When a driver hits a pothole or curb hard enough, extreme forces are put onto the balls or rollers and races of the bearing. This can result in the formation of a very small mark on the surfaces. The driver might go 1,000 miles or more before these components start making noise.

This damage is called Brinelling. This surface failure/defect is caused by contact stress that exceeds the material’s hardness limit. Brinell marks may cause the bearing to immediately make noise, and as the marks keep rotating, it could damage the entire bearing. If the impact is great enough, the preload on the bearing can change. This can lead to more damage and noise as debris finds its way into the grease.

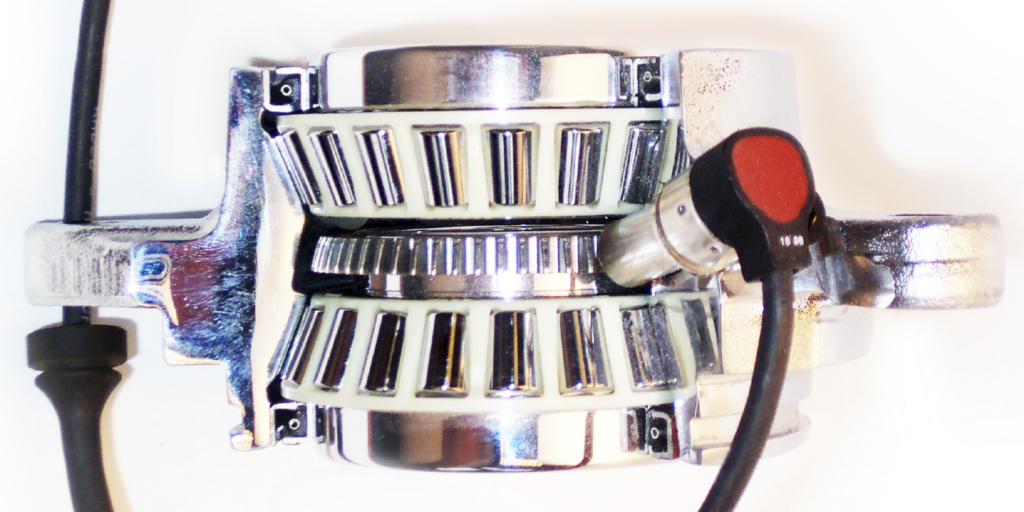

Hub Units

Hub assemblies are unitized, maintenance-free and non-serviceable parts that are preset, pre-greased and pre-sealed, easing installation and increasing product reliability for enhanced performance. These hubs require no maintenance or handling, which eliminates the need for preventive maintenance, grease and/or future adjustments.

Testing

The first step in testing a bad bearing is an audio inspection. The typical sound associated with a bad bearing is a grinding noise that changes with vehicle speed while accelerating above 30 mph. A rumbling, growling, chirping or cyclic noise of any kind from the vicinity of the wheels is a good indication that the bearings need to be inspected without delay.

The most common method of testing wheel bearings is to lift the vehicle and grab the wheel at the 12 o’clock and 6 o’clock positions to feel if there is any noticeable play. By grabbing the wheel at these points, any play in the steering system is eliminated. But, with some hub units, the failure tolerance may be so low that a bad bearing is undetectable by this method. In these cases, a dial-runout gauge could be your best friend.

Replacement

A high-quality bearing is key for performing a comeback-free job. High-quality hub units or bearings typically use higher-quality materials and heat-treating processes that make for harder surfaces. The harder surfaces will not Brinell under hard impacts.

When replacing a hub unit, the replacement unit might feel stiff and difficult to turn. Do not return the bearing. Some hub units and sealed bearings are pre-filled with a special grease that prevents damage while the bearing is being shipped. The grease is designed to have a high viscosity during shipping so the balls or rollers do not destroy the surfaces of the races. After the bearing is installed, certain elements in the grease break down to allow the bearing to turn normally.

Removing some hub units may be very difficult due to corrosion. This can be the case more frequently on vehicles with aluminum knuckles. In some cases, it might be necessary to press the hub from the knuckle off of the vehicle using a puller.

Once the old bearing has been removed, take the time to clean and inspect the bearing bore and axle surfaces that make contact with the bearing. Any debris or imperfections can prevent the bearing from seating properly.

Check the bore for roundness using a snap bore gauge. The gauge should easily rotate in the bore. Any distortion in the bore can cause a new bearing to fail prematurely. It can also make installing the new bearing to the proper depth impossible.

While it may appear to be easier to use an impact wrench, it is not recommended. OEM and bearing manufacturers always recommend using a torque wrench for installation. During removal, an impact wrench can damage the axle nut threads and shock the CV joints. It can also create a false sense of security when adjusting a nut or bolt, which may be under- or over-torqued. This can leave a hub assembly susceptible to failure. Also, in almost all cases, you should use a new axle nut.

Connectors and Harnesses

It is not uncommon to pull a replacement wheel bearing hub with a three-feet harness out of the box. You might be tempted to splice the harness together to avoid removing brittle wheelwell liners. But, no matter how much solder and heat shrink tubing you use, the connection will not be as good.

It is critical that the harness be routed in the same way as the original. If a harness is not routed properly, it can become pinched between the brake and chassis components. Some new hub units include new clips and hardware.

On some vehicles, the wires tend to be brittle and break as a result of fatigue from road vibration and/or steering maneuvers. Replacing the wheel-speed sensor (WSS) wiring harness is usually the recommended fix for these situations.

It is very difficult to repair WSS harnesses since the harness is in an environment that is exposed to water, heat and flying debris. The voltages measured by the next generation of wheel-speed sensors are so small that an alteration in the wiring can cause problems. This can lead to even more ABS diagnostic codes being set.

Some vehicles that use sealed hub units have the wheel-speed sensor and tone ring located between the bearings or on the inner seal. As the bearings wear out or are damaged, the air gap can change as end play increases. This change in air gap can cause “erratic” or “weak” wheel-speed sensor codes.

If you have a scan tool that can access the PIDs and data for the wheel-speed sensors, it is possible to observe play in the bearings as the car corners and brakes. Speeds may drop dramatically when compared to the inputs from the other wheels. If the ABS/ESC system detects this condition, it will disable the system and illuminate the ABS light. If a vehicle has these symptoms, replace the bearing or hub unit, even if it is not making noise or no play is present.