Tire pressure monitoring systems (TPMS) started off on the wrong foot with both customers and auto repair shops.

Far too many customers came to look at the early high cost of replacement TPMS sensors or the fees for service kits to think that TPMS must just be a cash cow for everybody involved. Those at the installer level, however, are far more likely to see TPMS as a distraction from the things that really matter (and bring in more money) in order to service a tiny and often cranky part that demands far too much attention and resources.

As it turns out, we are all wrong. While TPMS isn’t a promised land, as some of our customers would believe, it can be an incredibly important addition to your list of services.

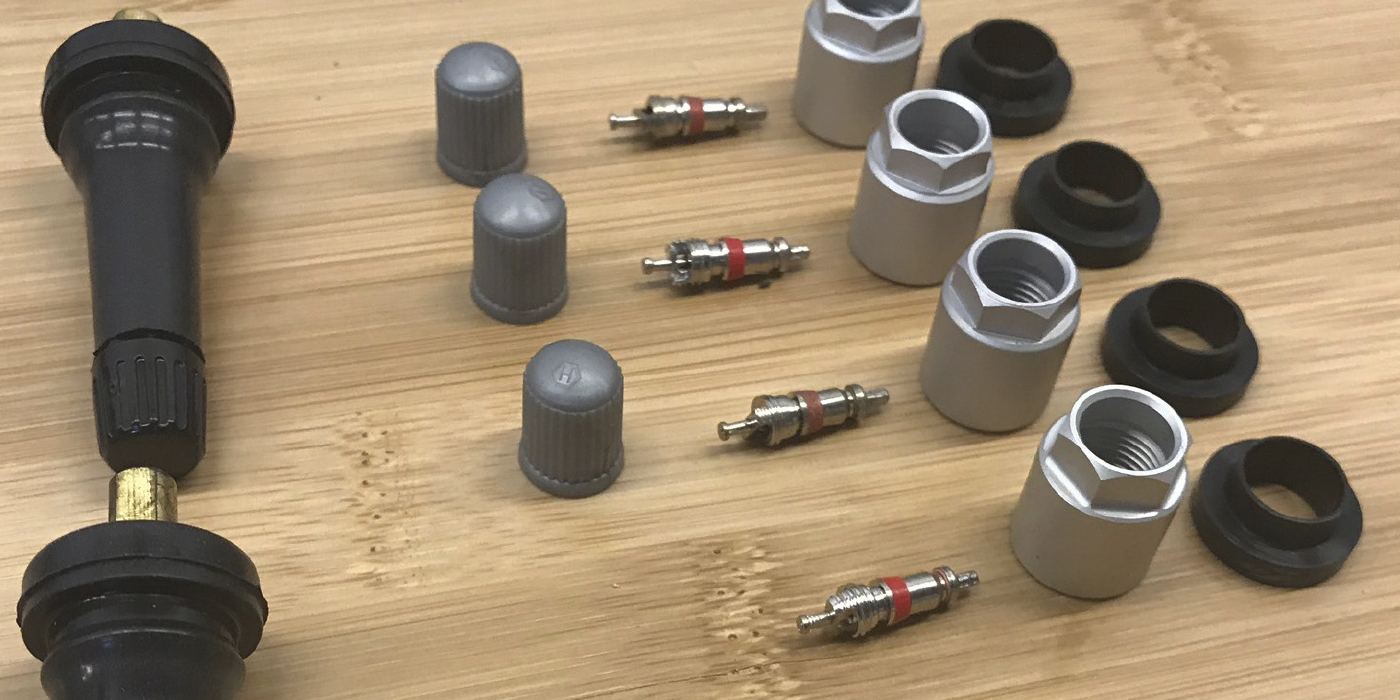

As Matt Winslow, director of speakers and content at Automotive Training Institute, points out, “Today we don’t have ‘valve stem service,’ but we have ‘TPMS rebuild.’ We’re replacing the seal that connects the sensor to the wheel, we have the valve core and we usually have the crush nut that attaches it and so forth. Most shops are charging about $8 for TPMS rebuild and they’re paying about $4 for it, so that’s a new profit center.”

Now while that may not seem like loads of profit, remember that TPMS service kits should be included every time a tire is serviced. That has nothing to do with profit; it’s simply an industry-wide best practice. It has to happen if you’re doing things right – for your customer and your business.

