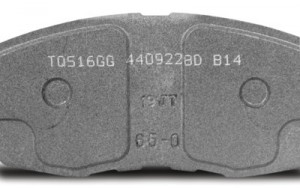

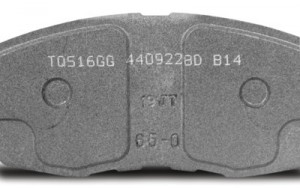

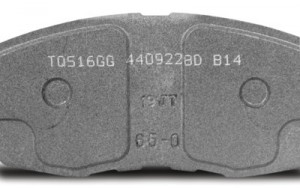

Notice anything different about those edge codes on that set of brake pads you just ordered? If you haven’t yet, you will.

Here’s the deal: Brake friction formulations are now covered by new regulations in California and Washington, which require the phase out of copper and other metals potentially harmful to the environment. As a result, these regulations, while currently limited to two states, are affecting all vehicle service providers across North America as the friction industry shifts to low- and zero-copper formulations in all regions. Additionally, millions of new vehicles equipped with low- or zero-copper brake pads are already being sold throughout the U.S. and Canada.

Not the end: B14 = Environmental compliance marking. “B” refers to the designation. “14” refers to the year the pad was manufactured

New edge codes explained

New edge codes explainedAs part of these changes, all brake pads and shoes manufactured after Jan. 1, 2014, for sale in California are required to have new markings that indicate their compliance with these state regulations regarding friction formulations. On the pads in particular, these markings will be a combination of letters and numbers tacked on to the end of an edge code.

You will continue to see the standard edge code info that’s been in place since the ‘70s, which notes (usually) the manufacturer followed by the “normal” and “hot” temperature friction coefficients.

Now, enter A, B and N — three new compliance designations from the Automotive Aftermarket Suppliers Association (AASA) that correlate with the various phases of the implementation timeline.

A.

A. Asbestiform fibers, less than 0.1% by weight

• Cadmium and its compounds, less than 0.01% by weight

• Chromium (VI)-salts, less than 0.1% by weight

• Lead and its compounds, less than 0.1% by weight

• Mercury and its compounds, less than 0.1% by weight

By 2014 in California and 2015 in Washington, all brake friction materials restricted to no more than 0.1% by weight of asbestiform fibers, chromium, lead and mercury and no more than 0.01% by weight of cadmium.

B.

B. Contains between 0.5% and 5% of copper by weight

• Asbestiform fibers, less than 0.1% by weight

• Cadmium and its compounds, less than 0.01% by weight

• Chromium (VI)-salts, less than 0.1% by weight

• Lead and its compounds, less than 0.1% by weight

• Mercury and its compounds, less than 0.1% by weight

By 2021 in both states, copper in all brake friction materials must be less than 5% by weight.

N.

N. Contains less than 0.5% of copper by weight

• Asbestiform fibers, less than 0.1% by weight

• Cadmium and its compounds, less than 0.01% by weight

• Chromium (VI)-salts, less than 0.1% by weight

• Lead and its compounds, less than 0.1% by weight

• Mercury and its compounds, less than 0.1% by weight

By 2025, California law requires that copper must be less than 0.5% by weight. Washington will adopt a date for 0.5% by weight copper following a feasibility assessment.

Also note that there is an X or WX compliance marking as well that indicates an exemption from the regulation.

In the recommended edge code structure, the numbers that follow the A, B or N are for dating purposes. So, N14 would mean an “N” formulation, manufactured in 2014.

You might also see an optional set of four numbers, placed either before or after the new compliance markings. This series of numbers is the manufacturer’s batch or specific date code — if there is a “1660,” it would mean those pads were produced on the 60th day of 2016.

In addition to the edge codes, the Washington State regulation requires all brake pads and shoes manufactured after Jan. 1, 2015, to have a leafmark icon printed on the packaging to show the level of compliance with the friction material regulation.

What’s this mean for me?

What’s this mean for me?Not much beyond knowing the parts you are using and understanding the language of a brake pad. Maintaining compliance with these regulations is up to the manufacturers.

The A level inventory will be phased out over the designated 10-year implementation timeframe. Bill Hanvey, vice president of programs and member services for the AASA, noted that many suppliers are already well ahead of the timeline, so you have probably already seen B and N leafmarks and edge codes. As mentioned, although these changes were prompted by legislation in California and Washington, these compliant pads will be used across the country. In addition, the Brake Manufacturers Council is working with the EPA to try and make the regulations standard across all 50 states.

Edge Code Refresher

Still not sure what the old edge codes meant? Here’s a quick tutorial.

Edge code: SCB 115 FF

SCB = the code for the manufacturer

115 = brake lining material

FF = Hot and cold coefficients of friction

The coefficient of friction: The Greek letter µ (pronounced “mew”) is a number that is the ratio of the resistive force of friction (Fr) divided by the normal or perpendicular force (Fn) pushing the objects together. It is represented by the equation: m = Fr / Fn.

In the edge code, the first letter notes the normal coefficient of friction (temperatures ranging from 200°F–400°F) and the second letter notes the hot coefficient of friction (ranging from 300°F–650°F).

The edge code letters are directly tied to that formula, where Fn is 150 lbs and Fr is the pressure recorded by the load cell during a normal or hot test sequence. E equals 0.25 to 0.35; F equals 0.35 to 0.45. For example, an average load cell recording of 42 lbs per square inch during a test would produce an m of 0.28 that would relate to an E rating on the edge code. If that’s recorded at both temperatures, an EE would show up on the pad.

New edge codes explained

New edge codes explained A. Asbestiform fibers, less than 0.1% by weight

A. Asbestiform fibers, less than 0.1% by weight N. Contains less than 0.5% of copper by weight

N. Contains less than 0.5% of copper by weight What’s this mean for me?

What’s this mean for me? New edge codes explained

New edge codes explained A. Asbestiform fibers, less than 0.1% by weight

A. Asbestiform fibers, less than 0.1% by weight N. Contains less than 0.5% of copper by weight

N. Contains less than 0.5% of copper by weight What’s this mean for me?

What’s this mean for me?