Service Procedure:

Note: Before proceeding with any of the following steps, check the overall condition of the brakes. Verify that the brake discs and brake pads have not reached their wear limits, and if serviced according to the following procedure, will not reach their wear limits as a result of this procedure.

Warning: Never use compressed air to clean brake dust from a brake system. Use proper eye and respiratory protection devices when servicing brake systems.

Applicable Models:

2003 – 2007 TT

2006 – 2007 A3

1996 – 2007 A4

1998 – 2007 A6

All A8

Q7 1997 – 2007

Required Materials:

Plastilube Moly3 or suitable equivalent

Brake Disc Cleaning:

1. With the wheels removed, mark the position of each brake disc in relation to the hub so that the brake discs can be reinstalled in the same position. Work on one brake at a time to avoid mixing up parts.

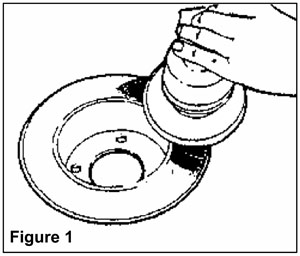

2. Using a power disc-type sander with an 80-grit sanding disc, clean both sides of the removed brake disc (see Figure 1).

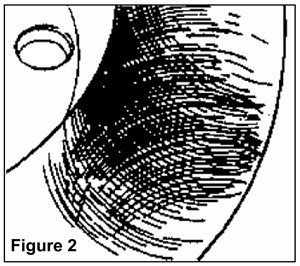

3. This should result in a crosshatch pattern (see Figure 2).

4. Lightly sand the brake disc in a clockwise direction using the leading edge of the sanding disc. Then, continue sanding in a clockwise direction using the trailing edge of the sanding disc.

4. Lightly sand the brake disc in a clockwise direction using the leading edge of the sanding disc. Then, continue sanding in a clockwise direction using the trailing edge of the sanding disc.

Brake Pad Cleaning:

1. Some front/rear brake pads may have an adhesive (sticky) backing, which helps adhere the brake pad to the brake caliper. If the vehicle is equipped with this type of a pad, remove this sticky backing and any residual adhesive from the backing plate of the brake pad and brake caliper. Some front/rear brake pads have an anti-vibration backing plate (non-sticky). Do not remove this type of backing.

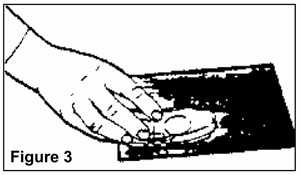

2. Clean the face of the pad with sandpaper (see Figure 3).

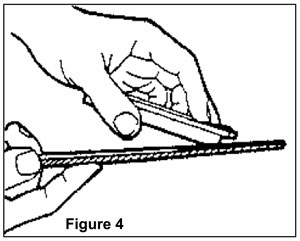

3. Slightly chamfer edges with a file (see Figure 4).

3. Slightly chamfer edges with a file (see Figure 4).

Brake Caliper, Cleaning:

Brake Caliper, Cleaning:

Note: The following steps require a thin coat of Plastilube Moly3 (or suitable equivalent) high-temperature brake grease to be applied to various areas of the brake components. This grease must never come in contact with the brake friction surfaces of the pads or discs.

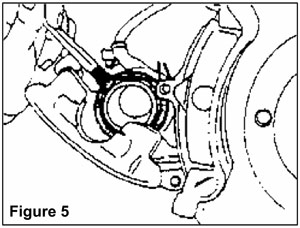

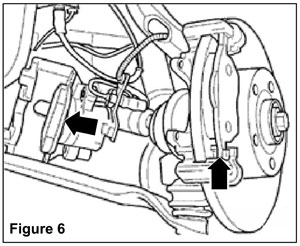

1. Thoroughly clean all contact points where the brake pad backing plate makes contact with the brake caliper and/or the brake carrier (see Figures 5 and 6).

1. Thoroughly clean all contact points where the brake pad backing plate makes contact with the brake caliper and/or the brake carrier (see Figures 5 and 6).

Reassembly:

1. Reinstall the brake discs in their original position. (See Brake Disc Cleaning, Step 1.)

2. Prior to reinstalling the brake pads, apply a thin coat of Plastilube Moly3 (or suitable equivalent) high-temperature brake grease to all contact points (Figure 6) where the brake pad backing plate makes contact with the brake caliper and/or the brake carrier.

3. For brake pads that have springs (common on rear brake pads), apply a thin coat of Plastilube Moly3 high-temperature grease to the springs where they make contact with the brake caliper.

Courtesy of ALLDATA: Ed Dorowski, ALLDATA Editor and Jeff Webster, ALLDATA Technical writer.