Applied Vehicles: 2007-’11 Versa (C11)

Applied VINs: 2007-’10: All VINs; and 2011 vehicles built before 3N1(*)C1(*)P(*)BL 465717

Confirm that a noise (clunking, popping or bumping) is coming from the front strut assembly when the steering wheel is turned.

Service Procedure:

1. Remove one of the front suspension coil springs.

2. Use Nissan Brake Cleaner (or equivalent) to clean the top and bottom ends of the spring.

3. Install the Tube-Spr Bottom (gray color) (P/N 55018-ZN90B) onto the bottom end of the spring.

a. Starting at the end of the spring, push the rounded/ trimmed end of the tube onto the spring.

Note: The end of the tube must extend 0-6 mm past the end of the spring.

b. Squeeze/put pressure on the tube to ensure a good bond (there is glue inside the tube).

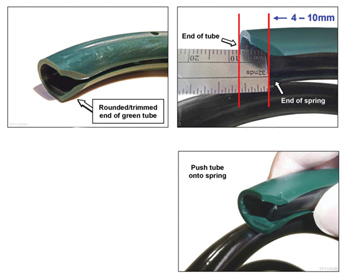

4. Install the Tube-Spr Top (green color) onto the top end of the spring, see Fig. 1.

a. Starting at the end of the spring, push the rounded/ trimmed end of the tube onto the spring.

Note: The end of the tube must extend 4-10 mm past the end of the spring.

b. Squeeze/put pressure on the tube to ensure a good bond (there is glue inside the tube).

5. All 2010 and applicable 2011 Versa: Proceed to step 6.

2007-’09 Versa ONLY: Replace the strut mounting bearing with P/N 54325-JE20C.

6. Reinstall all parts that were removed.

– When re-installing the strut mount insulator, apply Bitmen Wax to the center nut after tightening it to the specified torque.

7. Perform this procedure on the other front suspension coil spring.

Courtesy of ALLDATA.