To do things right means leveraging the sales and service of TPMS sensors as a true profit center. That requires a bit of finesse, a few good tools, some training and a willingness to educate your customers.

It All Starts With Pricing

It All Starts With PricingThat process begins with making some decisions about pricing. There are several possible approaches to TPMS pricing, and which one or combination of several is right for your shop depends on how you approach your business and your customers.

Winslow and his colleagues at ATI recommend a form of “Value Meal-style” package pricing, in which the customer is offered a single price which includes the tires themselves and itemized installation-related services such as mounting and balancing, TPMS service and road hazard warranties.

As Frank Rose, a senior consultant for ATI and a shop owner himself, says, “Today, it’s not the tire, but the package. You have to sell the whole package.”

This approach has the advantage of not letting the customer get caught up in too many choices. Rose noted, “A lot of times in the tire business you ask the customer, ‘Do you want these tires, do you want balance, do you want this or that?’ If you ask the customers enough open-ended questions, eventually they’re going to say ‘No.’”

Presenting the entire package as a set of necessary services required in order to maximize their investment gives the customer one single price to consider and prevents them from getting bogged down in choosing from a menu of options.

Some shops take another approach and will roll service kit replacement into mounting and balancing or installation prices. Keeping the service kit maintenance effectively invisible to the customer avoids any conversations in which a customer might decide to save a few dollars by refusing a service that they feel to be unnecessary padding of the bill. The drawback to this approach is that by avoiding the conversation you have also lost the opportunity to educate your customers.

Brian Rigney, general manager at Dill Air Controls, says, “Rolling it into the cost or charging it separately is really up to the stores. Some want to show it as a separate item and explain the value. That way a consumer will realize that this store is doing the right thing, whereas by not listing it they may assume another store is ignoring it.”

On the other hand, John Stratton, aftermarket sales manager at Huf North America, strongly disagrees, “I recommend telling the customer of the service and the reasons behind it instead of hiding it in the bill. Honesty is the best policy when it comes to any service provided to the customer.”

Education is the Key

Education is the Key Taking the time to educate your customers about TPMS can literally turn them from potential antagonists to willing allies in your sales process by convincing them that you’re operating in their best interest. For example, according to a new consumer survey conducted on behalf of Schrader International, 96% of drivers consider underinflated tires a serious safety issue and 89% think properly inflated tires and an automatic warning system could save their life.

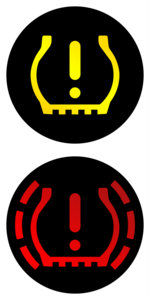

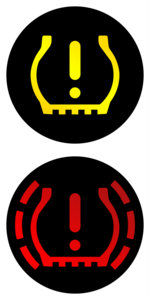

On the other hand, 42% of drivers still cannot accurately identify the TPMS dashboard-warning symbol.

Although this has improved since the last such survey in 2010, when the figure was 46%, this still leaves a great many customers without the most basic (and to drivers, arguably the most important) knowledge about tire pressure monitoring.

That’s bad enough, but if your customers don’t even know what the dashboard light is for, how can you expect them to know why you need to charge them for service kits?

As Paul Wise, director of corporate communications and business development at Schrader notes, “Consumer education (before, during and after TPMS service), as well as a standardized operational TPMS procedure for technicians to follow each and every time, is critical to a shop’s TPMS success.”

One step that can help your customers feel open to being educated in the first place is to essentially ban the use of the term “TPMS” in front of them. TPMS is just a big scary acronym to most people, and even “tire pressure monitoring system” often sounds way too complex to a customer who is not technically oriented.

Instead, talk about “tire pressure sensors” or “tire pressure monitoring” and you will probably find that customers can actually get their heads around the concept and will feel much more comfortable and empowered.

But customer education really begins right after the car rolls into the shop. By now, most folks who deal with TPMS on a regular basis are basically familiar with the concept of “Test Before Touch” as an important way to create an audit trail showing that you are complying with the TREAD Act as well as NHTSA regulations regarding TPMS.

It’s also extremely important because it is the initial entry point into the conversation with the customer. This is where you begin the process of education as well as the process of selling.

