I recently visited a well-known local steakhouse and ordered the Tomahawk steak because it’s the best they have. When the bill came, we had a lively discussion at our table about how the restaurant can make any money when the best they have to offer is priced below their mid-grade steak.

It’s often the same in the repair industry. When we serve up the best tech in our shop to solve tough diagnostic problems, we often fail to charge the “Fair-value” for the work performed.

Many shops today report that diagnostic work is getting much more sophisticated. We can all agree that the pace of technical advancement of vehicle design only increases with each model year.

Often advanced tools, software subscriptions and a technician with the level of skills to successfully put all these elements together are required to arrive at the solution to the customer concern. In many cases, a veteran tech with 10+ years of service and a commitment to ongoing training is the person performing the work.

The target benchmark for technician efficiency in general service is a minimum of 125%, but how often is your top tech out on a “Diagnostic Safari?” Most shops report technician efficiency for diagnostic work hits well below 90%. Even the best technician will come up short on the efficiency benchmark if the work isn’t sold correctly when the advisor interacts with the customer.

Sell Diagnostic Work At The Counter

See if this is familiar: a customer shows up at your shop and is reviewing their concern with your advisor. They’ve got a check engine light along with a rough idle. The customer indicates they stopped at the local parts store and have a code printout of po300, random misfire. In addition, the parts rep said they probably needed a tune-up.

The conversation can head a couple of ways. But in most cases the advisor, whose primary role is to create a great customer experience, estimates a tune-up and one hour of labor time to see what is at the bottom of the random misfire.

At first glance it might seem easy to shift the blame for the lack of profitability of diagnostic work to the advisor. But the advisor can only work within the processes that have been laid out by the shop owner.

If there isn’t a good process in place, the advisor, technician and shop will continue to suffer the wrath of a job poorly sold.

While not a new concept, one solution to increase the effectiveness of selling diagnostic repairs that is taught by top trainers and coaching companies is to sell the individual or set of tests required to arrive at the solution. By doing so, your techs will perform at a high rate of profitability for you and them because they will have a starting and completion point.

The Process

Buffalo Bills coach Sean McDermott consistently focuses the team on the “Process.” Attention to the “Process” is one of the key reasons that the Buffalo Bills went from the laughing stock of the NFL to a true contender in the AFC and NFL as a whole.

Taking a process approach to diagnostic work will propel your team to the top-level of profitability.

First, educate your entire team on the complex nature of diagnostic work. You know that there are thousands of OBD-II DTCs – are your advisors aware of that too?

Powertrain, body, chassis and network codes have a myriad of diagnostic strategies and a highly trained veteran tech is required to accurately determine the source of the DTC.

Change The Dialog With The Customer

The motoring public, the internet and extended service interval marketing have shifted your customer’s belief that we have a ‘Magic Scan Tool” that will quickly and accurately pinpoint what is wrong with their vehicle.

Additionally, it doesn’t help when a customer arrives at your shop stating that they have a check engine light on and your standard operating procedure is to take a quick look and hook up your scanner to see what the issue is. You’ve just reinforced the “Magic Scanner” belief.

Heck, you might as well have a Magic 8 ball or set of Diagnostic Dice – you’re just as likelhy to correctly come up with the answer to the concern!

At this moment it becomes evident just how important it is to have built, established and reinforced a trusting relationship between your customer and your shop! That’s what it’s going to take for your highly skilled advisor to overcome ingrained beliefs.

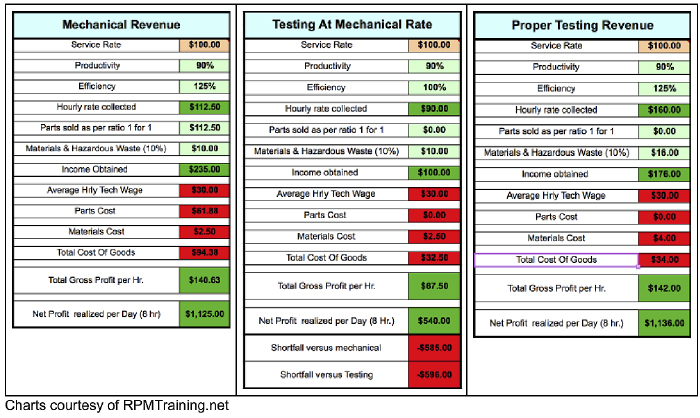

Improving your shop’s profitability stems from effectively collecting the proper gross profit from each service, whether mechanical or diagnostic. The shops we coach have adopted an alternative approach to labor sales, which is having different labor rates depending on the service performed.

When your shop sells general service you collect the gross profit dollars on the labor and parts sales. What is lacking in the sale of diagnostic work are the parts that normally go with a typical repair. By adopting a diagnostic labor factor that is 1.6 times your shop’s mechanical rate, you’ll ensure the total gross profit per hour is maintained.

Profitability in each sector of the shop

We polled shops around the US and confirmed suspicions regarding the order of profitability from the highest to lowest:

- Tires – Lowest investment in tools and least skills required to perform the task

- General service – High level of skill and mid-level investment in tools. Work can generally be performed with hand tools.

- Diagnosis and performance – Highest level of skills and equipment required of any type of work in the shop

The same approach should apply to mechanical diagnostic work, not just DTCs. Reflect on your work over the past month or year and you’re more than likely to realize that you’ve given a ton of hours away. So, if you aren’t collecting for a brake inspection, underhood check or test drive, now’s the time to add some labor time. Your customers don’t work at their job and not receive proper compensation, why should you and your shop?

Put these steps into place as your action plan:

- Estimate and charge for individual or package of tests;

- Utilize diagnostic worksheet;

- Use a tiered approach. Level 1, Level 2 and Level 3 tests;

- Invest in technical training and tools.

Review with your advisors and team that the advanced nature of diagnostic work requires years of technical training and a brilliant technician to accurately arrive at the solution.

Did you ever wonder why the chain stores in the service industry steer away from diagnostic work? Typically because of the level of talent, tools, and lack of profitability in that type of work, it is deemed necessary to either farm it out or decline it altogether. In addition, their business model is set to turn out the highest gross profit dollars per hour. By focusing on tires and general service work, they collect a high rate of gross profit dollars.

If the rewards for a diagnostic job well-done are not reflected in the bottom line, you should rethink your strategy in how you present and charge for that type of service in your shop. No matter what type of repair you sell – mechanical, tires or diagnostic work – each should have its own unique model that ensures your shop’s continued profitability and ultimately everyone’s success.