This is the year of the TPMS (Tire Pressure Monitor System). It’s been coming for some time. In response to a rash of highly publicized rollover accidents caused by tire failures on SUVs, Congress passed a law called the TREAD Act in 2000 which required all vehicle manufacturers to have TPMS on all their cars and light trucks by 2008. Time has run out, and as far as we know, all the vehicle manufacturers have complied.

No one disputes the benefits of TPMS, but a hodgepodge of different technologies from various supplies means there is no common diagnostic, service or relearn procedures for these systems. The only thing they have in common is that they illuminate some type of warning light if tire pressure drops 25% or more below the recommended inflation pressure. So if a tire is supposed to carry 32 psi, the low-pressure tire warning light should come on if tire pressure drops to 24 psi or less.

TWO TYPES OF TPMS

TWO TYPES OF TPMS

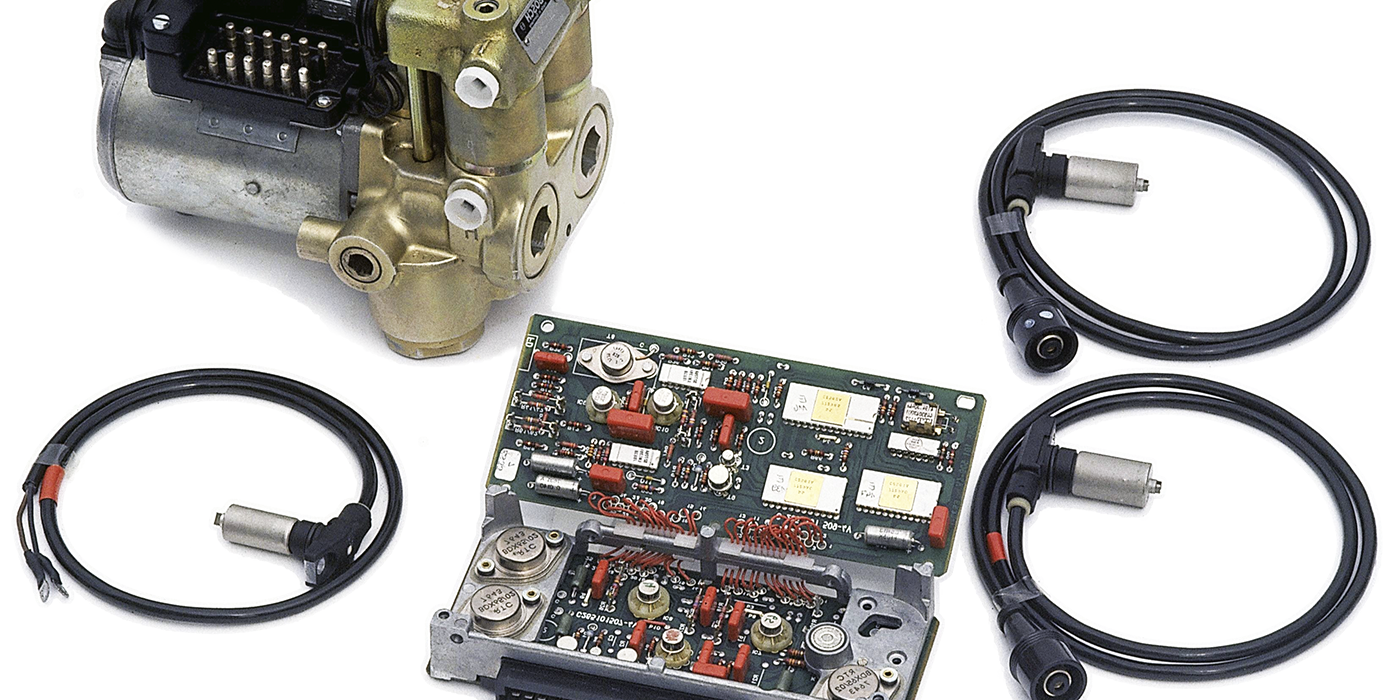

There are two basic methods for monitoring tire pressure: “indirect” TPMS systems and “direct” TPMS systems. Indirect TPMS systems do not use pressure sensors inside the tires, but instead use the wheel speed sensors that are already part of the ABS system to monitor and compare relative wheel speeds. Loss of air pressure from a tire will decrease its diameter and produce a slight change in the speed of that wheel. Indirect TPMS systems are not as sensitive as direct TPMS systems, and are used only on a few import applications (such as 2001-‘02 BMW M3, and 2003 and up BMW 3-Series, 7-Series and Z4). On the other hand, indirect TPMS causes fewer problems and requires no special service procedures when changing or rotating tires.

