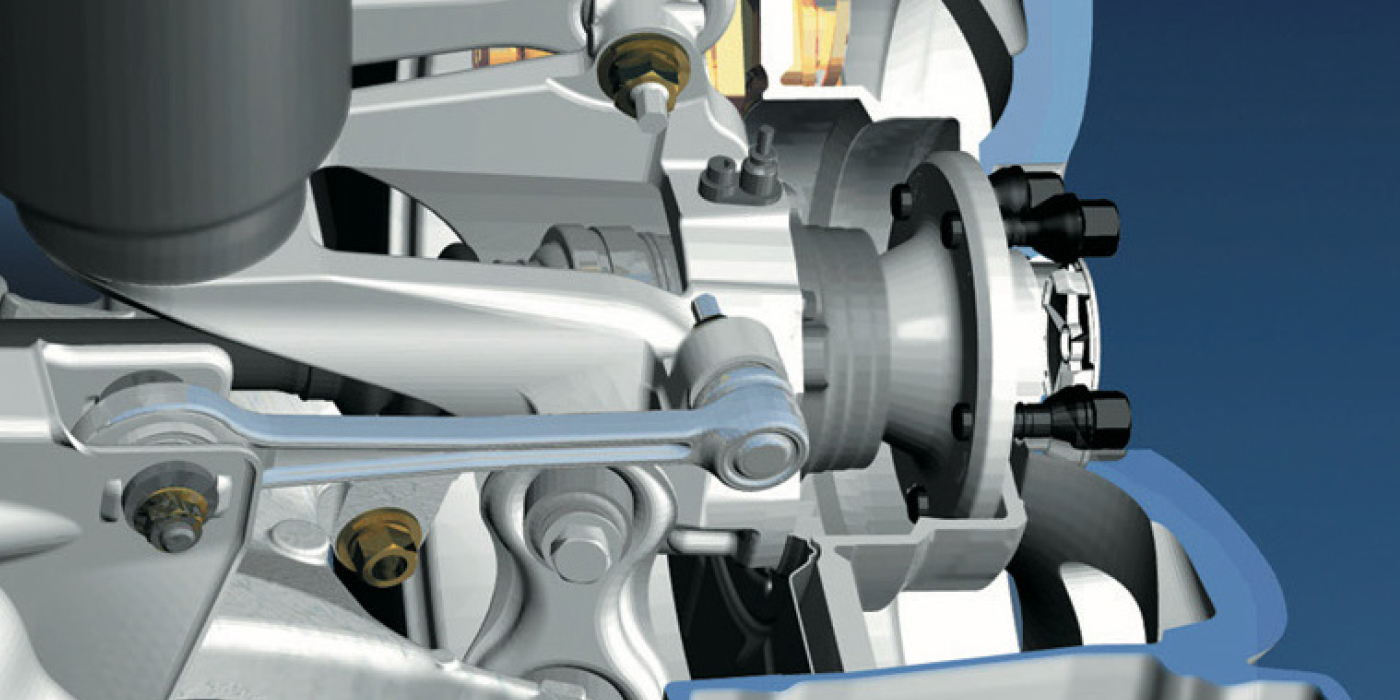

BMW M models with a grey-cast friction ring in a floating arrangement that is connected by pins to the aluminum rotor hat.

The customer’s complaints may include:

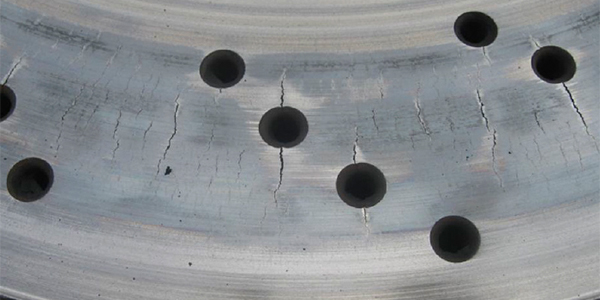

- Visible cracks in the brake discs can be noticed through the wheel opening or during service.

- There are temporary vibrations or steering wheel torsional vibrations during braking.

- After high brake loads, running noises can be heard when applying the brakes.

Visible cracks are caused by high thermal stresses during rapid heating and cooling of the brake discs. Braking from high speed with cold brake components (less than 212 degrees F) increases the likelihood of cracks to form. These hairline surface cracks are usually spread over the entire brake disc friction area, and have no negative influence on the durability or braking performance. The rotors should not be replaced only for their appearance reasons.

When performing routine service on the brake system (pad replacement due to wear), the brake discs should be replaced if surface cracks are found to be greater than 13 mm, or if the brake disc thickness is below the minimum thickness.

Always replace brake discs in pairs (per axle). Install new brake pads when replacing discs. By doing this, the service life of the friction pad surface is increased, and an even material loss is ensured. Vibrations and/or steering wheel torsional vibrations during braking are caused by applying the brakes on discs with minimal to heavy corrosion. These vibrations are most noticeable when braking from high speeds with cold brake components (less than 212 degrees F), and will diminish with normal everyday operation. Parts replacement is not required.

After high brake loads, running noises can be heard when applying the brakes, and may also be heard to a limited extent after the brakes are released (See the note in the Owner’s Manual).

These noises are reduced during normal everyday operation, due to further erosion of the brake pad friction lining.

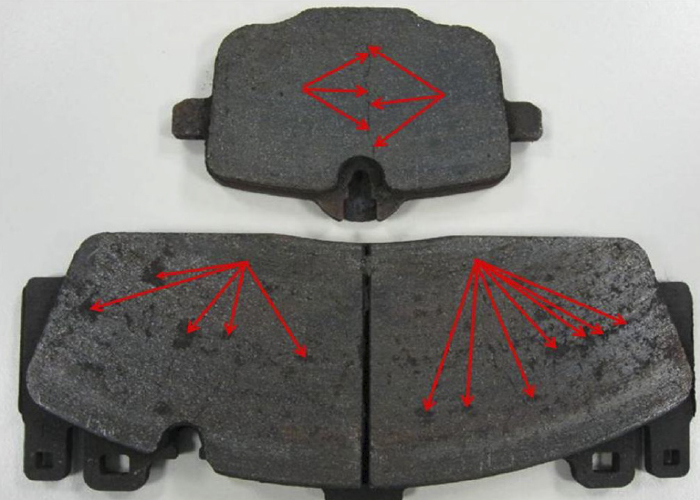

Visible surface cracks or crater-like recesses on the brake pad surface are caused by a minor difference in the material of the pad lining, which will decrease with further operation and should not be replaced due to their appearance.