Tesla Wheel Bearing Replacement

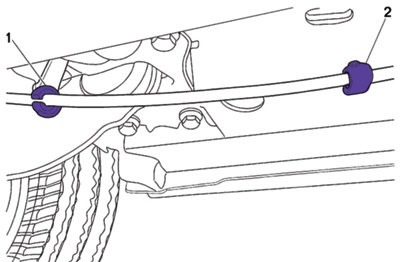

The process of replacing the hub unit on a Tesla is the same as many cars and light trucks.

The most common EVs on the road come from Tesla. The Model S, 3, X and Y share similar drivetrains and wheel-end components like the wheel-bearing hub units.

The process of replacing the hub unit on a Tesla is the same as many cars and light trucks. You do not need insulated tools or gloves to replace chassis parts. The only complications come with initial diagnostics and setting modes for service procedures.

Brake Pad Edge Codes – What Can They Tell You?

The edge code is a language written by engineers, federal entities and industry associations.

Brake Problems

Reducing brake drag on late-model vehicles is not accomplished by a single component; it takes a system.

The Real Cost of Installing Cheap Brake Pads

The brake repair market is starting to become dominated by a “good enough” mentality.

Brake Boosters and Start/Stop Vehicles

For a vacuum brake booster to work, it needs a source of vacuum.

Other Posts

Wheel Speed Sensor and Hub Unit Diagnostics

All wheel speed sensor codes are just the starting points of a diagnosis and not a reason to order a part.

Better Brake Law Update

Learn the latest about the salmon-inspired law.

Identifying Brake Issues With Brake Dust

Brake dust can indicate what could be wrong. This video is sponsored by Auto Value and Bumper to Bumper.

Top 10 Brake Mistakes

Here are the top 10 brake mistakes technicians can make.