Wise explains, “‘Test Before Touch’ is an industry best practice, not only to ensure a repetitive, standardized, efficient TPMS operational procedure, but also to ensure positive TPMS conversations with customers up-front before any service work is done on the vehicle.”

According to Schrader, a good TBT checklist consists of five major steps:

Step 1: Check the TPMS warning symbol on the dashboard

Step 2: Check the valve caps (metal caps should be replaced with plastic)

Step 3: Check the TPMS sensors (with a hand-held scan/diagnostic tool)

Step 4: Print pre-repair audit and documentation

Step 5: With customer now well-informed and with their approval, begin TPMS service.

Once a technician has performed a visual and scan tool check of all four sensors, the results of that audit should be discussed with the customer, preferably in conjunction with a printed audit report. If any of the sensors are not working, then it’s obviously a very good time to discuss replacement. If the techs are worried about damage to the valve stem sensors when they attempt to remove a tire, this is the time to warn the customer of that possibility before any work has taken place.

However, even if everything looks fine and none of the stems are showing signs of corrosion, this is also the perfect time to explain the critical importance of service kits as the best means to preserve sensor integrity.

This is the TPMS conversation that will take place vastly more often than any other, so it is critical to any strategy for leveraging TPMS as a profit center. You must be able to show your customers that service kits are not only in their best interests, but an absolute necessity.

In this type of framework, you also need to be sure that whomever is holding the “TPMS conversation” with the customer is trained to not only handle the technical aspects of the conversation, but also the sales aspects.

If, for example, your technician comes out to discuss the results of the ‘Test Before Touch’ process with the customer, he needs to be able to explain why a valve stem sensor is corroded and in danger of breaking, as well as discuss the importance of preventive service kit maintenance. If the customer is on board with that, great. If the customer is opposed to spending a few dollars more, well then it’s time for further education and selling.

Russ Fuller, owner of Orotek, adds, “The key here is training. All counter people have to become trainers. By educating the public on the benefits of TPMS and keeping it functioning properly each and every time they come in for service, this becomes a common expected charge. Anyone who services tires needs to step up the training on both the sales and installation side in order to stay up with TPMS or be left behind. This is a great chance to add extra revenue with a little extra effort on the training side.”

In this situation, there are all kinds of good techniques that can be used. Many shops use point-of-sale displays provided by sensor manufacturers to show customers why sensor maintenance is so important. One great idea I heard from numerous sources was to keep a jar on the front counter with examples of corroded sensors as an unmistakable visual reminder of what can happen to sensors that are not maintained properly.

Some shops will literally refuse to service the vehicle if the customer refuses TPMS maintenance, although this is certainly something of an extreme measure. Others will refuse to warranty the tires, because, as Stratton pointed out, “The rubber grommet on the metal valve will deteriorate over time just as a rubber valve stem will. If not replaced, the customer runs the risk of slow air pressure leaks or even total failure of the valve.”

To put it simply, you’re trying to get the customer to understand what nearly all of us who work with TPMS valve stems know. As Holloway put it, “Why would you not replace them is the better question.”

Ultimately, the best part about a strategy for leveraging TPMS as a profit center is that it really is entirely honest. You truly are providing a useful, valuable and important service.

Not only is TPMS protecting your customers’ lives, but by performing the proper maintenance every time, you are asking your customers to spend a few dollars now to prevent their expensive sensors from being destroyed by corrosion later. Those maintenance costs are a very real form of insurance.

It All Starts With Pricing

It All Starts With Pricing Education is the Key

Education is the Key  Once a technician has performed a visual and scan tool check of all four sensors, the results of that audit should be discussed with the customer, preferably in conjunction with a printed audit report. If any of the sensors are not working, then it’s obviously a very good time to discuss replacement. If the techs are worried about damage to the valve stem sensors when they attempt to remove a tire, this is the time to warn the customer of that possibility before any work has taken place.

Once a technician has performed a visual and scan tool check of all four sensors, the results of that audit should be discussed with the customer, preferably in conjunction with a printed audit report. If any of the sensors are not working, then it’s obviously a very good time to discuss replacement. If the techs are worried about damage to the valve stem sensors when they attempt to remove a tire, this is the time to warn the customer of that possibility before any work has taken place.