Direct systems monitor the air pressure inside each tire with a wheel-mounted sensor. These systems started appearing around model year 2000 on a growing number of import vehicles including Nissan Quest, 2001 Audi A8 & Quattro, 2002 Infiniti Q45, 2003 Nissan 350Z and Murano SUV, and 2004 Mitsubishi Endeavor to name a few. One way to tell if a vehicle has a direct TPMS is to simply look at the valve stems. If the stems are held in place with nuts at their base, the tires may have pressure sensors inside. The sensor is usually located at the base of the valve stem inside the wheel (though, on some applications, the sensor may be mounted in the drop center inside the wheel and held in place with a steel band).

The sensor contains a pressure transducer, battery and transponder that periodically broadcasts an FM signal. The battery may be replaceable in some sensors, but is usually part of the sealed sensor assembly — which means the sensor has to be replaced if its internal battery fails. The sensor is activated by the motion of the rotating wheel when the vehicle is being driven, and by changes in air pressure inside the tire.

On most applications, each sensor is individually coded and has its own designated location: RF (Right Front), LF (Left Front), RR (Right Rear) and LR (Left Rear). Some systems may also have an additional sensor in the spare tire.

The signals sent by the pressure sensors inside the tires may be received by the “keyless” entry system on some vehicles, the Powertrain Control Module, the anti-theft system or the TPMS module. The coded signal is broadcast at 125 kHz, or 315 or 434 MHz (depending on the application), and includes the sensor’s location and pressure reading. On most systems, the signal is broadcast every 30 to 60 seconds when the vehicle is traveling faster than 12 to 15 mph.

Despite rumors to the contrary, cell phones, radios, radar detectors, garage door openers and remote starters should have no effect whatsoever on the signals broadcast by the TPMS sensors because all operate at different frequencies. So if a TPMS system is not functioning normally, electromagnetic interference is probably not the cause. The fault is usually a bad sensor or, in some cases, a bad receiver, or the system is confused about which sensor is at which wheel location.

WHAT HAPPENS WHEN A TIRE LOSES PRESSURE?

If tire pressure drops below the threshold for warning the driver, the TPMS system is required to turn on some type of warning light. The least sophisticated TPMS systems will simply turn on a “low tire” warning light, or illuminate a U-shaped icon that is supposed to look like a cross-section of a tire. But these systems don’t tell the driver which tire is low or by how much. That means the driver is supposed to realize there may be a problem with the tires, and to stop and check the pressure in each one to see if any are low. The more sophisticated TPMS systems will illuminate a display that tells the driver exactly which tire is low (RF, LF, RR or LR), and may also show the actual pressure reading for each tire.

TPMS PROBLEMS

TPMS PROBLEMS

The most common problem with direct TPMS systems is loss of signal from any of the tire pressure sensors. This can happen if the transducer or transponder fails, or the sensor’s battery goes dead. Most use a long-life lithium battery with a life expectancy of 5 to 10 years, but they won’t last forever. Consequently, the likelihood of sensor failure goes up with the age of the vehicle.

Note: If a TPMS warning light is blinking, it usually means there is a fault in the system.

In theory, the tires are supposed to wear out before the sensors go dead. Most manufacturers recommend replacing the sensors when the tires are replaced — which isn’t going to sit well with many motorists because some sensors can cost as much as $200 each to replace! And some of these sensors are “dealer-only” parts that are not yet available in the aftermarket.

It’s illegal to disable the TPMS low-pressure warning light. There is no law that says all of the sensors have to work, or that the system has to be fixed if it’s not working properly. But the riskiest thing any shop could do from a liability standpoint would be to disable a TPMS system for a customer who doesn’t want to pay for new sensors.

