Applicable Models:

2003-’06 Camry

2004-’05 Highlander

2004-’06 Solara

2005-’06 Avalon

2006 Highlander HV

Some customers may hear a clunk pop or knock-type noise when turning the steering wheel left or right. Use the following procedure to lubricate the intermediate shaft and address customer concerns.

Repair Procedure:

Steering Intermediate Shaft Removal

Note: Prior to removing the steering intermediate shaft, install a steering wheel holder to ensure that the steering wheel and front wheels remain stationary. Once the intermediate shaft is removed, do not allow the steering wheel to spin freely.

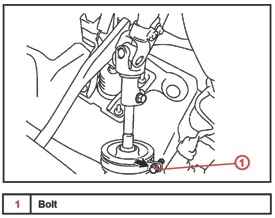

1. Disconnect the steering intermediate shaft sub-assembly. See Fig. 1.

a. Loosen the bolt and remove the clamp from the steering column boot.

b. Separate the steering column hole cover from the boot.

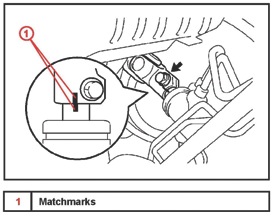

c. Place matchmarks on the steering intermediate shaft sub-assembly and steering gear assembly. See Fig. 2.

d. Remove the bolt and disconnect the steering intermediate shaft sub-assembly.

2. Remove the steering intermediate shaft sub-assembly.

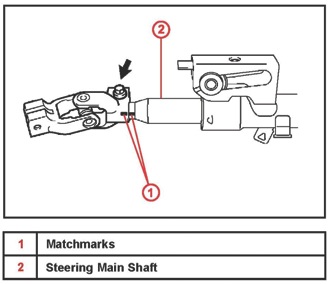

a. Place matchmarks on the steering sliding yoke sub-assembly and steering main shaft assembly (see Fig. 3, 1).

b. Remove the bolt and steering sliding yoke sub-assembly from the steering main shaft assembly (see Fig. 3, 2).

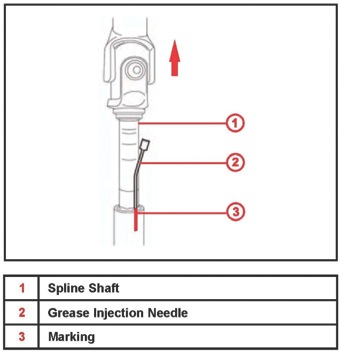

3. Slightly lift the spline shaft upward and expose the splines. See Fig. 4. Two teeth have been machined down to allow a needle to be inserted to apply the lubricant. Once the missing spline has been located, mark it. The other machined spline is located 180° from the original.

4. Insert the needle into the shaft and then install the tube of lubricant to the needle.

5. After attaching lubricant to the needle, squeeze the tube to apply the grease to the splined portion. All of the grease in the tube should be applied.

6. After applying the grease on one side, remove the needle from the shaft. Place the needle into the shaft on the opposite side (180° from the original location) and add lubricant as performed in step 5.

7. Hold the intermediate shaft from the upper and lower portions and compress and extend it about 20 times to ensure that the lubricant is thoroughly distributed inside the splined portion of the intermediate shaft. Note: Make sure that during this process, no foreign objects or material contaminate the grease.

Steering Intermediate Shaft Installation

1. Install the steering intermediate shaft sub-assembly.

a. Align the matchmarks on the steering sliding yoke sub-assembly and the steering main shaft. See Fig. 3.

b. Install the steering sliding yoke sub-assembly with the bolt.

Torque: 35.3 Nm (360 kg-cm, 26 ft.-lbf.)

2. Connect the steering intermediate shaft sub-assembly.

a. Align the matchmarks on the steering intermediate shaft sub-assembly and the steering gear assembly. See Fig. 2.

b. Install the steering intermediate shaft sub-assembly with the bolt.

Torque: 35.3 Nm (360 kg-cm, 26 ft.-lbf.)

c. Install the steering column hole cover to the boot.

d. Connect the clamp to the steering column hole cover boot and tighten the bolt.

3. Road-test the vehicle to ensure that the noise is gone.

Courtesy of ALLDATA.