font-family:”Times New Roman”;} .msochpdefault {mso-style-type:export-only; mso-default-props:yes; font-family:cambria; mso-ascii-font-family:cambria; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:”MS 明朝”; mso-fareast-theme-font:minor-fareast; mso-hansi-font-family:cambria; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:”Times New Roman”; mso-bidi-theme-font:minor-bidi;} @page wordsection1 {size:8.5in 11.0in; margin:1.0in 1.25in 1.0in 1.25in; mso-header-margin:.5in; mso-footer-margin:.5in; mso-paper-source:0;} div.wordsection1 {page:wordsection1;} –>This article will document the P0300 code for a 1996 Mercedes-Benz. A single cylinder misfire has occurred, and the technician decides to clear the code in my presence. I advised that it is a good strategy to maintain the code information for review. It’s clear that misfire activity can be challenging on some ignition systems, and I’ve found through my research that all of the car manufacturers appear to run their monitors in a similar fashion, but it’s still wise to review their service information for the differences and details of their systems.

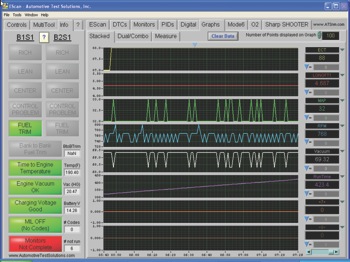

Our diagnostic journey begins with a noticeable misfire activity on our subject vehicle. The tech states that he saw that misfire information on his scan tool pointed to cylinder #6. A review of scan data shows that long-term fuel trim is at or about +5%, see Figure 1; this implies that it may be an ignition issue. This conclusion is drawn from our review of subject vehicles with misfire activity that the ignition misfire does not appear to have a significant impact on fuel trims. (We know that this may create some discussion. If you would like to see an article supporting this claim, email the editor that you are interested in seeing this.)

Our diagnostic journey begins with a noticeable misfire activity on our subject vehicle. The tech states that he saw that misfire information on his scan tool pointed to cylinder #6. A review of scan data shows that long-term fuel trim is at or about +5%, see Figure 1; this implies that it may be an ignition issue. This conclusion is drawn from our review of subject vehicles with misfire activity that the ignition misfire does not appear to have a significant impact on fuel trims. (We know that this may create some discussion. If you would like to see an article supporting this claim, email the editor that you are interested in seeing this.)

This system has a dual ignition coil setup on each cylinder similar to a DIS system. The scan tool shows a spark duration on the 2-5 coil pair of 2.5 ms. The fuel injector for cylinder #6 has been replaced, as this is what the technician believed to be the cause of the misfire.

This system has a dual ignition coil setup on each cylinder similar to a DIS system. The scan tool shows a spark duration on the 2-5 coil pair of 2.5 ms. The fuel injector for cylinder #6 has been replaced, as this is what the technician believed to be the cause of the misfire.

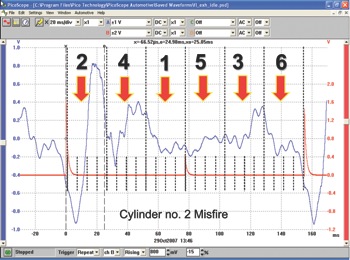

This vehicle was a great opportunity to explore the concept of exhaust waveforms, see Figure 2; this would identify the guilty cylinder for us. I placed the probe in the vehicle’s exhaust and was able to obtain the following waveforms for review. See Figures 3 and 4.

The firing order on this vehicle is 1-5-3-6-2-4. The synch probe has been placed on cylinder #1 as a reference for coil firing. When you reference a six-cylinder engine, the exhaust pulse will occur 240° after the coil fires. The exhaust waveform identified that cylinder #2 had an issue; the question that was still in mind was the cause of the misfire. The coil in cylinder #2 was

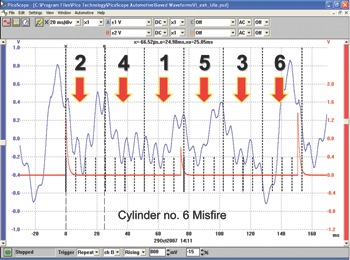

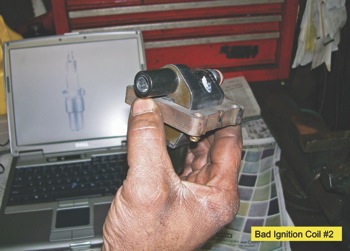

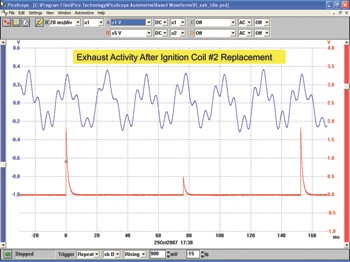

The firing order on this vehicle is 1-5-3-6-2-4. The synch probe has been placed on cylinder #1 as a reference for coil firing. When you reference a six-cylinder engine, the exhaust pulse will occur 240° after the coil fires. The exhaust waveform identified that cylinder #2 had an issue; the question that was still in mind was the cause of the misfire. The coil in cylinder #2 was  swapped to cylinder #6 to verify what we suspected. See Figure 5. It was clear what the problem was after this was done — a bad coil was the cause of our misfire activity. See

swapped to cylinder #6 to verify what we suspected. See Figure 5. It was clear what the problem was after this was done — a bad coil was the cause of our misfire activity. See  Figures 6 and 7. It was interesting to note how the fuel trim and exhaust waveforms proved to be valuable assets in drawing a conclusion to repair.

Figures 6 and 7. It was interesting to note how the fuel trim and exhaust waveforms proved to be valuable assets in drawing a conclusion to repair.

This Pulling Codes case is now solved.