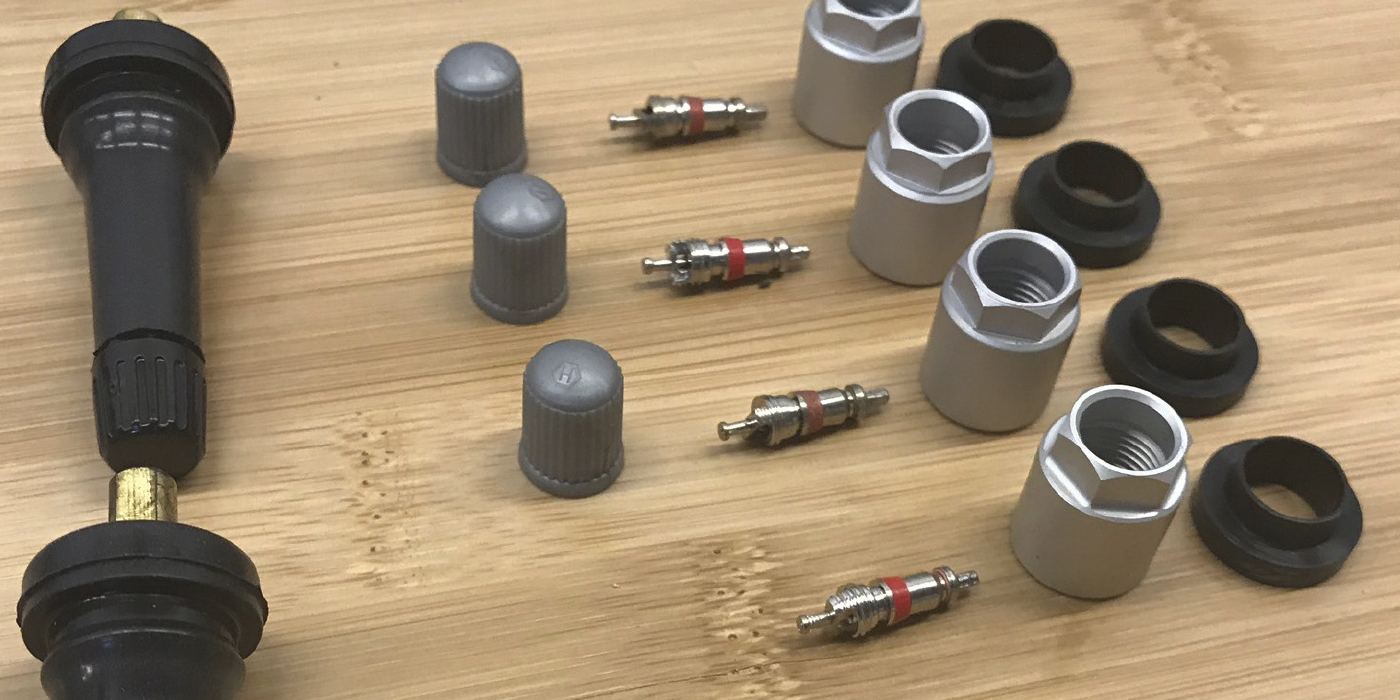

Installing aftermarket wheels and/or tires may also create problems with the factory TPMS. Some pressure sensors won’t fit the holes in aftermarket wheels. There are quite a few different configurations for the valve stems and seals. Depending on the wheel, it may not be possible to reuse the original sensors in an aftermarket wheel. You may even have difficulty finding an aftermarket sensor that will properly fit the hole and seal. Federal law does not require aftermarket wheels and tires to work with the TPMS (though this may change). But you can’t tamper with the warning light, and not many customers would want to drive around with a low tire warning on all the time.

REPLACING SENSORS

Removing a tire pressure sensor is not difficult because the sensor is attached to the valve stem. When you remove the nut that holds the valve stem, the sensor will drop down inside the tire. This should be done after breaking the tire bead from the rim, in case you have to hold the sensor so it doesn’t turn while removing the stem nut.

If a tire is being patched or serviced, and the sensor is still good and will be reused, handle it with care. A sensor can be easily damaged if you drop it on a concrete floor, or if you over-tighten the stem nut when you put it back in.

You do not have to remove the sensor when changing a tire, but you must be careful not to damage the sensor by running the tire changer bead breaker or dismounting tool into it, or dragging the tire bead across the sensor as the tire is removed or mounted on the wheel.

Here’s another tip: When letting the air out of a tire, don’t remove the core from the valve stem. Just depress the core. Why? Because the cores on some sensors don’t come out very well, if at all. If you break it, you bought it.

To reduce the risk of damaging the sensor when dismounting a tire, position the wheel on the tire machine so the valve stem is 180 degrees across from the bead breaker.

If a sensor is removed for any reason, or is being replaced, the seal at the base of the valve stem should always be replaced with a new one to ensure a leak-free seal. A new stem nut should also be used, and the nut must be carefully torqued to specifications using a mini-torque wrench that reads inch pounds or has a scale of 1 to 10 Nm. The nuts typically require very little torque, usually somewhere between 35 and 80 inch-pounds (4 to 9 Nm). Always look up the recommended torque value for the vehicle because the sensors will vary.

Over-tighten the nut and you risk breaking the valve stem. Under-tighten the nut and the valve may leak. Most valve stem-mounted pressure sensors require a special nickel-plated core. Do not use an ordinary brass valve core because it can corrode. Install the valve core carefully so as not to damage the sensor. Use a special torque wrench designed for installing valve cores, and tighten the core to 1.5 to 3.5 inch pounds. The tire can now be inflated to the recommended pressure and balanced as usual.

TPMS RELEARNING PROCEDURES

This is the part that causes the most confusion and headaches. On vehicles where the TPMS has to know the wheel position of each sensor, the system must be programmed or taught the location of each sensor. On a few, such as the new Acura MDX, the system will automatically learn each sensor location. But on most Asian import applications, each sensor has a code that is programmed into the TPMS control module at the factory.

