It was Saturday, June 11, 2011, at 8:30 in the morning. I had just arrived at an automotive repair facility located in Merriville, IN, owned by a very good friend of mine.

We greeted each other and shared a pleasant conversation that lasted throughout the day. My friend was preparing to go on a well-deserved vacation to see his grandchildren who live out of state and he was very interested in getting a particular vehicle repaired prior to his departure. I listened with all intensity as he shared with me stories of family and devotion. For my colleague and me it was a day of bonding that would ultimately teach me the most valuable of life’s lessons.

The reason for my visit that morning was the challenge of a 2008 Chrysler 300 VIN Code R with a 2.7L engine. This vehicle appeared to operate properly until it reached cruising speed, and then once cruising speed was obtained, the vehicle would actually hiccup and set a pending code for P1128 and P1129. This hiccup could more accurately be defined as a “fishbite” reaction that was felt at cruising speed.

There were also rare occasions where the vehicle would even stall. Once the stall would occur, the vehicle would continue to operate without any other issues pending. Per our test drive, we both verified the concern on our subject vehicle; we then proceeded to the service information to look up the definition of these pending codes that were set. The code descriptions were as follows: “closed loop fueling not achieved” for bank 1 and bank 2.

Our next step was to check for bulletins that might address this strange issue. A search was done in reference to the codes obtained and bulletin number 18-005-11 was indicated. The following statement below provides a general overview:

This bulletin involves flash reprogramming the Powertrain Control Module (PCM) on certain vehicles and then verifying the condition has been corrected. If necessary, your next step will be to add a shim to the crank sensor, then verifying the condition has been corrected and, only if necessary, replacing the flexplate.

This was confusing at first glance to this observer as I could not see a direct correlation between the crank sensor and the fuel-related pending codes that had set. I carefully reviewed the trouble code charts and was able to get the following information as to what should be checked:

• FUEL DELIVERY SYSTEM

• ECT SENSOR, WIRING OR CONNECTORS

• MAP SENSOR, WIRING OR CONNECTORS

• O2 SENSOR, WIRING OR CONNECTORS

• ENGINE MECHANICAL SYSTEM

• POWERTRAIN CONTROL MODULE (PCM)

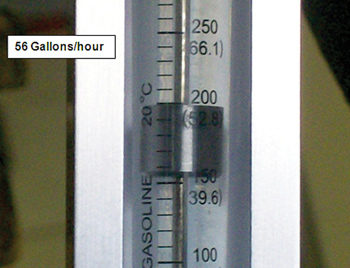

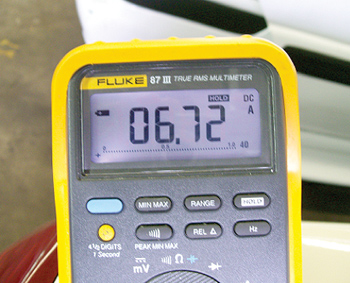

We began our diagnostic journey by checking the fuel system; the pressure, volume and amperage were evaluated. The following data was obtained:

Pressure: 60 psi

Volume: 55 gph

Amperage: 6.72 amps

The fuel system appeared to be working as designed. See Photos 1-3.

Upon a second review of bulletin 18-005-11, it provided the following statement: Note: P0339 – Crankshaft Position Sensor Intermittent must be set along with the other DTCs listed above. If P0339 – Crankshaft Position Sensor Intermittent is not set, then this bulletin does not apply.

Diagnosis

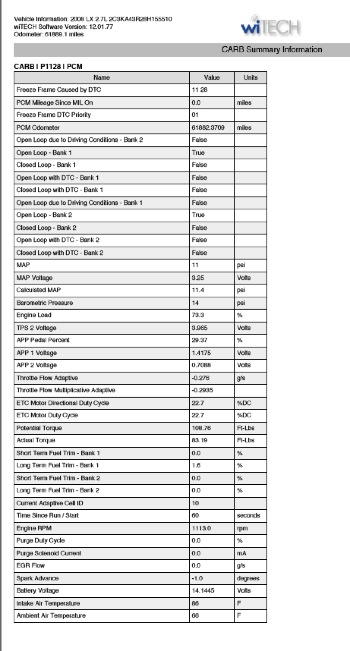

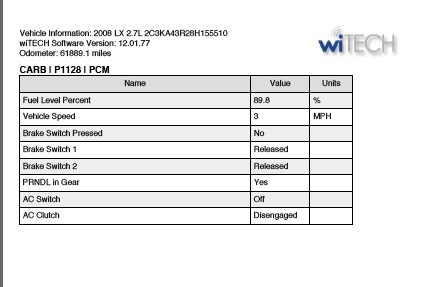

A snapshot was taken of the data when the fault occurs. (If you’d like to see the image, it requires that you have to have wiTECH, however, below is the freeze-frame report.

