Today’s engine management systems are okay with substituting a value from another sensor to keep the engine running while the check engine light blazes. But, ABS systems do not like to guess the speed of the vehicle. If an ABS module does not like the data from a wheel speed sensor, it shuts down and sets a code. If the vehicle has stability control or ADAS features like automatic braking, those systems will be taken offline by one malfunctioning wheel speed sensor.

For the technician, it can be frustrating. The wheel speed sensors are some of the longest circuits in the vehicle. Also, since the ABS shuts down the system if there is a problem, it can be challenging to replicate a symptom in the bay.

The critical part of any wheel speed sensor diagnostic procedure is to understand the criteria setting the codes and how the electrical circuit can cause that code.

Erratic or Loss of Signal Codes

Codes for erratic performance can be caused by the physical relationship between the wheel bearing encoder ring and the wheel speed sensor. These codes are generated when the module processing the signal can not rationalize the changes in speed when compared to the other wheels, or the laws of physics. All wheel speed sensor codes are just the starting points of diagnosis and not a reason to order a part.

Erratic wheel speed sensor codes are set because the module can’t rationalize the output of a sensor. If the module sees a dropout of the signal from the sensor, it would translate into the vehicle stopping in inches and then accelerating back to that speed in a few inches. The software controlling the ABS knows this is not possible, so it sets a code.

Most of these codes can be replicated during a test drive after the code is cleared. This can be done with a scan tool, but most codes are cleared when the key is cycled.

Open, Short and High/Low Codes

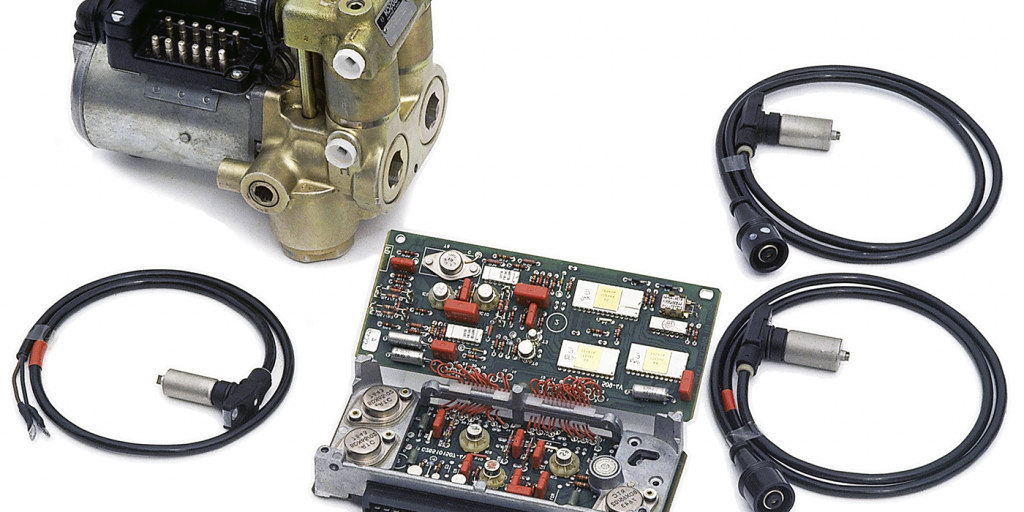

Every time the ABS modulator wakes up, it does some housekeeping. It says, “hello” to the other modules on one of the high-speed networks like the engine management systems, supplemental restraints and electric power steering. It will start to talk to the yaw, acceleration and wheel speed sensors. To check on the wheel speed sensors, it pokes them with a bias voltage signal.

A bias voltage test is a five-volt signal that only lasts for a few milliseconds. If no voltage comes back, the ABS knows there is an open or break in the circuit. If the same voltage comes back, the circuit is probably shorted to ground. If too much voltage comes back, it is a short to power. If not the right voltage reading comes back, it knows there is high or low resistance in the circuit. It is fundamental Ohm’s law applied to test the integrity of a circuit.

To read the voltage with the system on, you will have to back-probe a connector or use a bypass harness to clear the code from the ABS module to test the circuit.

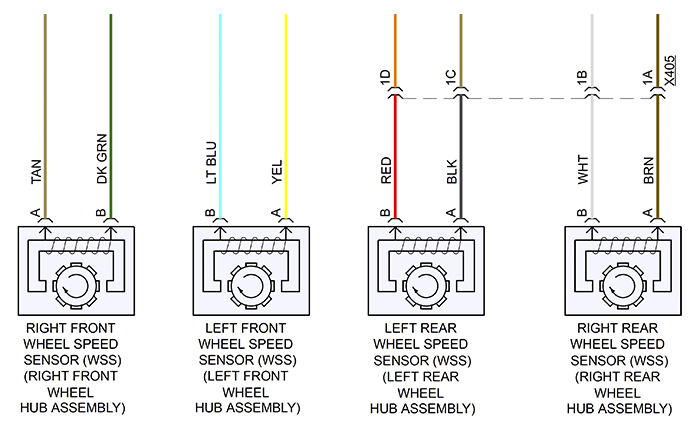

If you have access to the connector at the ABS modulator and the pin connections, you can measure the resistance in the entire circuit. You can also measure the resistance at the connector in the wheel well, if possible. This can help you to focus your diagnostic efforts on a specific section of wiring.

