The most important thing to know is that all brakes make noise. When the friction material makes contact with the rotor, it causes the brake pad and rotor to vibrate. The vibration moves the air around and makes noise.

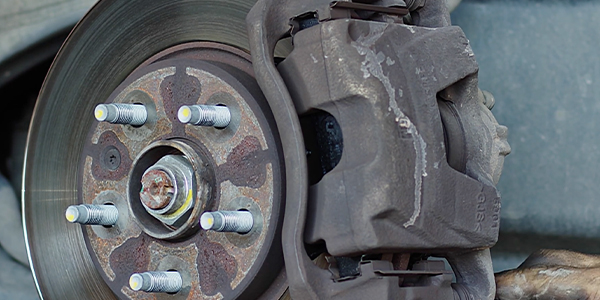

The vibrations can go into the caliper, wheel flange and knuckle. Each of these components alters the vibration and ultimately the noise heard by the driver.

Humans have a limited range of sounds they can hear, so if the noise is out of the range of human ears, there will not be a complaint or comeback (this is typically high-frequency and extremely low-frequency noises).

Shifting and isolating vibrations is how OEMs manage brake noise. They have several tools and methods that are also available to you.

Friction Materials

If friction material is better at keeping a constant level of friction across a broad range of temperatures and conditions, the pad will have quiet performance. Engineers like consistency because they know the frequency of the vibration – this lets them use countermeasures to keep noise out of the range of human hearing.

One tool engineers use is the shape of the friction material on the brake pad. OEMs tune the shape of the brake pad to the overall system, which includes dimensions and design elements like chamfers and slots. Aftermarket brake pad manufacturers will do the same to suit older vehicles and the characteristics of their friction material. Also, how the leading edge of the pad is chamfered can improve the break-in of the pad.

Backing Plates

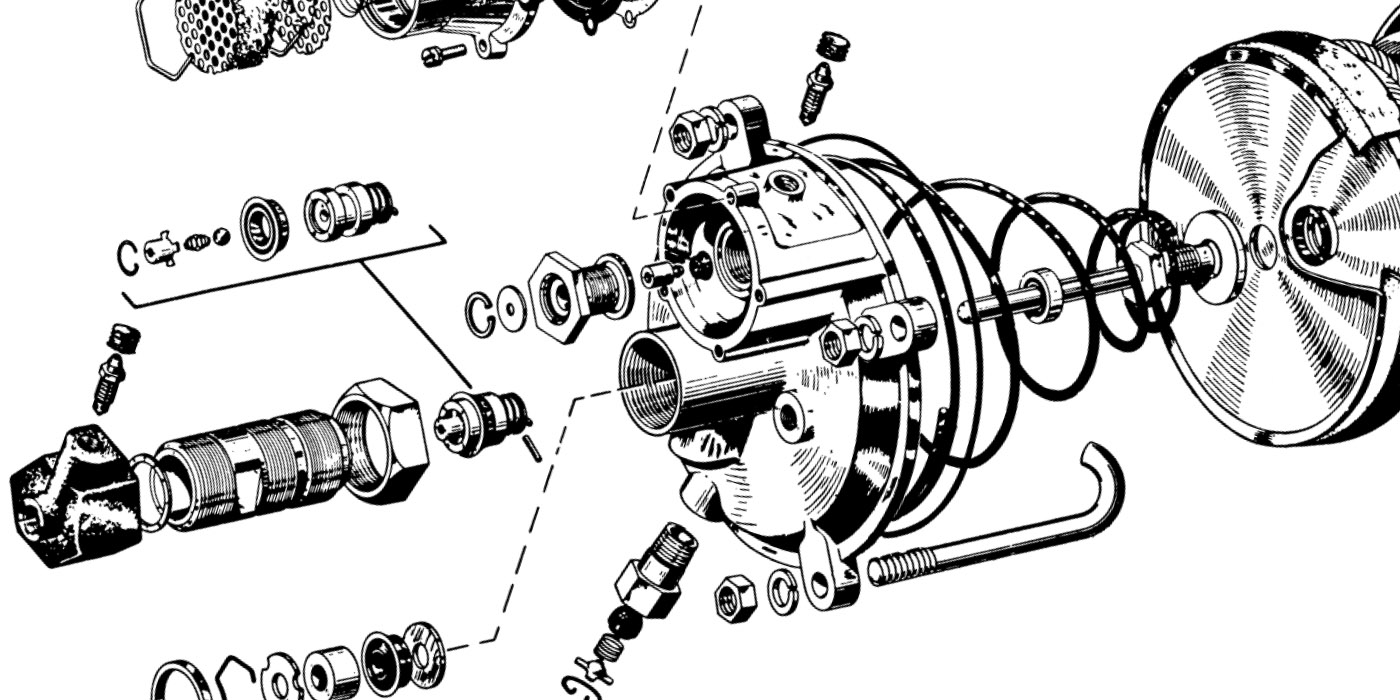

The other part of consistency is how the caliper applies force to the friction material through the backing plate. If a backing plate is flexing, the friction footprint on the rotor is inconsistent. This flex causes vibration and noise. Brake pad manufacturers can either add thickness to the backing plate or change the attachment methods so that the holes for molding are minimized. Some attachment methods eliminate the holes.

