Direct Systems

Direct Systems

4 Runner 2004-2011

Avalon 2007-2011

Camry 2007-2011

Corolla 2007-2009

FJ Cruiser 2008-2011

Highlander 2007-2011

Land Cruiser 2005-2011

Matrix 2007-2011

Prius 2006-2011

RAV4 2006-2011

Scion tC 2007-2011

Sequoia 2004-2011

Sienna 2006-2011

Solara 2007-2009

Sequoia 2005-2011

Tacoma 2005-2011

Tundra 2005-2011

Venza 2009-2011

Yaris 2008-2011

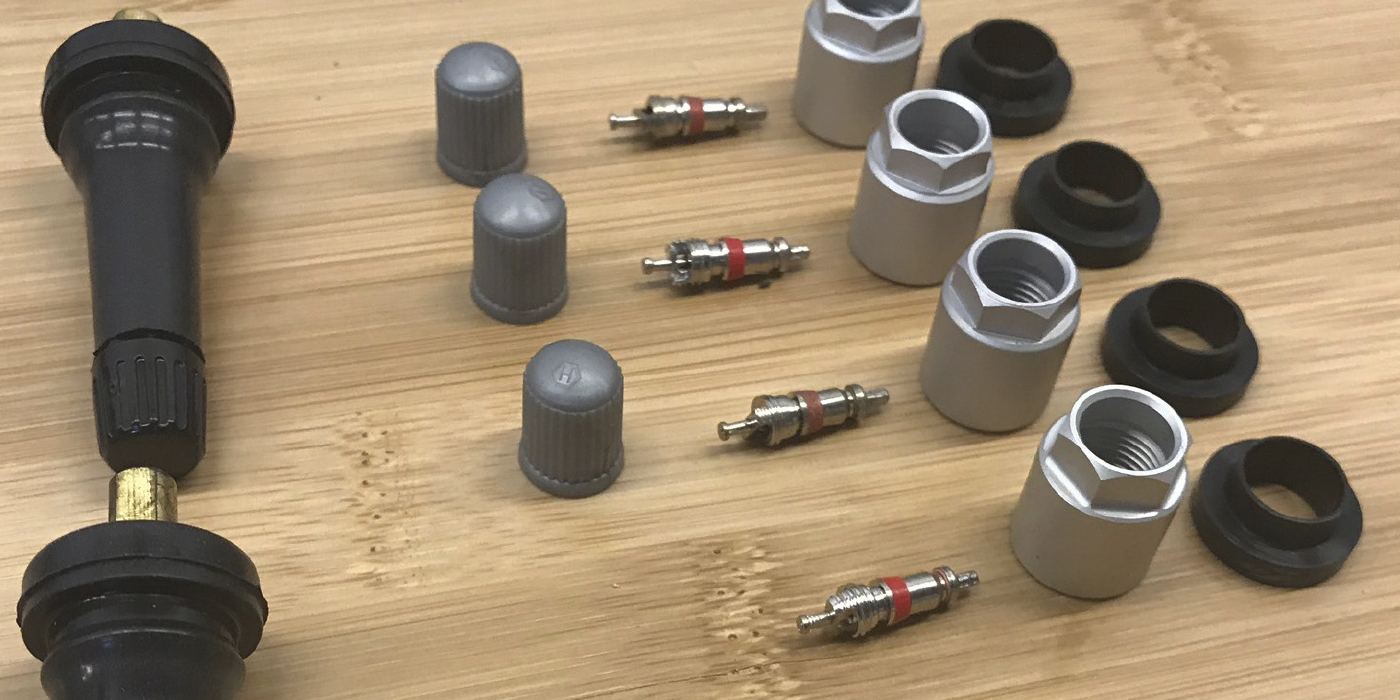

The direct TPMS system for Toyota vehicles uses a button labeled “SET” below the steering column or in the glove box to reset the system. When you press the button, the system is looking for the sensor IDs that are already stored in the memory.

The direct TPMS system for Toyota vehicles uses a button labeled “SET” below the steering column or in the glove box to reset the system. When you press the button, the system is looking for the sensor IDs that are already stored in the memory.

This button is not a magic button saving you from purchasing TPMS tools and training. In fact, this button can get you into even more trouble if you do not know what you are doing.

Reset Procedure

1. Park the vehicle in a safe place and turn the ignition switch to the “LOCK” position.

2. Adjust the pressure of all installed tires to the specified cold tire inflation pressure level.

3. Turn the ignition key to the “ON” position.

4. Push and hold the tire pressure warning reset switch until the tire pressure warning light blinks slowly three times.

5. Leave the system with the ignition switch in “ON” position for a few minutes, and then turn the ignition key to the “LOCK” position.

Typically, systems use a light on the dash and do not display individual pressures (some 2010 models display pressures in the drive information). When the vehicle is started, the light should illuminate for three seconds and go out if the system is functioning normally. If the light stays on, it means that the system has detected a low tire. The inflation of all the tires (sometimes including the spare) should be checked.

If the light flashes for one minute after the ignition is turned on or continues to flash, it is a sign the system has a malfunction that needs to be diagnosed. On some models, the frequency and length of the flashes can be used to diagnose a problem.