If one or more of these original equipment sensors is later replaced with another OEM or aftermarket sensor, the new sensor code(s) must be manually programmed into the TPMS system using a scan tool. That means a trip to the dealer if you do not have a factory scan tool or an aftermarket scan tool with the appropriate software in your shop. Vehicles that currently require this kind of reprogramming include most Hyundai, Infiniti, Kia, Lexus, Mitsubishi, Nissan, Subaru, Suzuki and Toyota models.

Removing a wheel from a vehicle when doing brake or suspension repairs doesn’t require any special procedures on TPMS-equipped vehicles. Just remount the wheel in the same location as before when you’ve finished the repairs. But if you’re rotating tires, or moving a wheel from one location to another (as when troubleshooting a steering pull or vibration problem), the TPMS will have to be taught the new position of each sensor. This will require a scan tool or a special TPMS test/relearn tool.

Removing a wheel from a vehicle when doing brake or suspension repairs doesn’t require any special procedures on TPMS-equipped vehicles. Just remount the wheel in the same location as before when you’ve finished the repairs. But if you’re rotating tires, or moving a wheel from one location to another (as when troubleshooting a steering pull or vibration problem), the TPMS will have to be taught the new position of each sensor. This will require a scan tool or a special TPMS test/relearn tool.

When removing more than one wheel at a time from a TPMS-equipped vehicle, use a piece of chalk to mark each wheel’s position (RF, LF, RR, LR). That way, you won’t forget which wheel went where and accidentally mount the wheels in the wrong locations.

Aftermarket TPMS testers are available from a number of sources and typically sell for $500 or less. Most of these testers cover a wide range of makes and models (import and domestic), but some may be limited to specific models or types of sensors (such as sensors that operate in continuous mode or modulated mode only).

The tester communicates electronically with the sensors and TPMS. The unit typically activates the pressure sensors so they will broadcast a signal. The unit then programs the TPMS module or receiver in the vehicle so it will recognize which sensor is which (RF, LF, RR, LR). The tool can also be used to verify the operation of each individual sensor and troubleshoot TPMS faults. Many of these tools have a USB port that allows the tool’s software to be updated as needed, and to download information from the tool to a PC for printing or recording. For more advanced diagnostics involving communication problems between the TPMS module in the vehicle and the PCM or keyless entry system, an OEM scan tool or aftermarket professional-grade scan tool with OEM-level software will be needed. A scan tool is also needed for most indirect (ABS) TPMS systems, for diagnostics and resetting the system.

All TPMS systems have self-diagnostic capability and will set a diagnostic trouble code (DTC) if a pressure sensor fails. If you find DTCs for all four pressure sensors, it means the TPMS module has forgotten the locations of the sensors because the vehicle battery has been disconnected or has run down. It could also mean there is a problem with the TPMS or keyless entry system receiver. Refer to the diagnostic flow charts in your service literature when troubleshooting these types of DTCs to avoid unnecessarily replacing parts.

TPMS RESET

If you add air to a low tire, or have repaired or replaced one or more tires, refer to the owner’s manual or service literature to see if a reset procedure is required. This may involve pressing a system reset button and/or driving the vehicle in a straight line above a specified speed for a specified length of time to complete the system reset.

On many Toyotas, for example, there is a reset button inside the glove box. To reset the system, turn the ignition ‘on’, then press and hold the reset button for three seconds. When the TPMS warning light blinks three times, the system is reset. Wait at least five seconds before turning the ignition ‘off’ so the system will recognize the new tire pressure readings.

On a Toyota Land Cruiser, there is a Main/2nd switch that allows the vehicle owner to use two different sets of wheels and tires (on-road and off-road). The switch tells the TPMS which set of sensors to look at using the ID numbers that were programmed in at the factory.

On a 2006 Volkswagen Jetta, the TPMS won’t reset unless the car has been parked for at least 20 minutes. The car must then be driven at 16 mph or faster for at least seven minutes for the system to reset and relearn the new pressure settings. Only then will the TPMS warning light go out.

OTHER SERVICE ISSUES

OTHER SERVICE ISSUES

The TPMS is calibrated for the original equipment wheels and tires, so replacing the OEM parts with aftermarket parts may cause some problems. As mentioned earlier, the OEM sensors may not fit certain aftermarket wheels. Also, if the tire sizes are different and require a different inflation pressure, the TPMS may have to be reprogrammed for the new pressure using a factory scan tool or equivalent (if this is even possible).

If a vehicle has an indirect TPMS with no tire pressure sensors, replacing the original tires and/or wheels with different sizes may upset the operation of TPMS. “Plus sizing” (installing lower-profile tires on larger diameter rims to maintain the same overall tire diameter) may be necessary for the TPMS to function properly if the replacement wheels are larger than the original wheels.