CC:

The BCA Hub video series brings together the latest video tech tips on wheel hubs, bearings, and seals, featuring the experts you trust. Brought to you by BCA Bearings by NTN. Learn more at bcabearings.com.

The classic symptom of a bad wheel bearing is typically a cyclical chirping, squealing, or growling noise that changes proportional to vehicle speed. The sound may disappear at some speeds or occur only at certain speeds. The noise may get worse when turning, or it may disappear momentarily. So it’s challenging to make a diagnosis based on noise alone. Components like tires, CB joints and brakes can mimic wheel bearing noise. This is why interviewing the customer, going for a test drive and performing a rigorous visual inspection are critical to resolving the customer complaint.

Could the noise be in the tires? Tire noise is always proportional to vehicle speed. The noise generated by a tire can be caused by uneven tread patterns, tire construction, and even wheel imbalance. This is typically due to missing tire rotations or in some rare cases, a shifted belt or a damaged construction. Visually inspect the tire and run your hands over the tire’s tread to detect uneven blocks or feathering of the inner or outer shoulders of the tire. Spin the wheel and look for excessive radial run out with your eye if possible.

The tire and wheel assembly can have balance issues that can cause noise proportional to vehicle speed. If you see a wheel that is missing a wheel weight, it could a static or dynamic balance issue. Your best bet might be to use a balancer and see how bad the imbalance is. Also on a balancer, you can measure rim run out. If the wheel assembly has a high spot, as the area comes in contact with the road, it will produce a noise proportional to vehicle speed.

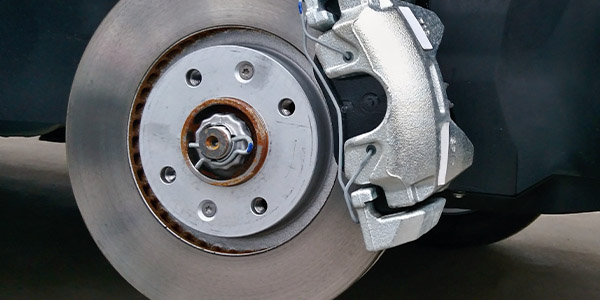

What about the brakes? A caliper that is sticking or a brake pad that is loose and dragging may make a metallic scraping noise as it rubs against the brake rotor or dust shield. The frequency of the noise will also change proportional to vehicle speed, but will often go away or change when the brakes are lightly applied. Noise that occurs only when the driver is braking likely is a brake problem such as worn pads and not a bad wheel bearing.

What about a CV joint? A popping or clicking noise when turning is a classic symptom of a bad outer CV joint. The noise will also increase as the steering angle is increased. Also note the condition of a CV joint boot. If it is torn or leaking, the boot should be replaced regardless of the state of the joint. If the CV joint is noisy, it will need to be replaced.

What about play in the bearing and flange? Raise the vehicle so the wheel is off the ground and then grab at the 12 and six o’clock positions and rock the tire back and forth. As a rule, you should not feel any play or looseness if the vehicle has a sealed wheel bearing cartridge or hubs with a sealed wheel bearing assembly. A little play is normal on older vehicles with serviceable wheel bearings, but a lot of play is not. Refer to the vehicles service specifications for the maximum amount of acceptable play. Wheel bearing play can be measured with a dial indicator by placing the dial indicator against the wheel flange and rocking it back and forth and in and out by hand. As a rule, you should see no more than five thousandths of an inch of run out if the bearings are good.

What about the road surface? Bearing noise should never be intermittent, but the noise can change due to the harmonics and how the driver hears the road noise due to the road surface. This is why the customer interview is so important. Ask the customer what does the noise sound like? When does the noise occur? What speed does the noise occur? Does the noise change when breaking or turning? You should not interrupt the customer or try to diagnose the problem noise during the interview. Always take notes. If you just write on the repair order, “Customer states they hear wheel bearing noise” or “Check for wheel bearing noise”, you’re probably not going to get a proper diagnosis, and this will typically lead to an unhappy customer and an even unhappy technician. I’m Andrew Markel. Thank you very much.

This video is sponsored by BCA Bearings by NTN.