), or convince the motorist to purchase new TPMS sensors and ensure that the sensors are properly integrated with the vehicle’s TPMS.”

By law, you can’t disable the system because the customer doesn’t want to pay for your shop to install or transfer the TPMS sensors to the new wheels. In the eyes of NHTSA, neglecting the sensors is like removing an airbag to install a video screen or removing a catalytic converter to achieve more performance.

OPTIONS

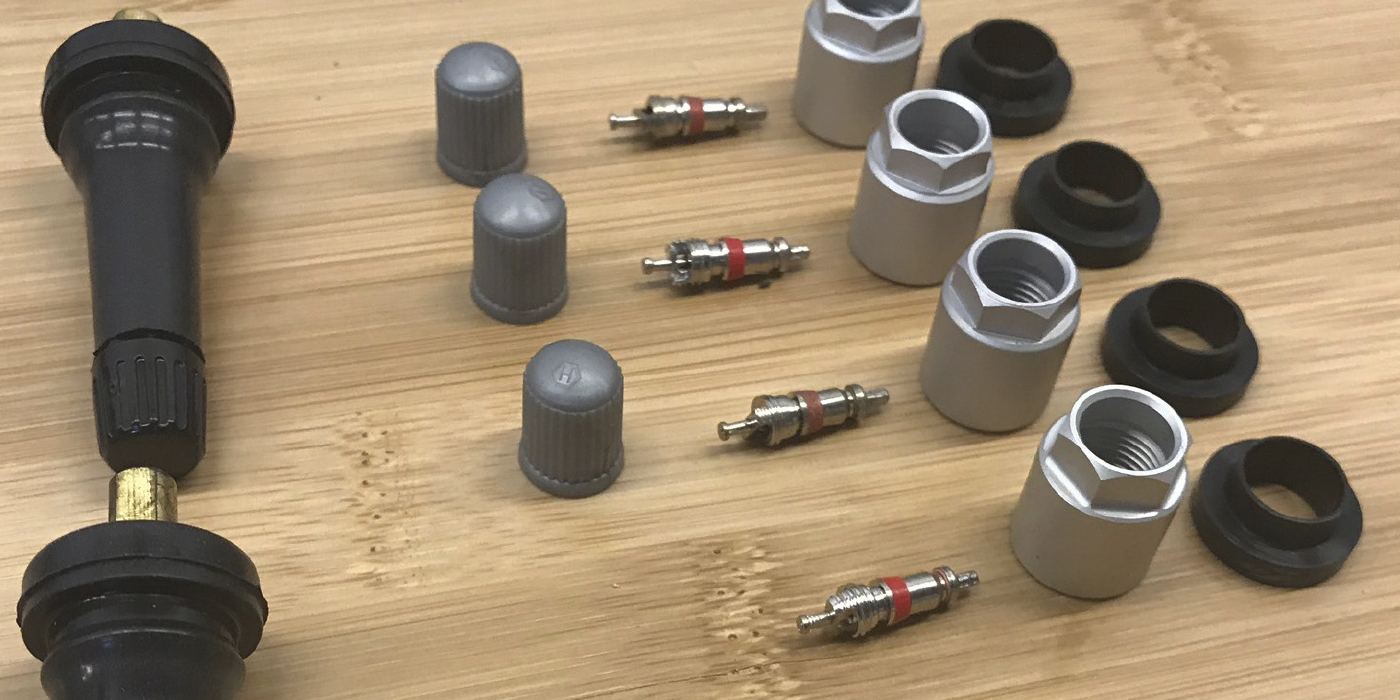

Most valve stem holes come in a few sizes, with the most common being 0.453” and 0.625” for snap-in stems. For TPMS valve stems, the size of the hole can be larger for some snap-in and clamp-on holes, but the real problem can be the anatomy of some custom wheels. The valve stem areas may not have the correct size and shape, affecting how a TPMS valve stem seals. Also, some custom rims can have drop-centers, barrels and flanges that don’t match up with the original rim or TPMS sensor. But there are some options.

Option 1: Aftermarket Stems and Seals

There are aftermarket stems and seals that can seal stock sensors to custom rims. These can keep the proper orientation and location of the sensor.

Option 2: Banding the Sensor

If it is impossible to fit the sensor in the original rim hole, you can attach the sensor with a kit that bands the sensor to the drop center of the rim. These kits come with a metal band and a mounting tab for the sensor. The sensor is attached to the tab using the stock attachment method. When mounting the sensor, make sure it is mounted flat and in the same orientation as it was on the stock rim.

Make sure the sensor is attached across from the valve stem. Knowing where the sensor is can prevent damaging the sensor when mounting the tire.

Option 3: Looped Valve Stems

This option allows you to mount the TPMS sensor to a mounting hole on the back of the valve stem. These can work for clamp-on sensors on wide truck rims.

What Not To Do

Do not epoxy or glue the sensor directly to the center of the rim. Chances are the epoxy or adhesive will not hold up to the heat generated by the brakes and tires. The sensor will dislodge and bounce around the inside of the wheel.

Do not try to seal the sensors in an airtight container to fool the system. These “TPMS pipe bombs” might work and might not work depending on the type of sensor and relearn procedure. Also, newer sensors have accelerometers that activate the sensor when the wheel is turning to save the battery. Without this type of motion, the sensors may not wake up properly and cause the TPMS light to come on.

TPMS is the law. Disabling the system so a customer can run custom rims eliminates the main tool preserving a customer’s investment in rims and tires in the first place.