The electric motor applies the shoes in the drum hat of the rear disc brake or the caliper parking mechanism. It can be applied manually by the driver or automatically as an anti-theft deterrent when the vehicle is parked and locked. The brake will automatically release when the vehicle is placed in gear.

The electric motor applies the shoes in the drum hat of the rear disc brake or the caliper parking mechanism. It can be applied manually by the driver or automatically as an anti-theft deterrent when the vehicle is parked and locked. The brake will automatically release when the vehicle is placed in gear.

This can be an important feature to the all-wheel drive used on sedans and crossovers. The electric application of the parking brake can be used to hold the vehicle and prevent it from rolling backwards on a hill. The hill-holding feature is incorporated into the Electronic Stability Control (ESC) and uses sensor information from the Controller Area Network (CAN) bus.

Configuration

An electric parking brake can come in two configurations. Both actuate conventional parking brake mechanisms.

An electric parking brake can come in two configurations. Both actuate conventional parking brake mechanisms.

Type 1 is an electric motor and mechanical actuator mechanism mounted to the body of the vehicle. The actuator is connected to the cables for the rear drum-in-hat brake shoes or caliper parking brake mechanism. When the parking brake actuator is activated, the actuator retracts the cables attached to the caliper or the shoe mechanism.

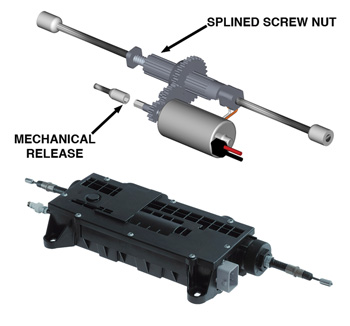

Continental Teves manufacturers a cable-retracting unit used on many vehicles such as Mercedes Benz, Jaguar and Land Rover. A switch is connected to the actuator. The actuator can also be connected to the CAN bus. The actuator is made up of a gear train that rotates a splined screw nut to retract the two cables. It also contains a mechanical release feature as shown in Figure 1.

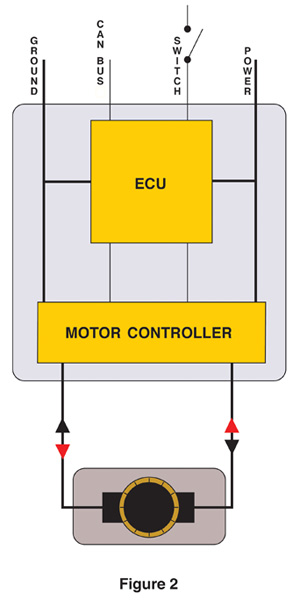

Type 2 uses a motor and gear train attached to the rear caliper parking actuator as shown in Figure 2. This second type will most likely become the standard in that it eliminates the cables to actuate the parking brake and making one electrical and one hydraulic connection at the caliper. The switch is connected to a control module or to the anti-lock brake system (ABS).

The Bosch Automatic Parking Brake (APB-M), Continental Teves and TRW integrated Electric Parking Brake (EPB) systems incorporate a hill-holding feature. If the vehicle stops on an incline, the system maintains braking until the driver has released the brake pedal and the vehicle moves forward. The parking brake can be automatically applied when the vehicle is parked and unoccupied. When the vehicle is started and placed in gear and moves forward, the parking brake is again automatically released.

Controls

Controls

All systems use a separate Electronic Control Unit (ECU) or the ECU function is incorporated into the ABS system. Whether the controller is separate or incorporated into the ABS system, the ECU electronics will contain a bi-directional motor controller circuit connected to the brake actuator motor. Manual apply input will come from the parking brake switch that is directly connected to the controller or ABS.

CAN bus information from the ESC program is responsible for the hill-holding control of the actuator. Shared information for the hill holding feature comes from the yaw, incline and acceleration sensors along with gear selection and steering wheel position. The electric parking brake ECU monitors the operation of the parking brake motor and places that information on the CAN bus. Figure 3 is a block diagram of the controller and motor.

Service

Most GM vehicle with the TRW cable actuated system have the motors located in the passenger-side rear wheel well behind an access panel. On most Ford and Jaguar vehicles, the actuator is in the trunk. It is possible to release the system if the battery is dead. Most of these procedures are outlined in the owners manual that is in the glove box.

If you are doing a brake job on an electric parking brake vehicle like some Audi and VW vehicles, you will need a scan tool with the proper software for the parking brake system or a dedicated tool to reposition the cable retractor or the calipers.

Do not try to reverse polarity or force a piston back. You could damage the gears or motor.