By Chris Burton, ALLDATA editor and Jeff Webster, ALLDATA technical writer

Applicable Models: 1999-2005 Ford Super Duty F-250 and F-350 trucks

Parts Information

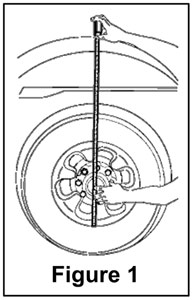

PART NUMBER PART NAME

3C4Z-5A300-AA 1/2” Shim

5C3Z-5742-AA 1” Shim

Service Procedure

Review safety procedures in ALLDATA Repair before beginning.

Note: When verifying the vehicle lean, all equipment must be removed from the vehicle such as tool boxes, caps, bed fuel tanks, etc. The vehicle must be parked on a level surface.

Note: This repair may only be performed on the rear of the vehicle. Do not attempt this procedure on the front of the vehicle.

1. Check for fractured or broken springs, both front and rear.

a. If a spring is fractured, replace the spring and re-evaluate the vehicle. If the condition is corrected, return the vehicle to the customer. If not, proceed to Step 2. Note: If spring replacement is necessary, refer to the part catalog for proper application and part number information.

b. If springs are found to be OK, proceed to Step 2.

2. Check tire pressures and adjust if necessary.

3. Measure the vehicle ride height from wheel lip to top of wheel well opening, at all four corners (see Figure 1).

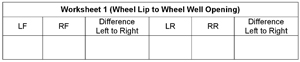

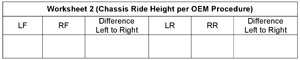

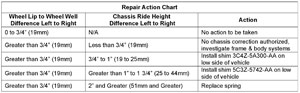

4. Calculate the difference between left to right (use Worksheet 1).

5. Measure chassis ride height per OEM procedure at all four corners and calculate the difference between left to right (use Worksheet 2).

6. Refer to the chart for repair action to take.

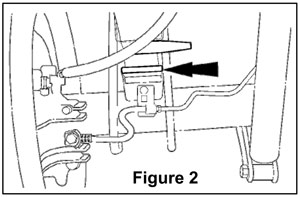

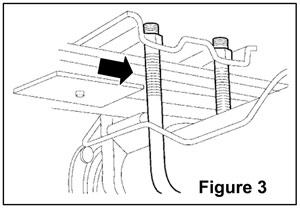

7. If shim installation is needed, install the shim (Figures 2 and 3).

Note: Ensure that the differential guide pin is lined up correctly with the shim and the spring before tightening the U-bolts.

Note: Ensure that the differential guide pin is lined up correctly with the shim and the spring before tightening the U-bolts.

8. Inspect the U-bolts and replace if necessary.

Note: If U-bolt replacement is necessary, refer to part catalog for proper application and part number information.

9. After shim installation re-measure the vehicle ride height per OEM procedure. If the ride height is now greater than 200 mm for a single rear wheel vehicle, or 210 mm for a dual rear wheel vehicle, replace the spring.

Caution: If necessary, install new suspension fasteners. Always replace fasteners with the same part number, or an equivalent part. Do not use a replacement fastener of lesser quality or different design. Torque values must be used as specified in the workshop manual for correct retention of component.