Models:

All (Particularly in the Rust Belt)

Condition:

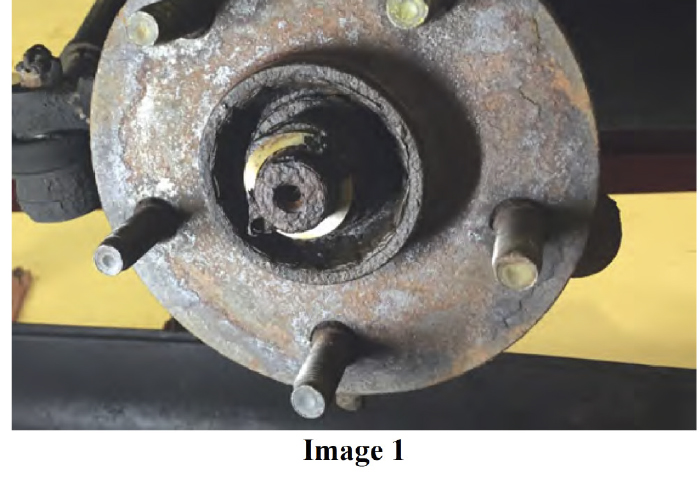

Recently, we had a Jeep Grand Cherokee in our shop for a brake job. Upon removing the rotor, we found one of the rustiest wheel hubs we have ever seen (see Image 1).

Being in the Rust Belt, we are used to cleaning rusty hubs. However, in this case, traditional hub cleaning methods weren’t enough to get the scaled rust off the rotor.

Why is it Important to Clean a Wheel Hub?

Some technicians don’t spend the time to clean the wheel hub during a brake job. It can be a time-consuming process, especially in the Rust Belt where a lot of rust and corrosion can build up on the hub. But, if you skip this step, it can cause an excessive lateral runout of the rotor. This will eventually lead to pedal pulsation.

To illustrate this, we checked the runout of the rotor on the Grand Cherokee we were working on before cleaning the hub. The runout was 0.014”. The specifications for this application was 0.002” or less. Therefore, it is so important to take the time to clean the hub properly.

When cleaning a wheel hub, a lot of technicians use abrasive discs and a wire brush. While this does a good job of cleaning the rotor surface, it doesn’t do a good job of getting the area around the studs. We recommend using a hub resurfacing tool that can go over the studs and clean the hard-to-reach areas (see Image 2). As always, make sure to give the hub a once-over with a wire brush before installing the rotor.

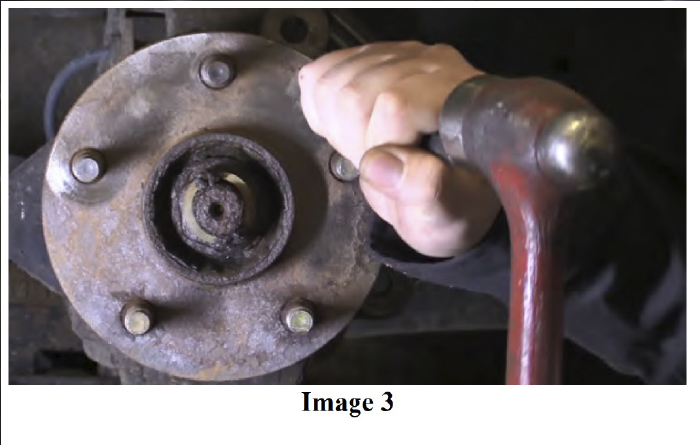

What happens if you go through your regular hub cleaning process, but there is still buildup on the hub? There are a few options. You can use a hammer and a flathead screwdriver or chisel to pop the scaled rust off the hub (see Image 3).

This is an effective, but time-consuming process. However, if you have access to a needle scaler, you can quickly blast the scaled rust off the hub.

Courtesy of Raybestos