1. Every time a stem-mounted TPMS sensor is removed from a rim, it must be serviced, no ifs, ands or buts. This goes for sensors that are six months old to six years old. Do not reuse seals or stems.

2. Always use a new kit. The typical kit includes a nut, valve core, grommets and valve cap. Each component has a specific function and lifespan that is not only determined by time, but what happens when it is installed.

3. Buy an assortment of TPMS sensor service kits. If your shop even sells a few tires a week, your shop should stock an assortment of service kits. Most tire product suppliers have assortments or cabinets filled with the kits you will need to most. Not having the parts to service sensors might result in a car stuck in a bay that could be used for other repairs.

4. Never reuse the nut. TPMS nuts are designed in anodized aluminum to eliminate the contact of two dissimilar metals that would create galvanic corrosion and material deterioration. The nut has a bonded lubricant to help provide the proper torque required for seating a new grommet, in addition to the engineered advantages. If a nut is reused, the anodized surface maybe scratched away and corrosion may occur between the sensor, wheel and stem. It may even make the nut impossible to torque to the correct specifications or remove due to corrosion on the threads.

5. Never reuse the seals/grommets. On the sensor and nut, two grommets seal the sensor and nut to the wheel.

Grommets conform to the mating surface of the rim. The instant the nut is torqued, it starts to take on the shape of the surfaces it is sealing against. This memory can not be erased. If the seal is reused, it could cause a slow leak.

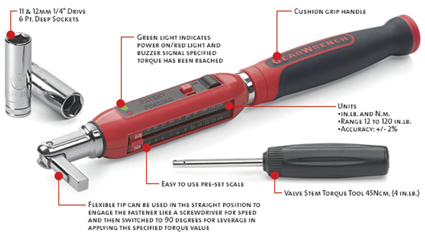

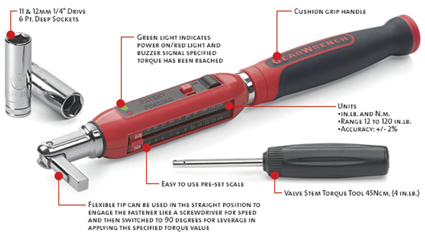

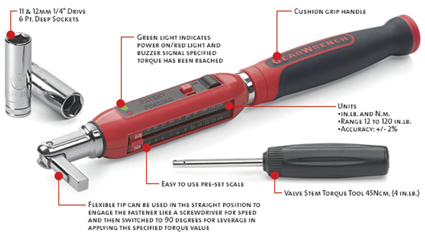

6. Always Use a Torque Wrench. As stated in commandment 4, the nut and grommet seals are one-use items. The torque specifications are measured in inch-pounds and not foot-pounds for a reason. The nuts are made of aluminum and will strip. The hollow stems can take only so much abuse before they break.

7. The leak cannot be eliminated by tightening the nut even more. The sealing grommets are engineered to work at a specific torque. Any torque above the specified value will cause the seal to leak. Also, extra force may damage the nut, stem or fracture the sensor body.

8. Never reuse the valve stem. Replacing the valve stem core on TPMS sensors prevents leaks. The elastomeric rubber and plastics degrade over time due to heat. The valve stem is subjected to heat from both the brakes and road. Also, a torque calibrated driver should be used to tighten the valve core.

9. Always use the valve core that is in the kit. A TPMS valve core is nickel-plated and prevents galvanic corrosion and ensures integrity of the primary seal. To prevent galvanic corrosion, never use a brass valve core with an aluminum TPMS sensor. Instead, always use a nickel-plated valve core with an aluminum TPMS sensor. It is usually the correct one in the kit. If the wrong valve core is used, accelerated galvanic corrosion could result in the core becoming “frozen” and seized, stuck in the stem and unable to be removed. Also, TPMS valve cores have special Teflon coatings that help seat and seal the stem.

10. Set the Correct Tire Pressure. Seasonal temperature change can dramatically alter tire pressure, which can cause the tire pressure warning lamp to illuminate. “Cold” tire pressure, as shown on the tire pressure label on vehicles, is generally considered to be the pressure in a tire that has not been driven in the past 4 hours and has been parked outdoors. Tire pressure drops about 1 psi for every 10 degrees F drop in ambient temperature. Additionally, tires lose as much as 1.5 psi per month as air escapes the tire and rim naturally.

11. Take extra care when mounting and dismounting tires. When you are using a tire changer, always be aware where the TPMS sensor is located and avoid all possible contact with shovels, bead breakers and tire irons. Also, some Ford sensors are mounted on the rim 180º from the valve stem.