Applied VINs:

2004-’06 all VINs

2007 built before 1N4BA41 E(*)7C 806900

Confirm:

The ABS light is on with one or more of the following DTC stored,

– C1105 – RR RH Sensor 2

– C1110 – Controller Failure

– C1124 – RR LH IN ABS SOL

– C1126 – RR RH IN ABS SOL

and/or the ABS system activates with normal braking.

Service Procedure:

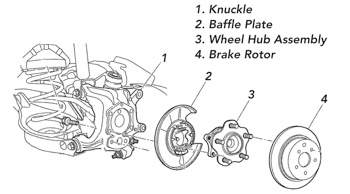

1. Remove only the right rear (passenger side) brake rotor, wheel hub assembly and baffle plate (see Fig. 1).

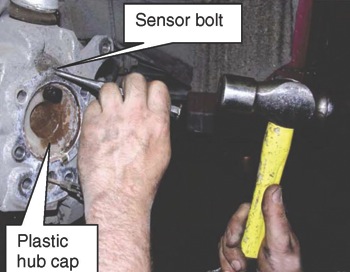

2. Remove the plastic hub cap (see Fig. 2).

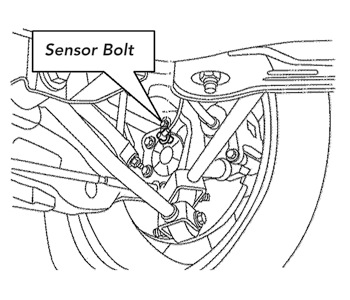

3. Remove the right rear ABS wheel sensor as follows:

a. Apply corrosion penetrant to the sensor bolt.

b. Use a punch and hammer to lightly tap the sensor bolt.

c. Remove the sensor bolt and sensor (see Fig. 3).

4. Clean any corrosion off of the knuckle, baffle plate and wheel hub assembly.

– Use a non-metal brush on the wheel hub assembly. A metal brush may damage components.

– A wire wheel or metal brush can be used on the knuckle and baffle plate.

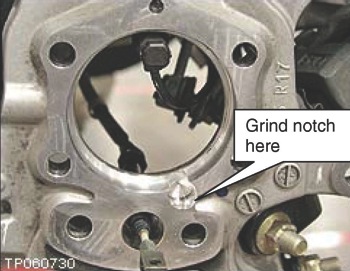

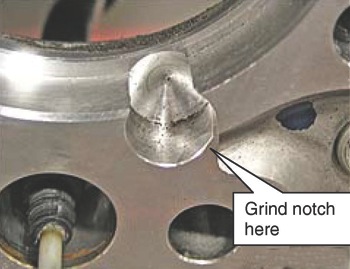

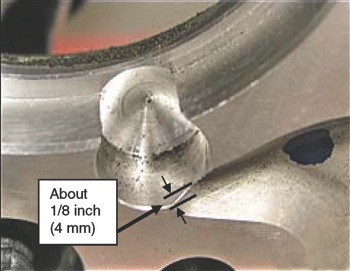

5. Grind or file a notch in the locating hole (see Fig. 4).

Before grinding – see Fig. 5.

After grinding – see Fig. 6.

6. Install the new plastic hub cap.

7. Reassemble all parts removed in reverse order. Make sure to use a new ABS wheel sensor.

8. If code C1124 and/or C1126 was stored, replace the ABS actuator.

9. If you did not replace the ABS actuator in step 8, do the following:

a. Use CONSULT-II to clear all ABS DTCs.

b. Test-drive the vehicle.

c. Recheck for code C1110.

d. If code C1110 is stored, replace the ABS actuator.

10. Test-drive the vehicle; make sure the incident is fixed and the ABS light does not come back on.

Courtesy of ALLDATA.