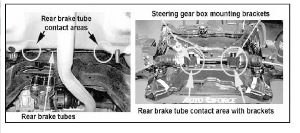

Fig. 1 shows the areas where the rear brake tubes may contact the steering gear box mounting brackets.

Fig. 1 shows the areas where the rear brake tubes may contact the steering gear box mounting brackets.

Affected Vehicles: All 2001-’03 Elantra vehicles produced through Dec. 15, 2002 (both ABS and non-ABS Elantras); all 2003 Tiburon vehicles produced through Feb. 15, 2003 (both ABS and non-ABS Tiburons).

Summary of Procedures:

1. Elantra vehicles with ABS: Treat the left- and right- side (two) rear brake tube contact areas with zinc spray and anti-corrosion wax; then install a white color brake tube clip at each contact area. Refer to Service Procedure below.

2. Elantra vehicles not equipped with ABS: Treat the left-side (one) rear brake tube contact area with zinc spray and anti-corrosion wax; then install a white color brake tube clip at the left side contact area (refer to Identifix service procedure – B).

3. Tiburon vehicles with ABS: Install two black color brake tube clips, one each at the left and the right- side rear brake tube contact areas (refer to Identifix service procedure – C).

4. Tiburon vehicles not equipped with ABS: Install a black color brake tube clip at the left-side rear brake tube contact area (refer to Identifix service procedure – D).

Note: For Tiburon vehicles, install rear brake tube clips only (no chemical treatment is necessary).

Parts Information:

Surface treatment (zinc spray), P/N 00306-2D000

Anti-corrosion wax, P/N 00305-2D000

Brake tube clip (white, Elantra), P/N 58799-2D000

Brake tube clip, (black, Tiburon) P/N 58799-2C000

Service Procedure for Elantra Vehicles with ABS

Caution: Wear eye protection when performing this procedure.

1. Verify the vehicle is affected by identifying the vehicle production date range and VIN.

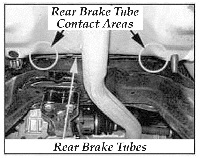

Note: Apply this procedure to both left and right sides at the rear brake tube contact areas. See Fig. 2.

2. Raise the vehicle.

3. Locate the rear brake tube contact areas with the steering gear box mounting brackets.

4. Clean the rear brake tube contact areas using shop air and a rag.

5. Before applying the surface treatment (zinc primer), insert the nozzle into the spray tip.

6. Make a gap between the rear brake tubes and the steering gear box mounting bracket at the contact areas by gently prying with a screwdriver.

Note: If there is not a sufficient gap between the rear brake tubes and the steering gear box mounting bracket, the primer may not cover all of the contact area.

7. Apply the surface treatment on the steering gear box mounting bracket and the rear brake tube contact area evenly (apply three light squirts).

Note: Keep the gap open for at least 3-4 minutes or until the surface treatment is dry.

Repeat application of the surface treatment on the other side of the vehicle at the rear brake tube contact area with the steering gear box mounting bracket.

8. Before applying the anti-corrosion wax (CT-21), insert the nozzle into the spray tip.

9. Evenly apply anti-corrosion wax on the steering gear box mounting bracket and the rear brake tube contact area (apply five to six light squirts).

10. Before installing the brake tube clip, apply anti-corrosion wax inside the clip.

11. Make a gap between the rear brake tubes and the steering gear box mounting bracket using a flathead screwdriver.

12. Install the brake tube clip on the rear brake tubes where the surface treatment and anti-corrosion wax were applied.

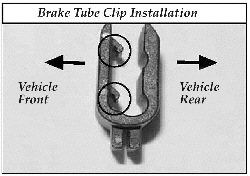

Note: The brake tube clip is directional. The locking tabs inside the clip should face toward the vehicle front. See Fig. 3.

13. Repeat installation of the brake tube clip on the other side of the vehicle.

14. Apply the anti-corrosion wax on the rear brake tubes and brake tube clips on both sides.

15. Lower the vehicle.

Courtesy of Identifix.