The 2008-current fifth-generation Dodge Caravan and Chrysler Town and Country comprise one of the longest running vehicle platforms on the planet. The brake system is your basic four-wheel disc with the parking brake on the calipers, but don’t let that lull you into complacency. If you don’t address issues like runout and the caliper brackets when replacing the brake pads, it will result in a comeback.

Brake Fluid

Dodge requires DOT 4 brake fluid for the Caravan. This type of brake fluid is recommended because of the kinematic viscosity requirements of ABS and ESC systems. Also, the soft seals inside the master cylinder are designed of DOT 4.

Brake Booster

The V6 engine uses a vacuum pump to augment normal engine vacuum. Control of the vacuum pump is provided by the PCM. A two-wire electrical connector is used to receive power and ground for the vacuum pump. Operating voltage is between 9V – 16V. Some vehicles with the auxiliary vacuum pump may store the code DTC P1479, for a brake vacuum system malfunction. Sometimes this code can be set erroneously due to sudden changes in engine vacuum or even condensation build-up. To check the vacuum pump, it will require the use of a scan tool that can perform the bi-directional test for the pump.

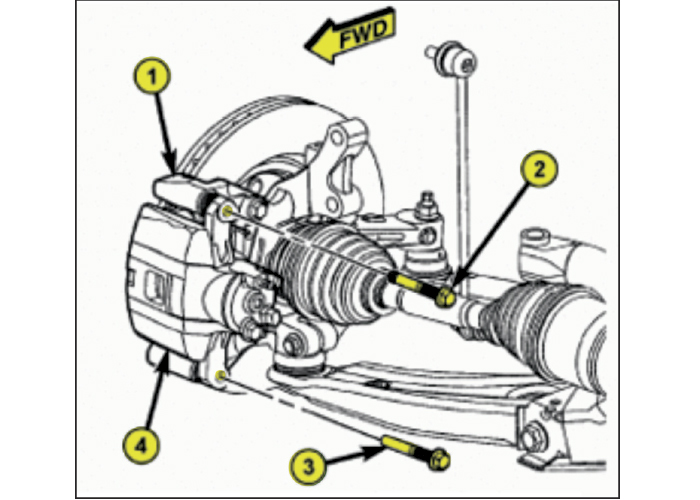

Front Brakes

Always use a premium pad set with new hardware when the pads are replaced. The stock front disc brakes are equipped with an audible wear indicator on the left side inboard brake pad only. The right-side pads do not include an audible wear indicator. Rear disc brakes are equipped with audible wear indicators on both left side and right-side inboard pads.

Rear Brakes

The rear calipers have an integrated parking brake in the caliper. Turning the caliper piston will retract the caliper. Parking Brake Adjustment The parking brake lever is an automatic-adjusting type that continuously applies minimal tension to the parking brake cables to keep them in adjustment at all times.

1. Wipe the front parking brake cable strand clean at the intermediate bracket area. Do not use any type of sharp instrument directly on the cable strand to hold it in place. Damage to the cable strand or coating can occur.

2. Clamp an appropriate pair of pliers on the front parking brake cable button only and pull the cable strand rearward until it stops, then grasp the front cable strand and hold it in this position. Remove the pliers from the button.

3. While holding the front cable in this position, install the equalizer (attached to both rear cables) on the front parking brake cable.

4. Release the grasp on the front parking brake cable.

5. Apply and release the parking brake lever one time. This will seat the parking brake cables and allow the auto adjuster in the parking brake lever mechanism to correctly tension the parking brake cables.

Torque Specs

• Front Guide Pin: 26ft/lbs.

• Caliper Bracket Bolt: 125ft/lbs.

• Rear Guide Pin: 26ft/lbs.

• Caliper Bracket Bolt: 100 ft/lbs

• Bleeding Sequence: Left rear – Right front – Right rear – Left front.