Application: All floating/sliding calipers.

Problem: One pad is worn, uneven pad wear or abnormal caliper operation.

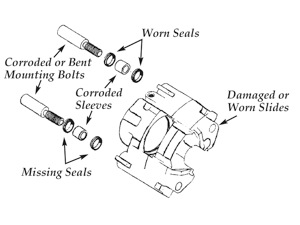

Cause: The caliper is not free to move because of bent or binding mounting pins, worn slides, bent or damaged mounting brackets, swollen or hardened guide seals or lack of lubrication. See Fig. 1.

Solution: Carefully inspect all mounting surfaces and hardware for corrosion, wear or misalignment. Replace all mounting hardware and install a replacement caliper using the proper caliper lubricant.

Installation Tips: The use of high-temperature caliper lubricant is highly recommended for use on all mounting sleeves, bushings, sliding surfaces, pins or bolts. This lubricant effectively reduces noise caused by vibration, ensures proper operation and allows maximum pad and caliper life.

Courtesy of Cardone Industries, Inc.