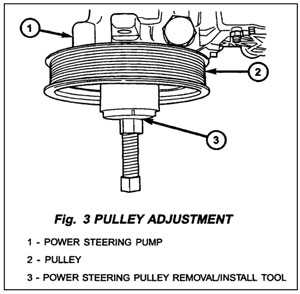

The accessory drive belt can cause a squeaking/chirping sound due to the power steering pulley being pressed too far onto the power steering pump shaft. If the pulley is 0.4 mm or more from the end of the power steering pump shaft this condition will exists.

If the vehicle operator describes or the technician experiences this symptom/condition, perform the Repair Procedure, which involves aligning the power steering pulley flush with the power steering pump shaft.

Applicable Models: 2003-’04 Chrysler PT Cruiser

Note: This bulletin applies to vehicles equipped with a 2.4L and 2.4L Turbo engine built on or before Sept. 11, 2003.

Special Tools/Equipment Required: Pulley Remover/Installer, Matco MST93 or equivalent

Repair Procedure

Review safety procedures in ALLDATA Repair before beginning.

1. Raise the vehicle.

2. Remove the right front tire and wheel assembly.

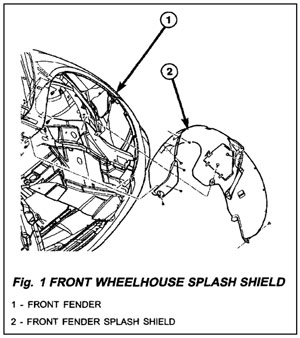

3. Remove the push-in fasteners attaching the splash shield to the frame rail forward of the suspension (see Figure 1).

4. Remove the three lower front screws attaching the wheelhouse splash shield to the front fascia.

5. Relocate the splash shield out of the work area.

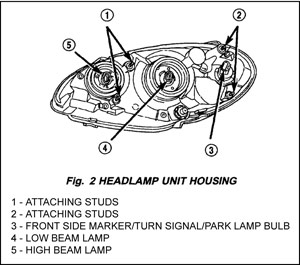

6. Remove the four nuts attaching right headlamp housing (see Figure 2).

7. Remove the right headlamp housing by lowering the right side of the fascia as necessary.

8. Disconnect the wire connector from the headlamp housing (see Figure 2).

9. Install the Matco MST93 puller tool, or equivalent, on the steering pump pulley through the headlamp opening. Tighten the puller screw drive until the pulley is flush with the power steering pump shaft (see Figure 3).

10. Reinstall the right headlamp housing.

11. Reinstall the right splash shield.

12. Reinstall the right front tire and wheel assembly.

Courtesy of ALLDATA.