This consistency of the friction and footprint can change as the brake pad ages. If the connection between the two is weakened by corrosion, the friction material will delaminate. The separation of the two brake pad components changes how the leading edge of the friction material interacts with the rotor. If the delamination causes a large enough piece of the friction material to break away, it becomes not only a noise problem but a safety issue.

Brake Shims

A quality brake shim can prevent brake noise during the entire life of the brake job. Brake shims can prevent noise by dampening vibration and decoupling the pad from the caliper.

Shims reduce reaction forces transmitted back into the caliper using thick coatings on their surface. Some multi-layered shims use varying grades of metal and elastomeric rubber. The movement of the layers are minimal, but they can have a significant influence over vibration and noise.

The term “full-floating” shim means the shim is not attached to the backing plate with adhesives. The shim is connected to the backing plate with finger clips that grip the sides of the backing plate. For a true floating shim to work, the fingers must grasp onto flat lands on the sides of the backing plate. This allows for a greater range of movement of the shim and a greater variety of noise conditions that can be corrected.

One additional shim that you have access to that the OEM engineers do not is a shim that clips into the piston of the caliper. This piston cushion shim goes between the piston and shim on the pad. This can give an extra layer to prevent noise.

Brake Hardware

You may think that the abutment clips are just anti-rattle clips, but they do a lot more. Abutment clips position the pads in the bracket so they can move freely. When the caliper squeezes, the abutment clips allow the pads to be applied squarely to the rotor to prevent squeaks.

Some abutment clips include fingers that push the pad away from the rotor to reduce drag and reduce noise. Hardware items are consumable components, not only because of rust but because they are springs that can fatigue over time.

Performing a brake job that won’t come back due to noise is not just about making the customer is happy; it is about the financial success of your shop. Time spent on a test drive to duplicate the noise or putting the car on a lift to inspect the brakes is a profitless job. But the time spent on a comeback could have been used instead on a paying job.

When you open your next box of brake pads, how do you know if they might become a noise complaint? This first clue is to look at the quality of the paint, powder coat or galvanized plating on the backing plate. If the outer layer can’t survive the trip from the factory to your shop without being damaged or flaking off in the box, just imagine what will happen when it is installed on the vehicle. Galvanized plating on some brake pads protects beyond exposed backing plate and extends under the friction material. In order to bond the friction material to a galvanized coating, mechanical attachment is required, which improve corrosion resistance and delamination.

Next, look at the shim. If the box claims that it is a floating shim and it is held on with an adhesive, it might be a clue that the manufacturer wanted to give the appearance of a full floating shim without doing their engineering homework.

Some applications might not require a shim or it is attached with adhesives or stakes. Look at the quality of the shim material. If it just a painted piece of metal, chances are it will not do much to reduce noise. If the shim looks like a sandwich of materials, it is a sign the engineering behind the shim might be sound.

SIDEBAR

Two Types Of Friction

So friction is friction, right? Wrong. There are two types of friction when it comes to brakes. Abrasive friction is the breaking of bonds of both the pad material and the cast iron of the disc when the caliper pushes them together. Adherent (or adhesive) pad material forms a very thin transfer layer of pad material on the surface of the rotor. The two surfaces are the same materials and generate friction by breaking or shearing the bonds in the pad.

Abrasive friction is the wearing of the pad and rotor to change forward motion into heat. Both components wear. Semi-met pads and some non-asbestos organics (NAO) use this type of friction.

Adherent (or adhesive) pad material transfers a very thin layer of pad material onto the surface of the rotor. Ceramic and some NAO pads use this type of friction. The transfer layer is bonded to the rotor’s surface and cannot be washed away by water or wheel cleaners. The only way to remove it is by removing it with a brake lathe or it can be altered with abnormal heat. The layer is always being worn and replenished by the brake pad during braking.

So, which is quieter? Both types of friction can make for a quiet brake job depending on the application and installation. Either friction material will be equally noisy if the rotor finish is not correct or the pads do not move freely in the bracket.

SIDEBAR

Brake Lubricants: More Lube = Less Problems

Basting a set of pads or caliper slides in lubricant, no matter how expensive, will not solve a noise issue for an extended period of time. Why? Because the excess lubricant can melt, causing some chemicals to flash off. The melting lubricant can find its way onto the pads, causing a judder problem and longer stopping distances.

Excessive lube can also attract debris and dirt. As the lube hardens over time, it turns to a concrete-like substance that causes slides and calipers to stick. If excessive lubricant finds its way onto the caliper piston’s boot, the lubricant will attract metal particles that can destroy the rubber.

It doesn’t take much to get the job done. Some floating one- and two-piece shims require only a small amount of lubricant between the surfaces of the shim and pad. There is no need to coat the entire back of a brake pad with a lubricant.

Use a silicone-based brake grease for the caliper anchor pins. Make sure it is compatible with all rubber compounds including nitrile, Teflon, nylon and other synthetic rubbers. For the shims, abutment clips and slides, use a synthetic-based boundary-type lubricant that has a high solids content and typically contains a variety of friction-reducing ingredients, such as molybdenum disulfide (moly or MOS2) and graphite.