You need to confirm the resistive value of the wheel speed sensor, which should be between 1,000 and 2,500 ohms (top tip: check a known-good wheel speed sensor on the opposite side of the vehicle to get the exact value). On some vehicles, the values will be different from front to rear. Some manufacturers will use more sensitive active wheel speed sensors in the front and passive sensors in the rear. The two types of sensors have different resistive values.

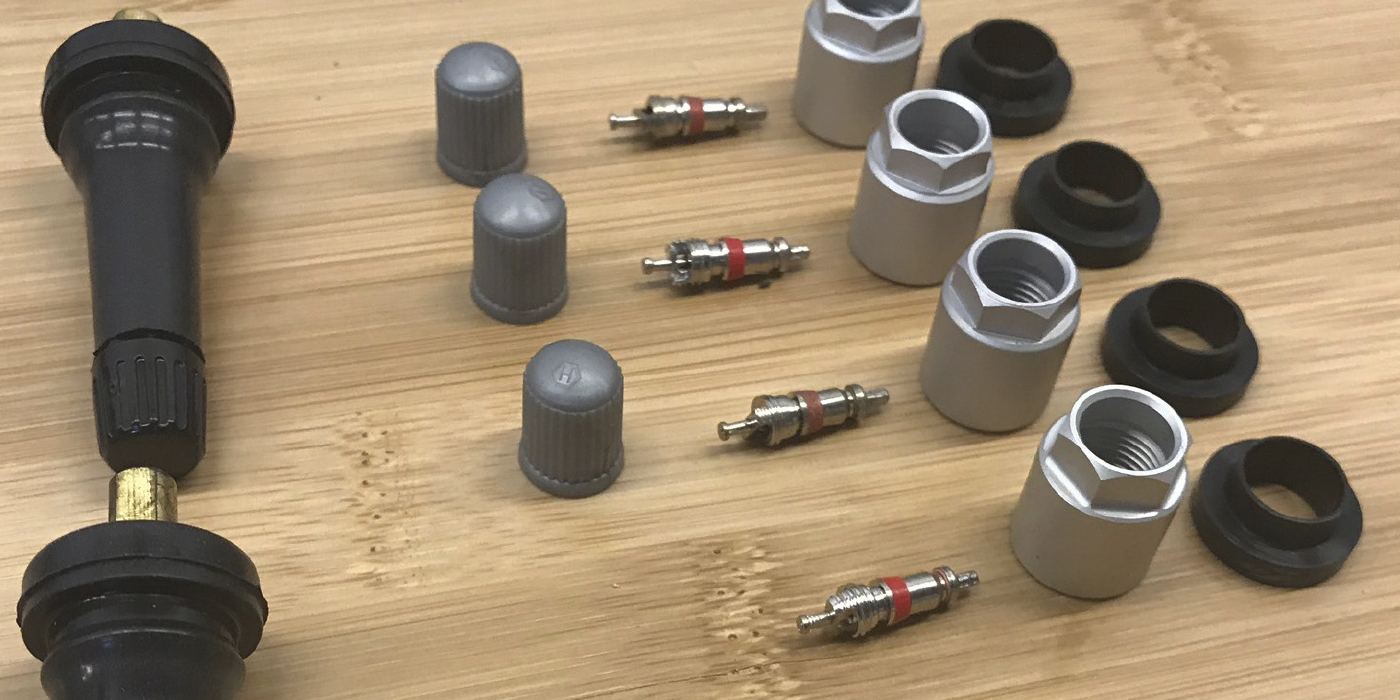

Wheel speed sensors have copper wire coils suspended in epoxy or plastic in the head of the sensor. The sensor is exposed to the heat of the brakes and moisture on the road. The epoxy can break down and allow coils to be exposed to the elements. Also, the knuckle can corrode, and the oxidizing metal can crush the sensor.

Next, examine the integrity of the wiring. Also, measure the output of the voltage or the presence of a bias voltage to confirm the operation of the module.

Scoping Speed Sensors

When a scope is attached, you will have to adjust your voltage scale and cursors to see the 0.6- to 1.2-volt changes in the 5-12 volt range. The waveform should be clean and consistent. Missing peaks and valleys can indicate damage to the reluctor or encoder ring. In some cases, the magnets of the encoder ring will attract metallic debris, causing the waveform to skip between peaks and generate codes for an erratic signal.

If you are diagnosing an active wheel speed sensor, a low current amp clamp can be used to check circuits for operation and bias voltage. It will not be able to see with the same resolution as a voltage test, but it can confirm if the module is providing power and even a bias voltage signal. The only problem is finding a section of the harness where the two wires are divided in the wheel well.