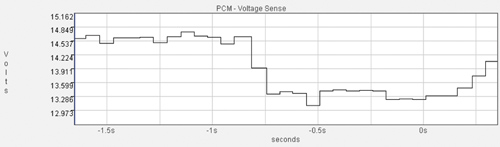

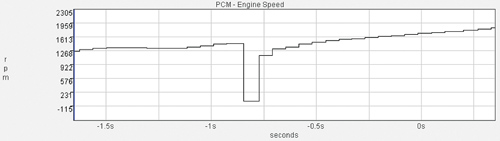

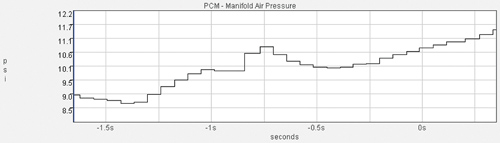

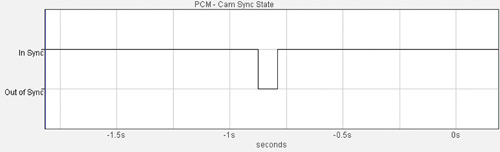

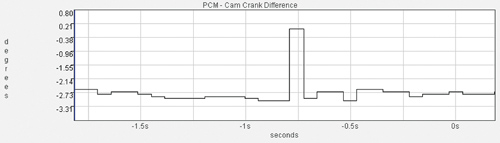

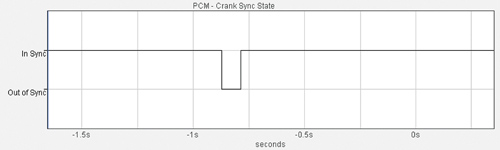

The first observation is a drop in PCM voltage sense from 14.7 volts to 13 volts, Figure 1. The second observation noted was a drop in engine rpm from 1,500 rpm to less than 230 rpm, Figure 2. A third observation yields a reduction in MAP sensor pressure from 10.8 psi to 8.8 psi, Figure 3. The final observations that were noted per the snapshot are three additional PIDs (parameter identification data), namely: cam sync state, crank sync state and cam crank difference. See Figures 4-6.

It was clear that there may be a correlation between how the data was affected per these PIDs. Looking to repair the vehicle that day, my friend inserted a shim and then we test-drove the vehicle again. While the vehicle no longer stalled, the pending codes still came back. It was getting somewhat late and we both decided that we would battle this one once he returned from his trip to see his grandchildren. A few weeks later, I got a call from my friend indicating that he had returned and was ready for battle. We also shared our excitement about attending a training conference on automotive diagnostics that we would attend later in the month.

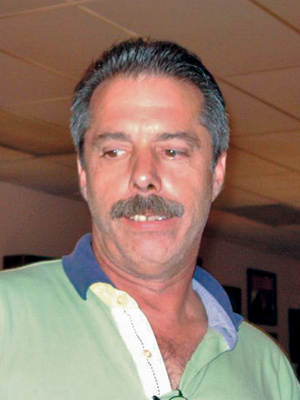

He made me feel that we and others with this common interest were all a part of a diagnostic family. I have always been a strong advocate for training in our industry and he too shared this vision. Prior to our conversation ending that day, he indicated that he had made arrangements for us to look at the subject vehicle again on a Saturday in September 2011. I agreed to our meeting and looked forward to solving this problem and ended our conversation by saying goodbye. I was saddened to find out that later that evening my friend unexpectedly passed away. The snapshot data taken represents the last time we would work together, it is a moment in time. I am in search of this vehicle for evaluation and its conclusion. It is the hope of this observer that I will be able to provide a definite conclusion to the repair in honor of my friend, Gary Zar. I would ask that you join me in reviewing the data provided and send your comments to me at [email protected]. This Pulling Codes case is yet to be solved.

Gary Zar was part of a large automotive diagnostic family. Our training group has spent many weekends in search of additional knowledge in our field. The passion and drive he displayed was second to none. He will truly be missed by all of us.