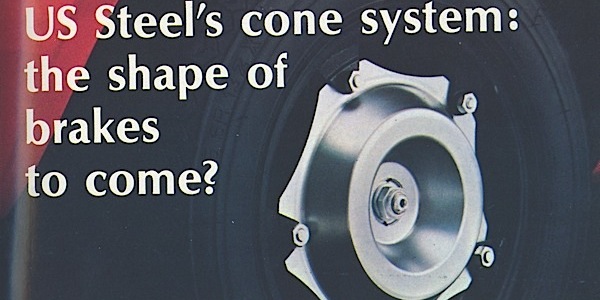

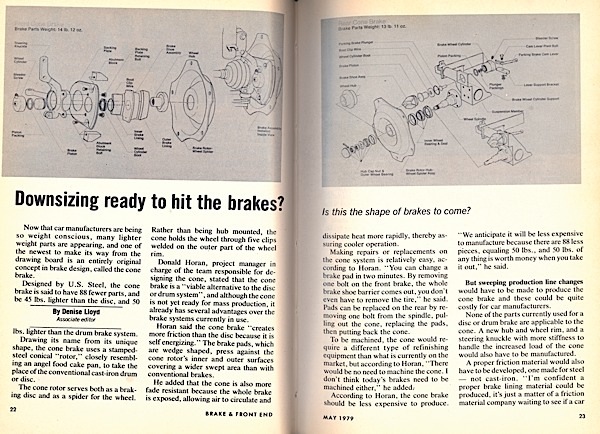

BRAKE & FRONT END, May 1979: It is easy to forget that the most expensive gas prices in U.S. history (when you factor in inflation) were between 1978-1982. During this time, cars got smaller and more fuel efficient. It was one of those rare times in automotive history that automakers were able to sell on fuel efficiency and not horsepower. One of the more radical ideas was the cone brake engineered by U.S. Steel. The stamped steel conical “rotor” was designed to be lighter and help the company sell more steel. While it did work, the main problem was engineering a friction material that was compatible with the surface of the steel. But, the little car was hard to stop and had a ton of pedal travel. The test car had problems with brake travel and force for two reasons.

BRAKE & FRONT END, May 1979: It is easy to forget that the most expensive gas prices in U.S. history (when you factor in inflation) were between 1978-1982. During this time, cars got smaller and more fuel efficient. It was one of those rare times in automotive history that automakers were able to sell on fuel efficiency and not horsepower. One of the more radical ideas was the cone brake engineered by U.S. Steel. The stamped steel conical “rotor” was designed to be lighter and help the company sell more steel. While it did work, the main problem was engineering a friction material that was compatible with the surface of the steel. But, the little car was hard to stop and had a ton of pedal travel. The test car had problems with brake travel and force for two reasons.

First, the cone brakes hydraulics put force on the steering knuckle and bearings causing them to flex. In a conventional brake system, this force is only put on the bridge of the caliper or the inside of the drum. Second, the coefficient of friction for steel is lower than cast iron. US Steel had yet to develop friction materials to deal with this problem. One journalist from Popular Mechanics complained that it was impossible to lock up the brakes.

First, the cone brakes hydraulics put force on the steering knuckle and bearings causing them to flex. In a conventional brake system, this force is only put on the bridge of the caliper or the inside of the drum. Second, the coefficient of friction for steel is lower than cast iron. US Steel had yet to develop friction materials to deal with this problem. One journalist from Popular Mechanics complained that it was impossible to lock up the brakes.